Compaction by static pressure combined with impact of pentagonal roller.

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Pentagonal Roller Mechanism

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss how the pentagonal roller contributes to soil compaction. Can anyone describe how impact and static pressure can work together?

I think the static pressure helps push the soil down while the impact breaks it up?

Exactly right! The pentagonal shape allows for greater impact energy that breaks down soil lumps effectively. This action supports kneading, improving soil density. Remember: P-I-C, for Pressure Impact Compaction!

What kind of soil does it work best on?

Great question! Generally, cohesive soils benefit from this type of compaction. Let's summarize: Pentagonal rollers provide static pressure and impactful energy for effective soil densification.

Vibrating Drum

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we have vibrating drums. What is their primary function in compaction projects?

They help level surfaces and smooth out ruts, right?

Exactly! The vibratory motion allows for better settling of the soil particles. Think of it like shaking a jar to mix its contents evenly! Remember V-L-S: Vibrate, Level, Smooth.

Can vibrating drums be used alone for all types of soil?

Not always. They are effective for certain soil types but may not perform well on more granular soils. Keep in mind: Different soils require different compaction methods.

Field Compaction Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss field compaction control. Which factors do you think are critical for effective compaction in the field?

The type of equipment and the moisture content, for sure!

You're correct! The placement water content is crucial for achieving optimal compaction. Another key factor is lift thickness. Who remembers what that means?

Is it how thick the layer of soil is before compacting?

Exactly! A game-changing concept. Also, considering the number of passes with the equipment is pivotal. To remember all these things, use the acronym W-E-L-P: Water content, Equipment, Lift thickness, Passes!

Proctor's Needle

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s explore Proctor’s needle. What do you think this device is used for?

Is it for measuring moisture content in soil?

That's right! It's a rapid measurement tool. Calibration in the lab ensures accuracy in the field. Who can explain its main components?

It has a point, a graduated shank, and a plunger, right?

Exactly! Make sure you remember: P-G-P for Point, Graduated, Plunger! Understanding moisture content is imperative for successful compaction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the importance of compaction in soil mechanics, detailing how a pentagonal roller utilizes static pressure combined with impact to break down soil lumps. It also introduces vibrating drums and plate compactors, along with factors that affect field compaction control, illustrating the methodical approach required for effective soil densification.

Detailed

Compaction is critical in construction to ensure adequate soil density, which affects stability and load-bearing capacity. This section discusses the dual approach of using static pressure along with the unique impact created by pentagonal rollers. The increased energy from the pentagonal roller aids in breaking apart soil clumps, allowing for enhanced kneading and better compaction. Additionally, the section introduces vibrating drums that smooth and level surface irregularities and plate and rammer compactors useful for smaller, less accessible projects. The importance of field compaction control is underscored, with factors such as water content, equipment type, lift thickness, and the number of passes influencing the consistency of compaction. Optimal moisture content (OMC) plays a crucial role in maximizing compaction efficiency, although slight deviations may be acceptable for specific project requirements. Proctor’s needle is also presented as a tool for quick field water content determination, crucial for achieving desired compaction outcomes.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Compaction by Static Pressure

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compaction by static pressure combined with impact of pentagonal roller.

Detailed Explanation

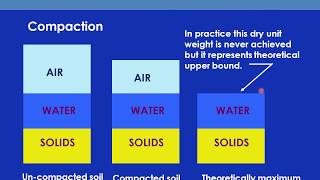

Compaction is the process of densifying soil by applying force to reduce the volume of air and moisture in the soil. When we talk about 'static pressure,' we refer to a steady force applied to the soil. The pentagonal roller adds an 'impact' component, which means it strikes the ground with a certain force, further compressing the soil during this compaction process.

Examples & Analogies

Imagine trying to pack a suitcase. If you just press down on the clothes (static pressure), they might not fit well. However, if you jump on the suitcase (impact), the clothes compress much more effectively. This is similar to how static pressure and impact work together in soil compaction.

Role of the Pentagonal Roller

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Higher impact energy breaks soil lump and provides kneading action.

Detailed Explanation

The pentagonal roller is designed with unique shapes that create higher impact energy when rolling over the ground. This energy is greater than that of a conventional roller. As it moves, it breaks up large clumps of soil ('soil lump') and mixes it, much like kneading dough. This 'kneading' action helps to evenly distribute moisture and particles, fostering a more compact, stable soil structure.

Examples & Analogies

Think about making bread dough. When you knead the dough, you’re working out the lumps and evenly mixing all the ingredients. In the same way, the roller breaks apart the soil lumps and combines the particles, ensuring a smoother and more cohesive material for construction.

Key Concepts

-

Static Pressure: Force applied to compress soil.

-

Impact Energy: The energy delivered during compaction to break down soil lumps.

-

Compaction Equipment: Tools used to densify soil, including pentagonal rollers, vibratory drums, and plate compactors.

-

Placement Water Content: Ideal moisture level for achieving maximum soil density during compaction.

-

Field Control: The management of various factors to ensure effective compaction in field settings.

Examples & Applications

Using a pentagonal roller improves soil compaction effectiveness by breaking clumps during construction.

A vibrating drum levels uneven terrain, making it suitable for road sub-layers.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pentagonal shape rolls for the soil, breaking lumps with impact and toil.

Stories

Imagine a farmer using a pentagonal roller on his land, the lumps of soil breaking apart easily, making way for planting.

Memory Tools

To remember the main compaction factors, think of W-E-L-P: Water, Equipment, Lift, Passes.

Acronyms

P-I-C stands for Pressure, Impact, Compaction regarding the role of pentagonal rollers.

Flash Cards

Glossary

- Pentagonal Roller

A type of roller used in soil compaction that has a pentagon shape to efficiently deliver impact energy.

- Compaction

The process of densifying soil by applying pressure to reduce air voids.

- Vibrating Drum

A roller fitted with a vibratory motion mechanism to effectively level and smooth out soil surfaces.

- Lift Thickness

The thickness of soil layer being compacted at one time.

- Proctor's Needle

A tool used for quick determination of soil water content in the field.

- Placement Water Content

The water content of soil at which compaction is performed in the field.

Reference links

Supplementary resources to enhance your learning experience.