Factors affecting field compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Placement Water Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're focusing on the first key factor affecting field compaction: placement water content. Can anyone tell me why water content is important for compaction?

I think it's because too much or too little water can make the soil either too soft or too rigid.

Exactly! Compaction is most efficient at or near the optimum moisture content. This ensures that the particles can move closer together. Let’s use the acronym 'W.O.R.K.' to remember: Water Optimizes Real Kneading!

What happens if the moisture content is too low or too high?

Good question! When water content is too low, the soil grains don’t stick together well, resulting in loose compaction. Conversely, too much water leads to a muddy mess which can compromise stability during compaction. Remember, we want that 'sweet spot' of moisture!

How does this relate to the lab testing we do?

Lab tests determine the optimal moisture content, so it’s critical to match this when performing field compaction.

So, how do we measure that?

We often use tools like Proctor's Needle! Let's remember it as the 'Quick Check Needle' for rapid moisture checks.

To summarize, optimal placement water content maximizes the effectiveness of field compaction and ensures soil stability.

Equipment Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the types of equipment used in field compaction. Can someone list the common types of compactors?

Isn’t there the impact roller and vibrating drum?

Yes, those are vital! The impact roller uses static pressure combined with impact to achieve compaction, while the vibrating drum levels and smooths surfaces effectively. Remember: 'I.V.' for Impact and Vibration!

What about smaller or tricky areas we can't get to?

Great point! For backfilling trenches or smaller jobs, we use plate and rammer compactors, which are designed for those tight spaces.

How does the choice of equipment affect the compaction process?

The right equipment ensures efficiency and effectiveness. Each type is suited to specific conditions and desired results.

To recap, knowing the right compaction equipment is key to achieving effective field compaction.

Lift Thickness and Number of Passes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve into lift thickness and the number of passes. Why are they important?

I guess thicker lifts could be harder to compact properly?

Exactly! Thicker lifts can lead to insufficient compaction, as not all soil layers get the proper pressure. A general rule is to keep lift thickness between 6 to 12 inches based on equipment capabilities. Remember 'T.H.I.N.' for Thin Helps Improve Notability!

How does the number of passes affect things?

The number of passes refers to how many times the machine goes over the same spot. More passes generally lead to better compaction, but it must be balanced with soil type and conditions.

What soil types need more passes?

Soils with high clay content often require more passes due to their plasticity. To remember, think of 'C.L.A.Y.' - Compacts Less After Yields!

In summary, both lift thickness and the number of passes are crucial for achieving effective compaction in the field.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Field compaction is influenced by several factors that must be understood to ensure effective soil densification. Key aspects include the moisture content during placement, the type of compaction equipment used, the thickness of the lifts, and the number of passes required based on soil type and desired compaction levels.

Detailed

Factors Affecting Field Compaction

Field compaction is crucial for ensuring stability in construction projects, and understanding various factors that influence it can significantly improve outcomes. The effectiveness of compaction is not solely reliant on the equipment but also on the soil's moisture content, lift thickness, and the number of passes.

Key Factors:

- Placement Water Content: This is the water content of soil at the time of compaction. Compaction is most effective when conducted at or near the optimum moisture content, which is typically determined through laboratory testing. Deviations of 1-2% can be acceptable in specific applications.

- Type of Equipment: The choice of machinery, such as impact rollers, vibrating drums, or plate compactors, directly affects the efficiency of compaction.

- Lift Thickness: The thickness of the soil layers being compacted (lifts) plays a vital role in achieving desired density and stability.

- Number of Passes: The number of times the compaction machine passes over a particular area affects the achieved density and is contingent upon the soil type and the compaction degree required.

Understanding these factors is critical for correlating laboratory compaction results with field conditions, thus ensuring the integrity and longevity of construction projects.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Field Compaction

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field compaction control depends on:

(i) Placement water content,

(ii) Type of equipment for compaction

(iii) Lift thickness

(iv) Number of passes based on soil type & degree of compaction desired.

Detailed Explanation

Field compaction is crucial for ensuring the stability and strength of structures built on soil. It depends on four main factors:

1. Placement Water Content: This is the amount of water present in the soil when it is being compacted. The goal is to compact the soil at or close to its optimum moisture content, which is determined through laboratory tests.

2. Type of Equipment for Compaction: Different types of machinery (like rollers, rammers, etc.) can be used for compaction, and each has specific efficiencies and techniques.

3. Lift Thickness: This refers to the thickness of the layer of soil being compacted. Thicker lifts can be more challenging to compact properly.

4. Number of Passes: This means how many times the compaction equipment must pass over the area, which varies based on the soil type and the level of compaction required.

Examples & Analogies

Think of compacting soil like packing a suitcase for a trip. If you have too few items, adding a few more may help fill the suitcase nicely. However, if your clothes are too wet (like soil with too much water), it will be hard to pack them densely. You might need to make multiple attempts (like rolling or folding clothes multiple times) to get everything to fit snugly in the suitcase.

Importance of Optimum Moisture Content

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

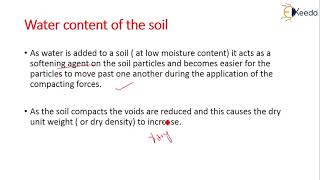

Placement water content is the water content at which the ground is compacted in the field. It is desirable to compact at or close to optimum moisture content achieved in laboratory so as to increase the efficiency of compaction.

Detailed Explanation

The placement water content significantly influences how effectively the soil can be compacted. 'Optimum Moisture Content' (OMC) is the specific water content that allows the most efficient compaction based on laboratory studies. Compaction near this level helps achieve maximum soil density and strength, as it allows particles to bond together effectively. Compaction that's too wet or too dry can lead to weaker soil structures and potential failures.

Examples & Analogies

Imagine baking a cake: if you add too much liquid, the cake will be soggy and won't hold its shape. If there isn't enough liquid, it will be dry and crumbly. Just like baking, soil requires a precise amount of water at the right time (during compaction) to achieve the best results.

Variability in Compaction Practices

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

However, in certain jobs the compaction is done at lower than or higher than OMC (by about 1–2%) depending on the desired function as detailed.

Detailed Explanation

In practical applications, construction jobs might require adjustments to the optimum moisture content based on requirements such as the type of structure being built or the immediate environmental conditions. Sometimes, compaction may be done with water content either slightly below or above the optimum level, typically by 1 to 2 percent. This variability allows engineers to cater to specific project needs while still maintaining sufficient soil integrity.

Examples & Analogies

Think of an athlete preparing for a race. Sometimes they might need to warm up a bit more or do less depending on the weather or the specific demands of the race. Similarly, in construction, soil compaction is adjusted according to the needs of the project.

Key Concepts

-

Placement Water Content: The optimal moisture level to achieve effective soil compaction.

-

Impact Roller: A type of compactor that uses impacts to densify the soil.

-

Vibrating Drum: A device that smoothens surfaces through vibration.

-

Lift Thickness: The measurement of soil depth compacted in a single pass.

-

Number of Passes: Refers to how many times compaction equipment covers the same area.

Examples & Applications

Using a roller with the right water content can significantly improve compaction efficiency.

In high clay content areas, increasing the number of passes may be necessary to achieve adequate density.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For the best compaction, keep the water just right, / Too much or too less puts your efforts in flight.

Stories

Once upon a time, in a land of varying soils, a wise engineer learned that for every type of soil, there existed a perfect amount of water, a perfect lift thickness, and a perfect number of passes to ensure the stability of his kingdom's roads.

Memory Tools

Remember the acronym 'W.L.E.N.': Water, Lift, Equipment, Number of passes for effective compaction!

Acronyms

Use 'PANCEL' to remember

Placement water content

Equipment type

Lift thickness

Number of passes

for effective compaction.

Flash Cards

Glossary

- Placement Water Content

The moisture level of soil at the time of compaction.

- Impact Roller

A compaction tool using static pressure and impact to densify soil.

- Vibrating Drum

A roller drum that provides vibratory motion to level and smooth soil.

- Lift Thickness

The depth of soil being compacted in a single pass.

- Proctor's Needle

A tool used for rapid determination of water content in field soil.

Reference links

Supplementary resources to enhance your learning experience.