Optimal moisture content in compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Compaction Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to explore various methods of soil compaction, including the **Impact Roller**, **Vibrating Drum**, and **Plate & Rammer Compactor**. Can anyone tell me why these machines are important in construction?

They help to make the soil denser, right?

Exactly! These machines reduce the volume of soil, enhancing its load-bearing capacity. The **Impact Roller** uses static pressure combined with impacts, which helps break down soil lumps.

So how does the Vibrating Drum work?

Great question! The Vibrating Drum uses vibratory motion to smoothen ruts and even out the surface. Remember, smoother surfaces are crucial for construction durability.

And what about the Plate Compactor?

The Plate Compactor is fantastic for smaller or hard-to-reach areas, such as backfilling trenches. This variety in tools helps us manage different projects effectively.

Are there any specific situations where we would use each type?

Yes! Each tool has its ideal use case based on the construction needs and the type of soil. Remember, **TIMES**: Type of machine, Intent of use, Material type, Environment, and Soil condition.

To summarize, different compaction methods are critical to ensure that we achieve the desired soil density, especially considering their distinct functionalities.

Understanding Optimal Moisture Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve into the concept of **Optimal Moisture Content**. Can anyone describe what OMC means?

Is it the amount of water we want to have in the soil for proper compaction?

Correct! OMC refers to the moisture level at which soil achieves maximum density when compacted. It's vital for effective field compaction.

Why do we need to compact at or near that moisture level?

When we compact around OMC, we maximize particle interaction and minimize voids. However, sometimes compactions must occur slightly above or below OMC, depending on the project requirements—usually within 1-2%.

What tools can help us determine the moisture content?

Good question! The **Proctor’s Needle** is often used for rapid moisture content determination on site. It gives us immediate feedback on whether we are at optimal levels.

How do we calibrate that needle for accurate results?

Calibration is done using specific soil samples in the lab to create a calibration curve. This is then applied in the field for accurate moisture readings.

To sum it up, achieving optimal moisture content during soil compaction is essential for effective project execution. Remember the key points of OMC: moisture level, density maximization, and the role of equipment!

Factors Affecting Field Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about the factors affecting field compaction. Who can name one of these factors?

The water content, right?

Yes, **placement water content** is a crucial factor. It significantly affects the efficiency of our compaction process. What else can impact compaction?

The equipment we use!

Exactly! Different types of compaction equipment are suited for different soils. Also, we need to consider factors like **lift thickness** and **number of passes** during compaction.

So, more passes mean better compaction?

Generally, yes! But the number of passes is also dependent on soil type and the degree of compaction desired. There’s no one-size-fits-all answer!

What happens if we don’t achieve optimal compaction?

If compaction is not done properly, we risk creating voids in the earth, leading to future ground settlement and structural issues. Thus, applying the correct methods and equipment is critical.

In summary, effective field compaction control hinges on water content, equipment used, lift thickness, and the number of passes. Keep those in mind during your projects!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section highlights key factors influencing field compaction, including placement water content, compaction equipment, lift thickness, and operational parameters. An emphasis is placed on achieving the optimal moisture content for effective compaction results.

Detailed

Detailed Summary

This section focuses on the crucial concept of optimal moisture content (OMC) in soil compaction. It outlines various methods of compaction, such as the Impact Roller, Vibrating Drum, and Plate & Rammer Compactors, each serving different requirements in construction. The section underscores the significance of field compaction control, stressing that success relies on several variables including placement water content, the type of equipment used, the thickness of lifts, and the number of passes needed depending on soil type. Furthermore, it explains the necessity to compact at or near the laboratory-determined OMC to maximize efficiency, although adjustments may be necessary in some scenarios. Key techniques such as Proctor’s Needle for rapid field water content determination are also introduced, culminating in a comprehensive understanding of how these factors intersect to affect soil densification.

Youtube Videos

![Optimum Moisture (Water) Content [OMC] | Geotechnical Engineering | Civil Engineering Shorts](https://img.youtube.com/vi/ntvKuLvIG6g/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Placement Water Content

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

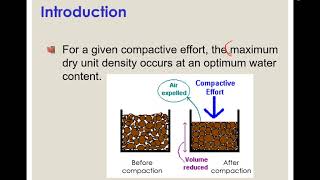

Placement water content is the water content at which the ground is compacted in the field.

Detailed Explanation

Placement water content is significant because it determines how well soil can be compacted. If the water content is too high or too low, the soil may not achieve the desired density and stability. Optimal water content allows soil particles to move and align closely, enhancing compaction.

Examples & Analogies

Think of making a sandcastle. If you use dry sand, it breaks apart easily. If you use too much water, it becomes too wet and loses shape. The perfect balance allows the sandcastle to stand firm, similar to how soil needs optimal moisture for effective compaction.

Compaction Efficiency and Optimum Moisture Content (OMC)

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

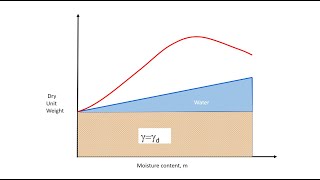

It is desirable to compact at or close to optimum moisture content achieved in laboratory so as to increase the efficiency of compaction.

Detailed Explanation

Compacting soil at its optimum moisture content (OMC) as determined by laboratory tests ensures maximum density and stability. This optimal condition helps the soil particles to interlock more efficiently, reducing air gaps and increasing load-bearing capacity.

Examples & Analogies

Imagine trying to compress a sponge. If the sponge is too dry, it won't compress well. If it's too wet, it might squish instead of compress. But when it’s damp enough, you can compress it effectively to make it denser, just like soil at OMC.

Adjustment of Water Content for Specific Jobs

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

However, in certain jobs the compaction is done at lower than or higher than OMC (by about 1–2 %) depending on the desired function.

Detailed Explanation

In some construction situations, soil compaction might require a slight deviation from the optimum moisture content, whether higher or lower. This adjustment is necessary to achieve specific structural requirements or to account for environmental conditions that affect soil behavior.

Examples & Analogies

Consider baking a cake. If the recipe calls for just the right amount of flour, that’s like using OMC for soil. But sometimes, you might need to add a bit more or less flour to get the desired texture. Similarly, adjusting moisture content ensures the soil meets specific project needs.

Field Compaction Control Factors

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field compaction control depends on (i) Placement water content, (ii) Type of equipment for compaction (iii) Lift thickness (iv) Number of passes based on soil type & degree of compaction desired.

Detailed Explanation

Effective control of field compaction relies on several factors: the moisture content of the soil being compacted, the type of machinery used, how thick each layer of soil is (lift thickness), and how many times the machinery passes over the soil. Each of these elements plays a critical role in achieving the desired density and stability.

Examples & Analogies

Imagine leveling a lawn. You need the right amount of water (moisture), the right tools (like a roller or compactor), a proper layer thickness of soil, and you have to go over the area enough times to ensure it's flattened evenly. Each step affects the final result, just like in soil compaction.

Key Concepts

-

Impact Roller: A machine that combines static pressure and impact for soil compaction.

-

Placement Water Content: The specific amount of water present in soil during compaction.

-

Lift Thickness: The vertical depth of soil that is compacted in a single operation.

-

Proctor’s Needle: A tool for measuring moisture content quickly in the field.

Examples & Applications

Using an Impact Roller on a large construction site to achieve high-density soil.

Utilizing a Plate Compactor in a confined area, such as a trench, for effective backfilling.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For moisture that's right but not too tight, compacting soil is a sight!

Stories

Once upon a time, a construction site called 'Compaction Valley' learned that soil needed the 'just right' water level to get firm and strong. OMC became their magic word!

Memory Tools

To remember the factors affecting field compaction, think W.E.L.P.: Water content, Equipment, Lift thickness, Passes.

Acronyms

For compacting success, remember **C.W.L.P.**

Compaction

Water content

Lift thickness

Passes.

Flash Cards

Glossary

- Optimal Moisture Content (OMC)

The moisture level at which soil achieves maximum density when compacted.

- Proctor’s Needle

An instrument used for rapid determination of soil moisture content in the field.

- Compaction

The process of densifying soil by reducing voids through mechanical means.

- Lift Thickness

The thickness of the soil layer that is compacted in a single pass.

- Impact Roller

A compaction device that combines static pressure with impact to densify soil.

Reference links

Supplementary resources to enhance your learning experience.