Type of equipment for compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Impact Roller

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are examining the impact roller. Can anyone tell me what makes it special?

It uses static pressure and impacts to compact soil, right?

Exactly! The impact roller combines these forces, and it's effective at breaking soil lumps and kneading the soil. Remember, think of 'pressure plus impact'—let's call it PI for easy recall.

So, it really helps with leveling and creating a stable surface!

Yes, well said! What might be an example of when we would use an impact roller?

Maybe in large construction sites where the soil is uneven?

Precisely! Great connection, let's summarize: Impact rollers compress soil using pressure and impact, leading to a stable surface.

Vibrating Drum

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's dive into the vibrating drum. Can someone explain what it does?

It smooths out the soil, right? It vibrates!

Correct! The vibratory motion levels and smoothens ruts effectively. Remember 'Vibrating for Victory'—it advances our compaction goals.

What types of jobs would require a vibrating drum?

Excellent question! It’s often used on roadways and large surfaces where a smooth finish is crucial. Can you think of any other situations?

Maybe when laying down a new parking lot?

Absolutely! Remember the vibrating drum is all about achieving a well-leveled surface for better durability. Let’s wrap up this segment!

Plate & Rammer Compactor

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s look at the plate and rammer compactor. What is its primary application?

It's for small projects like trenches, right?

Exactly! Ideal in compact spaces and less accessible areas. Think of 'Compact Small, Work Smart!' - that's a good way to remember its utility.

What makes it efficient for smaller areas?

Good point! The compactors generate a significant amount of force easily handled in tighter spaces. Also, how do we ensure effective compaction in such areas?

Using the right water content?

Correct! Proper water content is critical for effective compaction. Let’s recap: Plate and rammer compactors are perfect for small, confined jobs!

Field Compaction Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about compaction control in the field. What factors do you think play a crucial role?

Placement water content and type of equipment, maybe?

Exactly! We consider placement water content, type of equipment, lift thickness, and the number of passes. Let’s create an acronym: 'P-E-L-N' for Placement, Equipment, Lift thickness, and Number of passes.

That’s a good way to remember! What’s the importance of optimum moisture content?

Great question! It ensures efficient compaction, typically around the optimum moisture level found in laboratory tests. What can happen if we deviate too much from this range?

It could lead to poor compaction results!

Exactly! Remember, optimal compaction depends on controlling these variables effectively.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section highlights key equipment used in compaction processes, emphasizing their specific roles such as compacting, leveling, and kneading soil. Also covered are factors impacting field compaction control, including water content and lift thickness.

Detailed

Type of Equipment for Compaction

This section outlines the essential types of equipment used for compaction, providing insights into their unique functionalities and applications in construction.

Equipment Types

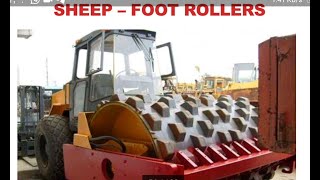

- Impact Roller: Utilizes static pressure combined with the impact of a pentagonal roller to achieve compaction. The high impact energy breaks soil lumps and enables a kneading action, making it effective for achieving a dense, stable surface.

- Vibrating Drum: Equipped with a vibratory motion, this roller helps level and smoothen ruts in the soil, improving the quality of compacted surfaces.

- Plate & Rammer Compactor: Ideal for backfilling trenches, small constructions, and less accessible locations, this equipment generates significant force to compact soil effectively.

Importance of Compaction Control

Field compaction control is crucial to achieving desired compaction levels. Key factors affecting field compaction include:

- Placement water content: It is vital to compact at or near the optimum moisture content for efficient results. Deviations of about 1-2% from the optimum may occur based on job requirements.

- Type of equipment used for compaction.

- Lift thickness: The thickness of material placed before compaction.

- Number of passes: Varies based on soil type and the degree of compaction desired.

Understanding these core concepts is essential for determining effective compaction practices in the field.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Impact Roller

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Compaction by static pressure combined with impact of pentagonal roller.

- Higher impact energy breaks soil lump and provides kneading action.

Detailed Explanation

The Impact Roller uses a combination of static pressure and the dynamic impact of a pentagonal-shaped roller to compact soil. The static pressure pushes down on the soil while the impacts from the roller break up soil lumps, allowing for a kneading action that helps in densifying the soil.

This kneading action is essential because it helps to achieve a uniform density by mixing the soil particles effectively. The pentagonal shape of the roller also plays a role in how the impacts are delivered to the soil.

Examples & Analogies

Think of the Impact Roller like a chef kneading dough. Just as the chef uses their hands to press down and fold the dough to blend ingredients and create a smooth texture, the roller applies static pressure while impacting the soil, mixing it to create a denser, more solid foundation.

Vibrating Drum

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Roller drum fitted with vibratory motion.

- Levels and smoothens ruts.

Detailed Explanation

The Vibrating Drum is equipped with a mechanism that creates vibratory motion as it rolls over the ground. This vibration helps to level and smoothen out any ruts or uneven areas in the soil. The shaking motion helps to compact the soil more thoroughly compared to static methods alone, as it causes the particles to move closer together.

Examples & Analogies

Imagine a washing machine that vibrates to help clean clothes. Just like the vibratory action of the washing machine helps to shake dirt out of clothes, the vibrating drum shakes the soil particles closer together, ensuring a more compact and stable surface.

Plate & Rammer Compactor

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

It is used for backfilling trenches, smaller constructions and less accessible locations.

Detailed Explanation

The Plate & Rammer Compactor is a simpler, smaller equipment used for compacting soil, especially in tight or confined areas such as trenches or during minor construction projects. It operates by using a flat, heavy plate or a rammer that pounds the ground repeatedly to compact the soil effectively. This tool is ideal for smaller volumes of soil and helps to ensure that dust or gravel remains stable and does not settle over time.

Examples & Analogies

Think of the Plate & Rammer Compactor like a toddler jumping on a pillow to flatten it. The child’s repeated jumps (similar to the impact from the compactor) compress the pillow, flattening it and making it more compact. In construction, this ensures that the earth beneath a building or path is solid and secure.

Key Concepts

-

Impact Roller: Utilizes pressure and impact to compact soil.

-

Vibrating Drum: Smoothens and levels soil surfaces with vibratory motion.

-

Plate Compactor: Suitable for small jobs and tight spaces.

-

Field Compaction Control: Involves managing factors like water content and lift thickness.

Examples & Applications

Impact rollers are often used in road construction where dense material layers are needed.

Vibrating drums are utilized in preparing surfaces for asphalt paving, ensuring a smoother finish.

Plate compactors are ideal for backfilling small trenches in residential areas.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For compact soil that's tough and true, an impact roller will do for you!

Stories

Once upon a time, a construction team faced uneven ground. They summoned the impact roller to break tough lumps and smooth over the land, making way for a magnificent road.

Memory Tools

To remember 'Placement, Equipment, Lift thickness, Number of passes', think: 'Plenty of Elephants Lift Nicely'.

Acronyms

PEL-N

Placement water content

Equipment type

Lift thickness

Number of passes.

Flash Cards

Glossary

- Impact Roller

A type of compaction equipment that uses static pressure combined with impact forces to break soil lumps and knead the material.

- Vibrating Drum

A roller drum fitted with a vibratory mechanism to compact and smoothen the soil surface.

- Plate Compactor

A compacting device primarily used for backfilling trenches, small constructions, and tight spaces.

- Lift Thickness

The depth of soil placed before compaction, impacting effectiveness.

- Placement Water Content

The moisture level present in soil at which compaction is conducted.

Reference links

Supplementary resources to enhance your learning experience.