Compaction control in field

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Compaction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing the factors that influence soil compaction in the field. Can anyone name a key factor we should consider?

Is it the water content?

Exactly! The placement water content is crucial for effective compaction. When we compact soil, we ideally want to do so at the optimum moisture content, similar to what we determine in the lab. Why do you think that is, Student_2?

Because it ensures the soil particles are well-arranged?

Correct! Proper moisture helps break down soil lumps and allows for better arrangement. Let’s remember this with the acronym 'PMO' which stands for Placement, Moisture, and Optimization. Can anyone think of examples when this might not hold true?

Maybe when the weather is different?

Yes, in certain cases, we might compact at different moisture levels, either lower or higher by 1-2%. Great observation! Let’s summarize: Effective field compaction relies heavily on correct placement water content to optimize the process.

Equipment Types and Their Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss various types of compaction equipment. Who can explain the purpose of an impact roller?

It uses static pressure and impact to compact soil!

Correct! The impact roller uses high energy to break soil lumps. Can anyone tell me about another compaction method?

There’s the vibrating drum, right?

Right again! The vibrating drum helps level and smoothen cold ruts in the surface. Good job! Can everyone remember the impact roller with the phrase 'crush and knead'? Let’s say it together!

Crush and knead!

Great! This means that effective compaction can also depend on the equipment you choose.

Field Compaction Control Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've discussed equipment, let’s look into some techniques to control compaction in the field. What’s another important factor we haven’t discussed yet?

Lift thickness?

Yes! Lift thickness is crucial. Thicker layers may not compact effectively. Can anyone think about why that could be problematic?

Because the machine may not penetrate through the tough top layer?

Exactly! If the lift is too thick, the underlying layers might remain loose. It's also essential to consider the number of passes. Who can explain why this matters?

More passes might lead to better compaction, right?

Correct! More passes apply more pressure, leading to denser soil. Let’s summarize this session: Effective compaction involves managing lift thickness and the number of passes to achieve desired results.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Understanding how to control compaction in the field is vital for soil stability and construction quality. Key factors influencing compaction include placement water content, equipment type, lift thickness, and the number of passes. This section also highlights various compaction methods like the impact roller, vibrating drum, and plate & rammer compactor.

Detailed

Compaction Control in Field

Compaction control in the field is crucial for ensuring soil stability and the quality of construction projects. Several factors influence the efficiency of field compaction:

- Placement Water Content: The optimal moisture content achieved in the laboratory should be maintained for effective compaction. Deviations may occur based on project requirements.

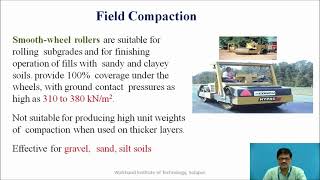

- Type of Equipment: Different compaction tools, like impact rollers and vibrating drums, serve varied purposes and efficiencies in soil densification.

- Lift Thickness: The thickness of the soil layer being compacted can affect overall compaction effectiveness.

- Number of Passes: The number of times the equipment passes over the soil depends on its type and the desired degree of compaction.

Additionally, tools such as Proctor’s Needle facilitate rapid determination of water content, indicating how moisture levels can be optimized during compaction processes.

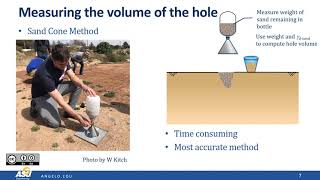

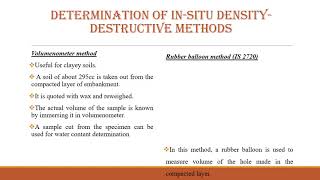

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Factors Affecting Field Compaction

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field compaction control depends on:

(i) Placement water content,

(ii) Type of equipment for compaction,

(iii) Lift thickness,

(iv) Number of passes based on soil type & degree of compaction desired.

Detailed Explanation

Field compaction control is determined by several crucial factors. The placement water content refers to the amount of water in the soil when it is compacted. It is important to use the right type of equipment suitable for the compaction task, and the thickness of each layer (or lift) of soil also plays a vital role in the process. Lastly, the number of passes of the compaction equipment affects the density of the soil and is often adjusted based on the soil type and the required degree of compaction.

Examples & Analogies

Think of making a perfect cake. You need to use the right amount of flour (placement water content), the right mixing tool (type of equipment), the right size of cake layers (lift thickness), and mixing it just enough times (number of passes) to get the best texture. If any step is off, your cake won’t turn out as perfectly as you’d like!

Importance of Optimum Moisture Content

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Placement water content is the water content at which the ground is compacted in the field. It is desirable to compact at or close to optimum moisture content achieved in laboratory so as to increase the efficiency of compaction. However, in certain jobs the compaction is done at lower than or higher than OMC (by about 1–2%) depending on the desired function.

Detailed Explanation

The placement water content during compaction is crucial as it directly relates to the efficiency of the process. Compaction is most effective when the soil’s moisture level is close to what is known as optimum moisture content (OMC), which is determined in laboratory conditions. Sometimes, for specific projects, compaction at slightly lower or higher water levels (by 1-2%) may be necessary to achieve the intended results or functionalities.

Examples & Analogies

Imagine filling a balloon with water. If the water level is just right, the balloon expands perfectly. If there’s too much or too little water, the balloon might not inflate properly or could burst. Similarly, soil needs the correct amount of moisture to compact effectively.

Variables in Vibratory Compaction

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

There are many variables which control the vibratory compaction or densification of soils.

Detailed Explanation

Vibratory compaction involves using vibrations to help settle soil particles closer together, which increases the density of the soil. Various factors can influence this process, including the frequency and amplitude of vibrations, the type of soil, and environmental conditions. Understanding these variables is essential to achieve optimal compaction in the field.

Examples & Analogies

Consider a crowded concert where people are packed tightly. If the crowd is jumping up and down (similar to vibrations), they naturally get closer together. If there are too few people or not enough jumping, the crowd might remain loose. Just like in soil compaction, the right conditions must be met to achieve the desired density.

Key Concepts

-

Placement Water Content: Deciding the optimal moisture content for compaction.

-

Equipments: Different types of rollers and compactors serve distinct purposes.

-

Lift Thickness: The thickness of the layer affects the quality of compaction.

-

Number of Passes: More passes often lead to better density and stability.

Examples & Applications

Using an impact roller to break large lumps of soil during initial phases of compaction.

Employing a vibrating drum to level a surface for a new walkway.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To compact soil, moisture needs to flow, keeping the structure healthy for all to grow.

Stories

Imagine a construction site where workers use different rollers - each roller representing a different force that either kneads or flattens the soil, ensuring a solid foundation for a future skyscraper.

Memory Tools

Remember 'PLANT' for effective ground control: Placement, Lift, Amount of passes, Number of equipment types, and Type of moisture.

Acronyms

WCM for Water Content Management in smooth soil structuring.

Flash Cards

Glossary

- Compaction

The process of densifying soil to improve its load-bearing capacity.

- Placement Water Content

The water content of soil at which it is compacted during field operations.

- Impact Roller

A type of roller that combines static pressure and impact motion to compact soil.

- Lift Thickness

The thickness of the soil layer being compacted.

- Proctor’s Needle

A device used for the rapid determination of water content in soil.

Reference links

Supplementary resources to enhance your learning experience.