Field Compaction Control

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Placement Water Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about placement water content, which is critical for effective soil compaction. Can anyone tell me what it refers to?

Isn't it the amount of water in the soil when we're compacting it?

Exactly! Placement water content is essentially the moisture level at which we compact the ground. It's best to keep it close to the optimum moisture content, achieved in the lab, for the most efficient compaction. Remember: 'Moisture Matters!' to enhance soil density.

What happens if we compact it at higher or lower moisture levels?

Good question! Compaction at levels higher or lower than OMC can lead to less effective thickening or other issues. It's about finding the right balance.

Type of Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to the type of equipment used for compaction. What kinds of equipment can you name?

There's a roller, right? Like a vibrating drum?

And there's the impact roller as well!

Correct! The impact roller uses static pressure and impact energy to break soil lumps and knead the ground. Vibrating drums, on the other hand, help level and smooth out any irregularities. Remember: 'Different Tools, Different Rules!'

Does it make a difference for different soil types?

Absolutely! Certain equipment works better for sandy soils, while others perform optimal compaction in clay. Knowing the type of soil is key to choosing the right tool.

Lift Thickness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss lift thickness. Who can explain what that means?

Is it how thick the layer of soil we compact is?

Correct! Lift thickness is crucial because if it's too thick, the lower layers won't compact properly. Remember: 'Thin Layers, Great Densities!' It’s often recommended to keep lifts around 6 to 8 inches.

So, smaller lifts might be better?

Exactly! Smaller lifts tend to provide better compaction results and should be based on the type of equipment used as well.

Number of Passes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Our last topic is the number of passes needed for compaction. Who can summarize why this might change?

I think it depends on the soil type and how compact we want it to be?

Exactly! For example, clay soils often require more passes compared to sandy soils because they compact differently. Key takeaway: 'Pass More on Clay!' It’s all about adapting to the soil’s characteristics.

So we might need to adjust our plans based on the results?

Right! Always monitor your compaction and adjust if necessary. It ensures the best results for your projects.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the critical factors affecting field compaction control, particularly placement water content, the equipment used for compaction, lift thickness, and the number of passes based on soil type and required compaction. It underscores the importance of aligning field conditions with laboratory specifications for optimal results.

Detailed

Field Compaction Control

Compaction in the field is crucial to achieving the desired soil density and stability for construction projects. This process is influenced by several key factors:

- Placement Water Content: This is the water content at which soil is compacted. Maximizing compaction efficiency generally requires moist soil—ideally near the optimum moisture content (OMC) established in laboratory conditions.

- Type of Equipment: The choice of equipment, such as vibratory rollers, impact rollers, and plate compactors, significantly affects the compaction process. Each type offers different methods and efficiencies for densifying various soil types.

- Lift Thickness: The thickness of the soil layer being compacted, known as lift thickness, plays a crucial role. Thicker lifts may lead to insufficient compaction as deeper layers may not achieve the necessary density.

- Number of Passes: The number of compaction passes required will vary depending on the type of soil and the degree of compaction needed. It is important to adjust the number of passes based on the specific conditions and goals of the project.

Understanding these aspects is essential for engineers and technicians to ensure effective compaction and enhance the performance of structures built on compacted soil.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Field Compaction Control

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

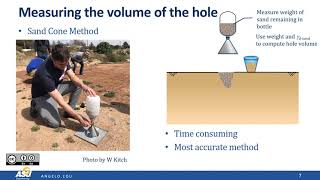

It is extremely important to understand the factors affecting compaction in the field and to estimate the correlation between laboratory and field compaction.

Detailed Explanation

Understanding field compaction control is crucial for ensuring that soil in construction or landscaping projects is properly compacted. Compaction affects the stability and strength of the soil, which in turn impacts the durability of structures. Additionally, being able to correlate laboratory results with field results helps engineers and construction professionals predict how the soil will react on-site.

Examples & Analogies

Imagine baking a cake where you want to ensure a sturdy structure. If the ingredients (like flour and sugar) are not mixed properly (akin to soil being compacted) and the temperature is off (similar to field conditions), the cake may not rise or hold its shape—leading to a collapse. Similarly, proper compaction ensures that structures stand strong.

Factors Affecting Field Compaction

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field compaction control depends on (i) Placement water content, (ii) Type of equipment for compaction, (iii) Lift thickness, (iv) Number of passes based on soil type & degree of compaction desired.

Detailed Explanation

There are several essential factors that influence how well compaction occurs in the field:

1. Placement Water Content: The ideal moisture content of the soil makes it easier to compact.

2. Type of Equipment: Different compaction equipment (like rollers or rammers) work best on different types of soil.

3. Lift Thickness: This is how thick the layer of soil is that you’re compacting—thinner layers compact more effectively.

4. Number of Passes: More passes may be needed based on the soil type and the compaction needed, meaning how dense you want the soil to be after compaction.

Examples & Analogies

Think of a sponge soaked with water. If you try to squeeze it out, it won't lose its shape if it's too wet, and it won't compact. This is like how the placement water content affects compaction. Different sponges (different soil types) require different squeezing techniques (equipment) to ensure they are compacted correctly.

Optimum Moisture Content (OMC)

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Placement water content is the water content at which the ground is compacted in the field. It is desirable to compact at or close to optimum moisture content achieved in laboratory so as to increase the efficiency of compaction. However, in certain jobs the compaction is done at lower than or higher than OMC (by about 1– 2 %) depending on the desired function as detailed.

Detailed Explanation

Optimum Moisture Content (OMC) is the specific moisture level at which soil achieves the maximum density when compacted. Compaction near this moisture level enhances the efficiency of the process, making the soil denser and preventing future settling. However, based on the specific needs of a project, sometimes compaction may occur at slightly wet or dry conditions (1-2% deviation) to achieve desired results.

Examples & Analogies

Consider a sponge again. If you’re aiming for a perfect compacted sponge to fit in a tight container, using it when it's just the right amount of damp (OMC) will take up the least space. If it's too wet, it won’t fit; if it's too dry, it won’t be compacted well. Knowing how wet or dry is ideal helps achieve the best result.

Key Concepts

-

Placement water content: The moisture content at which soil is compacted.

-

Equipment Type: Different compaction tools serve varied purposes.

-

Lift thickness: Thickness of soil layers can greatly affect compaction efficacy.

-

Number of passes: The required frequency of passes depends on soil type and density desired.

Examples & Applications

Using a vibratory roller on clay soil requires more passes than on sandy soil for effective compaction.

Compacting soil at 1-2% below OMC can still yield good results for certain projects.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When you compact, keep water in sight, for better soil, make it just right!

Stories

Imagine a builder preparing a site. He knows that too much water will make his soils tight. He remembers to check the moisture levels and chooses his equipment with great care, ensuring that when it's compacted, it'll be good and rare.

Memory Tools

Remember C.E.L.N for compaction: C for Content, E for Equipment, L for Lift thickness, N for Number of passes.

Acronyms

W.E.L.L. - Water, Equipment, Lift thickness, and Layers.

Flash Cards

Glossary

- Placement Water Content

The moisture content at which soil is compacted during field operations.

- Optimum Moisture Content (OMC)

The ideal moisture level at which soil can achieve maximum density during compaction.

- Lift Thickness

The thickness of the soil layer being compacted.

- Number of Passes

The number of times compaction equipment drives over the same area to achieve desired density.

- Vibratory Roller

A compaction machine that uses vibration to improve soil density.

- Impact Roller

Compaction equipment that combines static pressure with the impact force to compact soil.

Reference links

Supplementary resources to enhance your learning experience.