Importance of understanding factors affecting compaction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Placement Water Content

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's start with the importance of placement water content. Can anyone tell me what this means?

Is it how much moisture is in the soil when we're compacting it?

Exactly! The placement water content is crucial for maximizing compaction efficiency. Ideally, we want to be close to the Optimum Moisture Content, or OMC, which we determine in the lab. Do you know why this is important?

Because it ensures the soil particles are able to move around and settle into a denser formation?

Very good! This helps in breaking soil lumps and achieving better density. Just remember, too much or too little moisture can prevent proper compaction. Let's think of a mnemonic: 'WET - Water Enables Tightening' to recall the significance of adequate water content during compaction.

So if we have to add or remove water, how much can we adjust from the OMC?

Excellent question! Typically, adjustments can be made by plus or minus 1-2%. This flexibility is critical depending on the job at hand.

Type of Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move on to the type of equipment used for compaction. Can someone share what types they have come across?

I've heard about vibratory rollers and plate compactors.

Right! Each type of equipment has its unique advantages depending on soil conditions and project needs. For example, vibratory rollers are effective because they use vibration to assist in soil compaction. Can anyone mention a situation where you would choose a smaller compaction device?

For trenches or tight spaces, like when backfilling!

Correct! In those cases, a plate or rammer compactor is ideal. Remember, the key is matching the equipment with both the project conditions and soil type for effective results. Let’s use the acronym: “CREATED - Choice of Roller Equipment Achieves Targeted Effective Densification

Lift Thickness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss lift thickness. Why do you think this aspect matters during compaction?

I assume it impacts how dense the soil gets, right?

Exactly! Lift thickness relates to the layers of soil being compacted. Thicker lifts may not compact uniformly, leading to inconsistencies. As a guideline, lifts should typically be limited to about 6 to 12 inches. Can anyone suggest why keeping it thin might be better?

Because thinner lifts allow for more uniform compaction across the entire area!

Right again! Keeping lifts thinner helps achieve a more uniform density, which is essential for stability. Let's remember: 'One Layer, One Love' when thinking about lift thickness.

Number of Passes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, we need to look at the number of passes during compaction. Why do you think this is important?

More passes should lead to better compaction, right?

Yes! More passes can help achieve greater density, but it also depends on the soil type. Can anyone give an example of a soil type that might need more passes?

Clay soils probably need more passes due to their density and binding nature!

Great example! Remember, whenever you're working with denser soils, expect to give it that extra effort with more passes. Let's use a little rhyme: “Pass on the Clay, Compact All Day!” to recall this.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the importance of comprehending various factors that influence soil compaction in the field. It covers the role of water content, equipment type, lift thickness, and the number of passes required for effective compaction.

Detailed

Importance of Understanding Factors Affecting Compaction

Compaction is a critical aspect of construction that ensures the stability and durability of structures. Understanding the factors affecting compaction is essential to correlate laboratory results with field conditions.

Key Factors Influencing Field Compaction

- Placement Water Content: This refers to the moisture level at which soil is compacted in the field. It is advisable to achieve compaction close to the Optimum Moisture Content (OMC) derived in the lab to ensure efficiency. However, depending on specific project requirements, moistening may occur either above or below the OMC by approximately 1-2%.

- Type of Equipment: Different equipment affects compaction efficacy and must be chosen based on specific soil types and conditions.

- Lift Thickness: Refers to the thickness of soil layers during placement, which impacts density and overall compaction.

- Number of Passes: The number and type of passes made by compaction equipment depend on the soil type and the desired degree of compaction. Proper understanding of these factors is vital for optimal results.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Field Compaction Control

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Field compaction control depends on (i) Placement water content, (ii) Type of equipment for compaction, (iii) Lift thickness, (iv) Number of passes based on soil type & degree of compaction desired.

Detailed Explanation

This chunk explains the critical components that affect compaction in the field. Field compaction control involves understanding four main factors:

1. Placement Water Content: This refers to the moisture level at which soil will be compacted. Proper water content is essential for effective compaction.

2. Type of Equipment for Compaction: Different machines are designed based on the type of soil and the specific job needs. For instance, vibratory compactors are often used for granular soils, while static rollers work better with cohesive soil.

3. Lift Thickness: This is the depth of the soil layer that is being compacted. Each lift must be compacted properly before more soil is added.

4. Number of Passes: Each pass of the compactor adds a layer of density to the soil. Depending on the soil type and the required level of compaction, the number of passes will vary.

Examples & Analogies

Imagine a sponge soaked with water. If you press it gently, you can remove some water, and it will stay somewhat intact (like the soil at optimal moisture). However, if you squeeze too hard or not enough, the sponge will either break apart (too much compaction) or won't be compact enough to hold form (not enough compaction). This analogy helps us understand how balancing water content, equipment, lift thickness, and passes can result in optimal soil compaction.

Placement Water Content

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

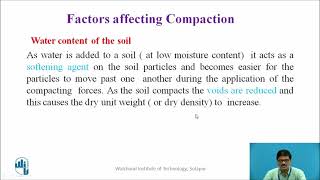

Chapter Content

Placement water content is the water content at which the ground is compacted in the field. It is desirable to compact at or close to optimum moisture content achieved in laboratory so as to increase the efficiency of compaction.

Detailed Explanation

This section emphasizes the significance of placement water content in the compaction process. The placement water content is the specific moisture level where the soil is most effectively compacted. Achieving this level is ideal because it aligns with the 'optimum moisture content' (OMC) determined in laboratory tests. When soil is compacted near this optimum level, it becomes denser and more stable, contributing to better structural integrity. Compacting soil too dry or too wet can lead to ineffective compaction and thus poor quality ground.

Examples & Analogies

Think of baking bread. If you add too much water to the dough, it becomes soupy and won't rise well (like wet soil that can't be compacted). If you don’t add enough water, the dough will be too dry to form correctly. For the best results, you need the right amount of moisture. Similarly, achieving the correct placement water content in soil compaction ensures that the soil can support the weight and function it’s meant to.

Adjusting for Different Conditions

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

However, in certain jobs the compaction is done at lower than or higher than OMC (by about 1– 2 %) depending on the desired function as detailed.

Detailed Explanation

This chunk discusses the flexibility required in compaction practices. While the ideal scenario is to compact at optimum moisture content, there are jobs where slight adjustments may be necessary. In some cases, soil may need to be compacted at a water content lower or higher than 1-2% of the optimum moisture depending on the project requirements. For example, if a quick setup is needed for temporary structures, slightly under-compacted soil may be sufficient until more permanent solutions can be applied. Understanding when and how to adjust moisture levels is crucial in ensuring the soil meets the specific needs of a project.

Examples & Analogies

Consider a sports team that usually plays best on a dry, firm field but occasionally has to play on a muddy one due to weather conditions. They might adjust their strategy or tactics to perform well even in less-than-ideal situations. Similarly, adjusting the water content for soil compaction ensures that projects can move forward successfully, regardless of less-than-optimal soil conditions.

Key Concepts

-

Placement Water Content: The moisture level that optimizes soil compaction.

-

Optimum Moisture Content (OMC): The ideal moisture content for maximum density.

-

Lift Thickness: Affects uniformity in compaction based on its thickness.

-

Number of Passes: Influences density achieved based on equipment and soil type.

Examples & Applications

A construction site uses vibratory rollers to compact sandy soils due to their granular nature.

During a trench backfill project, a plate compactor is employed to navigate limited space.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Water in the soil helps it settle in a role, compacting down to make it whole.

Stories

Imagine a builder at a construction site, adjusting the water levels, layer by layer. He remembers to keep it light with lifts that are tight, ensuring the soil is packed just right.

Memory Tools

Use 'WET' (Water Enables Tightening) to recall the importance of placement water content.

Acronyms

“CREATED” - Choice of Roller Equipment Achieves Targeted Effective Densification.

Flash Cards

Glossary

- Compaction

The process of increasing the density of soil by reducing air voids through mechanical means.

- Placement Water Content

The optimal moisture level at which soil is compacted in the field.

- Optimum Moisture Content (OMC)

The moisture content at which soil achieves maximum density when compacted.

- Lift Thickness

The thickness of the layer of soil being compacted.

- Number of Passes

The number of times compaction equipment passes over the soil to ensure adequate density.

Reference links

Supplementary resources to enhance your learning experience.