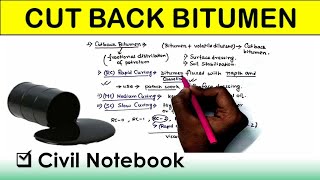

Cutback Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Cutback Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are diving into the world of cutback bitumen. Can anyone tell me what cutback bitumen is?

Isn't it a type of bitumen that’s mixed with solvents?

Exactly! Cutback bitumen is produced by blending bitumen with volatile solvents such as kerosene or naphtha. This process helps in reducing the viscosity of the bitumen.

So, what is the advantage of reducing viscosity?

Great question! Reducing viscosity allows cutback bitumen to be fluid at much lower temperatures, which is crucial for applications like surface dressing, especially in cold weather conditions.

Can you explain more about how it's used in surface dressing?

Certainly! Cutback bitumen is particularly effective in surface treatments where a rapid application is required, making it easy to work with even in cooler environments.

To remember the key points, think of the acronym 'COLD' – Cutback, Oil-based, Lower temperature, Dressing applications. Let’s summarize: cutback bitumen is a blend of bitumen and solvents that makes it suitable for cold weather applications.

Properties of Cutback Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What properties do you think cutback bitumen offers that are different from regular bitumen?

I guess it flows better in cold temperatures?

Correct! Its low viscosity at lower temperatures allows it to flow easily and be applied in various conditions. Additionally, it enhances workability.

Are there any downsides to using cutback bitumen?

A good point! While it has advantages, cutback bitumen can be less durable compared to other types over time. Also, environmental concerns regarding VOC emissions from the solvents can arise.

So, it seems there are trade-offs?

Yes, that's right! It’s all about balancing ease of use and environmental impact. In summary, cutback bitumen is notable for its low-temperature flow and applicability in surface dressing but comes with durability considerations.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Cutback bitumen is a type of bitumen that is achieved by mixing bitumen with volatile solvents such as kerosene or naphtha, which reduces its viscosity. This modification allows for easier application in surface dressing and is particularly useful in colder temperatures where traditional bitumen would be too viscous.

Detailed

Cutback Bitumen

Cutback bitumen is a specialized form of bitumen that is created by the incorporation of volatile solvents, such as kerosene or naphtha. The primary purpose of this blending is to decrease the viscosity of the bitumen, enabling it to remain fluid at much lower temperatures compared to standard bitumen. This characteristic becomes particularly advantageous during its application for surface dressing and other cold weather applications. The process of creating cutback bitumen makes it easier to work with and apply, thereby enhancing its usability across various engineering scenarios, especially where lower temperatures could hinder the effectiveness of traditional bitumen.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Cutback Bitumen

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Made by blending bitumen with a volatile solvent (like kerosene or naphtha).

Detailed Explanation

Cutback bitumen is a type of bitumen that is created by mixing standard bitumen with a volatile solvent. This solvent helps reduce the thickness of the bitumen, making it easier to handle and apply. Some common solvents include kerosene and naphtha, which evaporate quickly as the bitumen is applied.

Examples & Analogies

Think of making a smoothie. Just like you blend fruit with some liquid (like juice) to make it easy to drink, cutback bitumen is made liquid by adding solvents so it can be easily applied to road surfaces.

Properties of Cutback Bitumen

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Becomes fluid at lower temperatures.

Detailed Explanation

One of the significant properties of cutback bitumen is its ability to become fluid at lower temperatures compared to regular bitumen. This is crucial, especially in colder climates. When cutback bitumen is mixed with a solvent, it lowers the viscosity, meaning it flows better and can be worked with more easily.

Examples & Analogies

Imagine how honey behaves in different temperatures. When it's warm, honey flows easily, but when it's cold, it becomes thick and hard to pour. Similarly, cutback bitumen flows easily at lower temperatures, making it more user-friendly in various weather conditions.

Uses of Cutback Bitumen

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Used in surface dressing and cold weather applications.

Detailed Explanation

Cutback bitumen is particularly useful in applications like surface dressing, where it is used to seal and protect the road surface. It's also essential for cold weather applications because its properties allow for better adhesion and application, even when conditions are not ideal for traditional bitumen.

Examples & Analogies

Think about putting on a jacket when it’s chilly outside. Just like a jacket keeps you warm and makes you comfortable in cold weather, cutback bitumen helps maintain the quality of roads during less favorable conditions, offering a reliable solution for road maintenance and construction.

Key Concepts

-

Cutback Bitumen: A blend of bitumen with volatile solvents used to lower viscosity.

-

Viscosity Reduction: Makes bitumen fluid at lower temperatures for easier application.

-

Cold Weather Application: Suitable for use in surface dressing and other cold weather conditions.

Examples & Applications

Cutback bitumen is often used in surface treatments of roads in colder regions where regular bitumen would be too thick to work with.

For cold weather paving, cutback bitumen mixes provide better flexibility and application efficiency.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cutback flows with ease, even in the chill, applying it on roads gives workers a thrill.

Stories

Imagine a snowy day where workers need to coat the roads. Regular bitumen is thick and hard to use, but cutback bitumen, being blended with solvents, glides smoothly over the surface, making their job easy even in winter.

Memory Tools

COLD – Cutback, Oil-based, Lower temperature, Dressing application.

Acronyms

C-BIT for Cutback Bitumen

= Cutback

= Blended

= Inexpensive to apply

= Temperature friendly.

Flash Cards

Glossary

- Cutback Bitumen

A type of bitumen obtained by blending bitumen with volatile solvents to reduce viscosity for easier application.

- Viscosity

A measure of a fluid's resistance to flow; lower viscosity means a fluid is thinner and flows more easily.

- Surface Dressing

A road maintenance technique involving the application of a thin layer of surface material to improve the road surface.

- Volatile Solvent

A solvent that has a high vapor pressure at room temperature, making it capable of evaporating easily.

Reference links

Supplementary resources to enhance your learning experience.