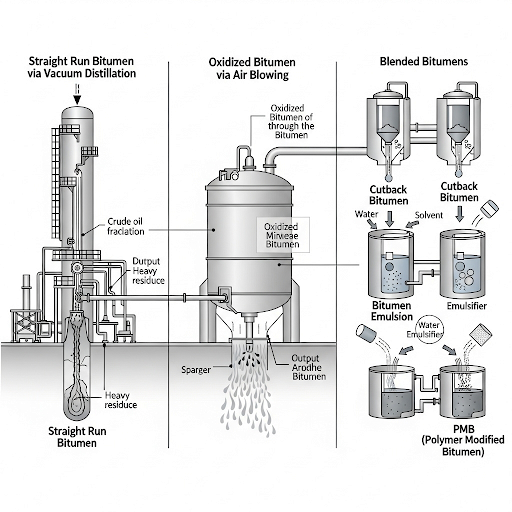

Refinery Flow Chart for Bitumen Production

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

The Refinery Process

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss the major steps in the refinery process for bitumen production. Can anyone tell me what the first step is?

Is it crude oil?

Correct! We begin with crude oil. The next step involves pre-heating and desalting. Who can share why desalting is important?

It removes salt and impurities that could affect the refining process!

Exactly! By removing salts, we ensure that the distillation process goes smoothly.

Distillation Phases

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to the distillation phases. Can anyone explain the difference between atmospheric and vacuum distillation?

Atmospheric distillation separates lighter components at normal pressure, while vacuum distillation works at lower pressures to avoid cracking!

Good job! This difference is crucial because it allows us to obtain high-quality vacuum residue. What do we obtain from vacuum distillation?

We get 'short residue', which is used for producing different types of bitumen.

Right again! Short residue is our starting point for bitumen production options.

Bitumen Production Options

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, we have our short residue. What options do we have for its further processing?

We can make straight run bitumen or oxidized bitumen!

Correct! Straight run bitumen is used directly in construction. And oxidized bitumen is created through air blowing. Who can explain how air blowing affects the properties of bitumen?

It increases the viscosity and softening point, making it more suitable for roofing and industrial needs!

Excellent point! And what about blending?

Blending mixes it with solvents to create cutback bitumen which is useful in cold temperatures.

Exactly! Blending allows us to use bitumen even when conditions are less than ideal.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The refinery flow chart for bitumen production details the sequence of processes starting from crude oil to the final bitumen products, including pre-heating, distillation, and further processing options.

Detailed

Detailed Overview

The production of bitumen in petroleum refineries involves a systematic process that includes several critical steps. It begins with Crude Oil, which is then subjected to pre-heating and desalting to prepare it for distillation. The atmospheric distillation phase follows, where lighter hydrocarbons are separated based on their boiling points. The remaining heavy residue moves on to vacuum distillation, which effectively isolates what is known as vacuum residue or short residue. This residue can then lead to various bitumen production options:

- Option A: Straight Run Bitumen is extracted directly from vacuum distillation for immediate use in road construction.

- Option B: Air Blowing which results in Oxidized Bitumen, enhancing properties like viscosity for industrial applications.

- Option C: Blending, where the vacuum residue is mixed to create Cutback Bitumen or Emulsions, suitable for various weather conditions, or Polymer Modified Bitumen (PMB), offering enhanced performance suitable for heavy traffic and extreme circumstances.

These processes are crucial for tailoring the properties of bitumen needed for diverse civil engineering needs.

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Bitumen Production Process

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Below is a simplified flow of bitumen production in petroleum refineries:

1. Crude Oil ↓

2. Pre-heating and Desalting ↓

3. Atmospheric Distillation ↓

4. Vacuum Distillation ↓

5. Vacuum Residue (Short Residue) → Option A: Straight Run Bitumen → Option B: Air Blowing → Oxidized Bitumen → Option C: Blending → Cutback Bitumen / Emulsions / PMB

Detailed Explanation

This chunk outlines the sequential steps involved in producing bitumen from crude oil at a petroleum refinery. The process starts with crude oil, which undergoes pre-heating to remove salt and impurities. Then, it is separated into different fractions through atmospheric distillation. The heavy residue that remains after this step is processed using vacuum distillation, from which bitumen is derived. At this stage, options are available based on the desired type of bitumen: straight run bitumen, oxidized bitumen, or other blended forms.

Examples & Analogies

Imagine making a layered cake. First, you mix all the ingredients (crude oil). You then bake the cake at the right temperature (pre-heating and desalting). After baking, you cut the cake into layers based on thickness (atmospheric distillation), and finally, you can add toppings or fillings to create different flavors (oxidized or blended bitumen) depending on what you want to serve.

Key Concepts

-

Crude Oil: The starting material for bitumen production that undergoes refining processes.

-

Atmospheric and Vacuum Distillation: Critical processes that separate crude oil into various components.

-

Short Residue: The material remaining after distillation used for bitumen.

-

Processing Options: The ways in which short residue can be converted into different types of bitumen.

Examples & Applications

Example of Straight Run Bitumen: Produced directly from vacuum distillation and used in standard road construction.

Example of Oxidized Bitumen: Used for roofing materials due to its enhanced viscosity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Crude oil to heat, the first step's a feat! Distill it right, then options ignite!

Stories

Imagine a bustling refinery where crude oil arrives, transforming through heat and pressure into the vast products we rely on for roads and roofs.

Memory Tools

C-PAD for the process: 'Crude, Preheat, Atmospheric, Distillation.' Each step gets us closer to bitumen.

Acronyms

USE for the types of bitumen

Straight Run (Unmodified)

Oxidized (from air)

and Emulsions (for wet conditions).

Flash Cards

Glossary

- Crude Oil

Unrefined petroleum extracted from the earth, containing various hydrocarbons.

- Atmospheric Distillation

A process that separates different hydrocarbon fractions based on boiling points at atmospheric pressure.

- Vacuum Distillation

A distillation process conducted under reduced pressure to avoid thermal cracking of components.

- Short Residue

The heaviest fraction left after atmospheric distillation, serving as feedstock for bitumen production.

- Straight Run Bitumen

Bitumen directly obtained from vacuum distillation, used mainly in road construction.

- Oxidized Bitumen

Bitumen that has been treated with air to alter its properties, increasing viscosity and softening point.

- Cutback Bitumen

Bitumen blended with a volatile solvent to lower its viscosity for easier application.

- Emulsions

Mixtures of bitumen with water and emulsifying agents, allowing usage in damp conditions.

- Polymer Modified Bitumen (PMB)

Bitumen enhanced with polymers for improved elasticity and performance under heavy loads.

Reference links

Supplementary resources to enhance your learning experience.