Industrial Bitumen Production Units

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Essential Equipment in Bitumen Production

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will explore the essential equipment used in industrial bitumen production, starting with distillation columns. Can anyone tell me what distillation columns do?

They separate different components of crude oil based on their boiling points.

Exactly, Student_1! Distillation columns are crucial for separating lighter hydrocarbons from heavier residues. This brings us to our next equipment: vacuum pumps. Who can explain why vacuum pumps are important?

They help avoid thermal cracking during the vacuum distillation process by maintaining lower pressures.

Correct! This process is essential for producing a heavy residue suitable for bitumen production. Let's move on to air blowing reactors—can anyone explain their purpose?

They blow hot air through the residue to enhance the bitumen’s properties.

Well done, Student_3! This oxidation process increases bitumen's viscosity and softening point, making it more suitable for various applications. Remember, we can summarize this equipment as the 'D-VAB-H' method—Distillation, Vacuum, Air Blowing, Heat Exchangers, and Blending!

To recap, the key equipment includes distillation columns, vacuum pumps, air blowing reactors, heat exchangers, storage tanks, and blending units. Each plays a significant role in ensuring the effective production of bitumen. Great job today, everyone!

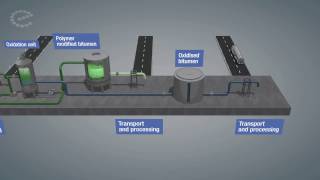

Process Flow of Bitumen Production

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's put together everything we've learned about the equipment with the production process flow. Who can briefly summarize the sequence of operations in bitumen production?

First, crude oil is pre-heated, then transported to the distillation columns, followed by vacuum distillation, and finally, air blowing and blending.

Exactly, Student_4! This sequence is crucial for efficiently transforming crude oil into usable bitumen. The blending steps are particularly important for creating the final product types like oxidized bitumen and bitumen emulsions, right?

Yes! The blending units are where we create specific formulations for different applications.

Correct! And why do you think temperature control is crucial in the storage tanks?

To maintain the properties of bitumen and prevent it from hardening or degrading.

Well said, Student_2! Maintaining optimal temperature ensures the bitumen remains in the right state for use. To summarize, the process includes preheating, distillation, air blowing, and blending, critical for creating quality bitumen. Fantastic discussion today!

Importance of Each Production Unit

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive deeper into why each of the production units is essential for bitumen quality. Starting with distillation columns—what are some of the consequences if they malfunction?

If they malfunction, we might not separate the hydrocarbons correctly, resulting in low-quality bitumen.

Exactly! Poor separation leads to inefficiencies and ultimately affects the durability of the final product. Now, what about vacuum pumps? Student_4?

If they fail, we could risk thermal cracking, which damages the vacuum residue.

Correct! This emphasizes why proper maintenance is crucial. Finally, how do air blowing reactors contribute to the properties of bitumen?

They oxidize the bitumen, improving its softening point and viscosity for various applications.

Great job, Student_1! Without this step, the bitumen would lack the necessary hardness and stability for road construction. Let's remember: each unit holds significance for achieving quality in bitumen production.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section details the key equipment and facilities necessary for industrial-scale bitumen production, including distillation columns, vacuum pumps, and oxidation reactors. Understanding the functionality of these units is crucial for optimizing the production process.

Detailed

Industrial Bitumen Production Units

Industrial-scale production of bitumen necessitates the use of specialized equipment designed to handle the various processes involved in extracting bitumen from crude oil. The following are key components:

- Distillation Columns: Essential for the fractional distillation process of crude oil to separate lighter hydrocarbons from heavier residues, resulting in bitumen.

- Vacuum Pumps: Utilized during vacuum distillation to prevent thermal cracking of long residues, ensuring that the heavy residue remains suitable for bitumen production.

- Air Blowing Reactors: Used in the oxidation process that involves blowing hot air through the vacuum residue, enhancing the properties of the bitumen, such as increasing its viscosity and softening point.

- Heat Exchangers: Critical for maintaining operational temperatures during the distillation and oxidation processes, facilitating energy efficiency.

- Storage Tanks with Temperature Control: Necessary for storing the bitumen while ensuring it remains at optimal temperatures to maintain its properties.

- Blending and Packaging Units: These are used for mixing the bitumen with other materials or modifying it into different types of bitumen products before it is packaged for distribution.

Understanding these components is vital for engineers and technicians involved in the bitumen production industry as they directly influence the quality and efficiency of the final product.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Specialized Equipment for Bitumen Production

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industrial-scale bitumen production requires specialized equipment:

• Distillation Columns

• Vacuum Pumps

• Air Blowing Reactors

• Heat Exchangers

• Storage Tanks with Temperature Control

• Blending and Packaging Units

Detailed Explanation

To produce bitumen on an industrial scale, specific types of equipment are necessary.

- Distillation Columns: These are used to separate different components of crude oil based on their boiling points. The crude oil is heated and vaporized, then captured in different trays of the column to collect lighter fractions at various levels.

- Vacuum Pumps: These are installed to create a vacuum environment, which allows for the distillation of heavier residues at lower temperatures to prevent thermal cracking.

- Air Blowing Reactors: In this step, air is blown through the vacuum residue to oxidize it and enhance the properties of the bitumen, such as viscosity and softening point.

- Heat Exchangers: These are critical for maintaining optimal temperatures throughout the production process. They transfer heat efficiently between fluids within the system.

- Storage Tanks with Temperature Control: Proper storage is essential to maintain the quality of bitumen, and temperature control ensures that the material remains in a workable state.

- Blending and Packaging Units: After production, bitumen may need to be blended with other materials or prepared for packaging into containers for distribution.

Examples & Analogies

Think of an industrial bitumen production unit like a restaurant kitchen. The distillation columns are like cooking pots where different ingredients are combined and heated to create a dish. Vacuum pumps help extract flavors without burning the meal (like sous-vide cooking), while air blowing reactors are akin to using a mixer to aerate a batter for a cake, enhancing its properties. Heat exchangers function like a stove that ensures the right temperature, and storage tanks are like keeping cooked food warm until served. Finally, the blending and packaging units can be compared to the presentation stage, where the dish is plated and ready to be delivered to customers.

Key Concepts

-

Distillation: The process of separating crude oil into various components based on boiling point.

-

Vacuum Distillation: A critical step to avoid thermal cracking while producing heavy residues.

-

Air Blowing: A process that enhances the properties of bitumen by oxidizing it with hot air.

-

Heat Management: Ensures the distillation and oxidation processes operate under optimal conditions.

Examples & Applications

Distillation columns work like tall tubes where crude oil enters, heats up, and separates into various lighter and heavier components based on boiling points.

Air blowing reactors are similar to blow dryers, but instead of drying hair, they blow hot air through the oily residue to change its properties.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the columns, oil’s split, by heat’s rise, it gets fit!

Stories

Imagine a factory where crude oil is like a canvas, and each piece of equipment is an artist making a perfect bitumen painting, ensuring every color (component) is just right.

Memory Tools

Remember as 'D-VAB-H': Distillation, Vacuum, Air Blowing, Blending, Heat for gathering knowledge.

Acronyms

D-VABH - Distillation, Vacuum, Air Blowing, Blending, Heat Exchangers in bitumen production creation!

Flash Cards

Glossary

- Distillation Columns

Equipment that separates crude oil into various components based on their boiling points.

- Vacuum Pumps

Devices that maintain low pressure in distillation to prevent thermal cracking of the heavy residue.

- Air Blowing Reactors

Units that introduce hot air to oxidize bitumen, increasing its viscosity and softening point.

- Heat Exchangers

Equipment that maintains operational temperatures during distillation and oxidation processes.

- Storage Tanks

Containers that store bitumen at regulated temperatures to preserve its properties.

- Blending Units

Facilities used for mixing bitumen with other materials or modifying it for specific applications.

Reference links

Supplementary resources to enhance your learning experience.