Production of Bitumen from Petroleum

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Crude Oil Distillation Process

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we are going to talk about how bitumen is produced from crude oil. Can anyone tell me what the first step is in this process?

Is it heating the crude oil?

Exactly! We begin by **preheating** crude oil to around 400°C. Why do you think heating is important?

To separate the different components based on boiling points?

That's right! The preheated crude oil then goes into the **distillation column** for **atmospheric distillation** where lighter fractions like gasoline and kerosene are separated out.

What happens to the heavier residues?

Great question! After atmospheric distillation, we deal with the **long residue**. This undergoes **vacuum distillation**, where it's distilled under vacuum conditions to avoid thermal cracking.

What do we get from vacuum distillation?

We obtain a heavy residue known as vacuum residue or **short residue**, which serves as our primary feedstock for bitumen production. So, what are the main types of distillation we've discussed?

Atmospheric and vacuum distillation!

Correct! Understanding these steps is crucial for knowing how we transform crude oil into useful bituminous materials.

Air Rectification or Oxidation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know how we get our vacuum residue, let's talk about what happens next. Can someone remind me what air rectification does?

It enhances the properties of the bitumen, right?

Exactly! In the **air blowing process**, hot air is blown through the vacuum residue at temperatures between 200-300°C. What happens when oxygen reacts with hydrocarbons during this process?

It increases the viscosity and softening point of the bitumen.

Very good! This results in oxidized bitumen, which has higher temperature stability and is ideal for applications like roofing. Why do you think high softening points are an important property for these applications?

Because it needs to resist heat without losing its form!

Exactly! High softening points ensure that the bitumen can withstand various environmental conditions while maintaining its effectiveness. What are some uses for oxidized bitumen?

It's used in roofing and waterproofing!

That's correct! Understanding the properties of oxidized bitumen helps us know how to utilize it effectively.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In the production of bitumen from petroleum, crude oil undergoes a series of distillation processes to separate components, resulting in valuable heavy residues which can be further refined into different types of bitumen for various applications.

Detailed

Detailed Summary

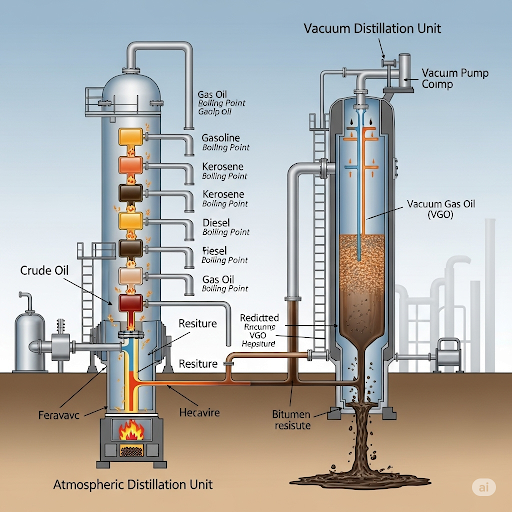

The production of bitumen from petroleum is a key aspect of its utilization in construction and infrastructure development. The primary method of obtaining bitumen is through the fractional distillation of crude oil. The first step involves heating the crude oil to around 400°C, followed by its introduction into a distillation column. Here, lighter hydrocarbons are separated based on their boiling points in two main phases:

- Atmospheric Distillation: This process separates the lighter fractions, such as gasoline and diesel.

- Vacuum Distillation: This is a critical step where the residue left after atmospheric distillation undergoes further distillation under reduced pressure, producing what is known as vacuum residue or short residue. This residue is the primary feedstock for bitumen production.

The vacuum residue may then be processed further through air rectification or oxidation. By blowing hot air through the residue, the viscosity and softening point of the bitumen can be enhanced. This results in oxidized bitumen, which is particularly useful for industrial applications.

Understanding these production processes is essential as each type of bitumen produced serves distinct purposes in civil engineering, affecting how they are utilized in road construction and other applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Crude Oil Distillation Process

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The initial step in the production of bitumen is the fractional distillation of crude oil in a refinery. The process includes:

• Preheating of Crude Oil: Crude oil is first heated to around 400°C.

• Atmospheric Distillation: The heated crude enters a distillation column where lighter hydrocarbons (like gasoline, kerosene, diesel) are separated by their boiling points.

• Vacuum Distillation: The residue from atmospheric distillation, known as long residue, is further distilled under vacuum to avoid thermal cracking. This separates lubricating oils and leaves behind a heavy residue known as short residue or vacuum residue, which becomes feedstock for bitumen production.

Detailed Explanation

The production of bitumen starts with crude oil distillation. First, crude oil is heated to about 400°C to separate various hydrocarbon compounds based on their boiling points. This process is called atmospheric distillation, where lighter components like gasoline and diesel are extracted. Next, the heavier leftover liquid, known as long residue, undergoes vacuum distillation. By applying a vacuum, the temperature is lowered to prevent thermal cracking of sensitive hydrocarbons, resulting in a heavier residue known as the short residue. This short residue is essential for producing bitumen.

Examples & Analogies

Think of the distillation process like cooking pasta. When you boil water and add pasta, it cooks differently based on its size and thickness. The thinner spaghetti cooks faster and rises to the top when it's ready, similar to how lighter hydrocarbons separate first. The thicker pasta takes longer and requires a lower temperature to cook properly without falling apart, just like how vacuum distillation separates heavier oils at lower temperatures.

Air Rectification or Oxidation

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The vacuum residue may undergo air blowing to enhance specific properties of bitumen. In this process:

• Hot air (200–300°C) is blown through the residue.

• The oxygen in the air reacts with the hydrocarbons, increasing viscosity and softening point.

This process produces oxidized bitumen, which has higher softening points and is more suitable for industrial applications such as roofing and pipe coating.

Detailed Explanation

After obtaining the vacuum residue, the next step is to enhance its properties through oxidation. Hot air at temperatures ranging from 200°C to 300°C is blown into the residue. During this process, the oxygen in the air chemically reacts with the hydrocarbons in the residue. This reaction increases the viscosity and softening point of the bitumen, producing oxidized bitumen. This type of bitumen is ideal for various industrial applications, especially in situations that require a stronger binding agent, such as roofing materials and pipe coatings.

Examples & Analogies

Consider how cooking eggs changes their texture. When you add air and heat to egg whites, they become fluffy and thick, much like how blowing hot air into the vacuum residue changes its properties. Just like fluffy eggs are better for certain recipes, oxidized bitumen has traits that make it more effective for specific industrial tasks.

Key Concepts

-

Fractional Distillation: A method to separate crude oil into various components based on boiling points.

-

Vacuum Distillation: A process that refines heavier oil fractions without causing thermal breakdown.

-

Oxidized Bitumen: A type of bitumen with enhanced properties obtained through air blowing.

Examples & Applications

In the vacuum distillation process, the residual product after separating lighter hydrocarbons serves as the main raw material for producing bitumen.

Oxidized bitumen is often used in roofing materials because of its high softening point, making it effective in varied weather conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To make bitumen that's good for the road, distill that oil, then air is blowed.

Stories

Once upon a time in a refinery, a batch of crude oil wanted to be something more. It began its journey heated fiercely, separating to reach its final form—bitumen, ready for roads!

Memory Tools

FAVO: Fractional distillation, Atmospheric, Vacuum distillation, Oxidation - the steps to produce quality bitumen.

Acronyms

BAP

Bitumen

Air blowing

Properties - remember the enhancement of bitumen's properties through air blowing.

Flash Cards

Glossary

- Crude Oil

A natural, unrefined petroleum product composed of hydrocarbon deposits and other organic materials.

- Fractional Distillation

A process to separate a mixture into its component parts based on differences in boiling points.

- Vacuum Distillation

A distillation process conducted under reduced pressure to prevent thermal degradation of the product.

- Vacuum Residue

The heavy material left after atmospheric distillation used as feedstock for bitumen production.

- Oxidized Bitumen

Bitumen that has undergone air blowing to enhance viscosity and softening point.

Reference links

Supplementary resources to enhance your learning experience.