Straight Run Bitumen

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Straight Run Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to talk about Straight Run Bitumen. How many of you are familiar with the term 'bitumen'?

I've heard about it in the context of road construction.

Exactly! Bitumen is a key binder in roads. Now, Straight Run Bitumen, specifically, is obtained from vacuum distillation. Who can tell me why vacuum distillation is important?

Is it to prevent thermal cracking while processing?

Yes, that's correct! This helps in maintaining the integrity of the bitumen. Remember the acronym 'V-SAVE' to recall the vital elements: Vacuum, Soft, Adhesive, Viscous, and Entering a new phase.

Can Straight Run Bitumen be modified?

Great question! It typically isn't modified before its use in road construction, enhancing its role as an efficient and reliable material.

To summarize, Straight Run Bitumen is crucial for road construction without modification, directly enhancing road durability and performance.

Applications of Straight Run Bitumen

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s focus on the applications of Straight Run Bitumen. Why do engineers prefer this type for road construction?

Because it's directly usable and doesn’t require further treatment?

Exactly! This direct usage simplifies the process and reduces costs. How does this benefit the environment?

Perhaps it minimizes waste since it skips additional processing?

Spot on! Less processing means fewer emissions and a more efficient use of resources. Always remember this relationship when working on projects involving bitumen.

In summary, the direct applicability of Straight Run Bitumen significantly enhances road quality while being cost-effective and environmentally considerate.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses Straight Run Bitumen, a type of bitumen obtained directly from the vacuum distillation process of crude oil. It highlights its applications in road construction, indicating its importance in ensuring durable pavements without further modifications.

Detailed

Straight Run Bitumen

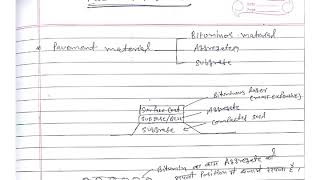

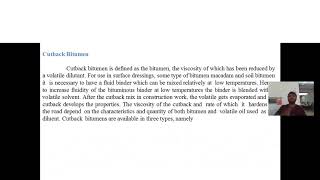

Straight Run Bitumen is defined as the type of bitumen obtained directly through the vacuum distillation of crude oil. Unlike other variants such as oxidized or cutback bitumen, Straight Run Bitumen is used primarily in road construction without further modification, making it crucial for both flexibility and durability of pavements.

Key Points:

- Production Method: It is extracted during the distillation process after the heaviest oil fractions have been separated. This means that it is derived from high-quality feedstock, which aids in its effective performance in road applications.

- Uses: It is often referred to as penetration grade bitumen and is typically utilized for surfacing roads due to its adhesive properties and ability to withstand environmental influences.

- Importance: Understanding its characteristics and applications is essential for engineers, as it influences the overall effectiveness and longevity of roadways. Arachnophobia, for example, illustrates how knowledge of the material directly impacts engineering decisions.

In summary, Straight Run Bitumen is vital in meeting the infrastructure needs of society through road construction, ensuring durability and functional integrity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Straight Run Bitumen

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Obtained directly from vacuum distillation.

• Used in road construction without further modification.

• Also called penetration grade bitumen.

Detailed Explanation

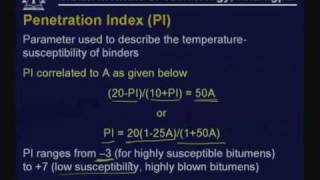

Straight Run Bitumen is a type of bitumen that is produced directly from the vacuum distillation process of petroleum. This means it doesn’t undergo any additional refining or modification after the initial extraction. It is categorized as a penetration grade bitumen, which refers to its consistency and softness, indicated by its penetration value. The penetration value measures how far a standard needle can penetrate into the bitumen under specific conditions. The higher the penetration value, the softer the bitumen.

Examples & Analogies

Think of Straight Run Bitumen like freshly squeezed orange juice. Just as you get juice directly from the oranges without any additives, Straight Run Bitumen comes straight from the refining process without additional chemicals. It's pure and retains its essential properties, making it suitable for immediate use in road construction.

Applications of Straight Run Bitumen

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Used in road construction without further modification.

Detailed Explanation

Straight Run Bitumen is primarily used in road construction. Its unmodified nature makes it ideal for use in flexible pavements, where it binds with aggregates to create a strong and durable surface. Because it does not require further modification, it is efficient for contractors to work with and is often selected for projects needing immediate results, like paving new roads or repairing existing ones.

Examples & Analogies

Consider how a baker uses flour to make bread. Just as bread can be baked directly with flour without needing any other ingredients for simple loaves, Straight Run Bitumen can be used directly in asphalt mixtures for roads. It's a straightforward, reliable choice for construction.

Characteristics of Straight Run Bitumen

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Also called penetration grade bitumen.

Detailed Explanation

Straight Run Bitumen is also known as penetration grade bitumen due to its defined grading based on viscosity and penetration characteristics. This type of bitumen functions well at different temperatures due to its ability to maintain its properties as conditions change. The penetration grade categorizes the bitumen based on how soft or hard it is, thus influencing its application in varying environmental and loading conditions.

Examples & Analogies

Think of ice cream, which can be soft or hard depending on how cold it is. Just like you select ice cream based on its firmness for a sundae or a cone, engineers choose specific grades of Straight Run Bitumen based on its penetration grade, ensuring it meets the demands of the roads being constructed.

Key Concepts

-

Straight Run Bitumen: A bitumen type obtained directly from vacuum distillation used in flexible pavements.

-

Vacuum Distillation: A method for separating crude oil components under reduced pressure to prevent thermal breakdown.

Examples & Applications

A common use of Straight Run Bitumen is in high-traffic highways where durability is essential.

In a local road project, Straight Run Bitumen was chosen because it provided cost savings by eliminating the need for additional modifications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the heat of the day, with oil we play, Vacuum distillation keeps thermal cracks away.

Stories

Once upon a time in a land of heavy trucks, Straight Run Bitumen stood strong, showing it’s meant for the rocks. It didn’t need changes, just placed on the ground, the roads it paved kept moving all around.

Memory Tools

Remember V-SAVE: Vacuum, Soft, Adhesive, Viscous, Essential for roadways!

Acronyms

SVB

Straight Run

Vacuum Distillation

Bitumen.

Flash Cards

Glossary

- Straight Run Bitumen

Bitumen obtained directly from the vacuum distillation of crude oil, used primarily without modifications in road construction.

- Vacuum Distillation

A distillation method that involves heating crude oil in a vacuum to separate its components while avoiding thermal cracking.

- Penetration Grade

A classification of bitumen based on its ability to flow or penetrate under specific conditions.

Reference links

Supplementary resources to enhance your learning experience.