Quality Control in Bitumen Production

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Quality Control Tests

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will be discussing quality control in bitumen production. Can anyone tell me why quality control is so important?

Is it to make sure the bitumen is safe to use?

Exactly! Quality control ensures that the bitumen meets performance standards. One method we use is the penetration test, which measures how deep a needle penetrates bitumen.

What does that tell us about the bitumen?

Great question! It indicates the hardness of the bitumen, which is crucial for its application in various climates.

So, does harder bitumen mean it can withstand more traffic?

That's a part of it. In many cases, yes! Bitumen must be suitably graded for the conditions it will face.

What other tests are there?

We also perform the softening point test, ductility test, viscosity test, flash and fire point test, and specific gravity test, each serving a unique purpose.

To summarize, quality control tests help us confirm that bitumen will perform well under the specific conditions of use.

Detailed Discussion of Quality Tests

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore each of the quality tests we mentioned in detail. First, who remembers what the softening point test measures?

It measures the temperature where bitumen starts to flow?

Correct! This is vital in determining how the bitumen will behave in different climates. For instance, it prevents issues in hot weather.

What about the ductility test?

The ductility test measures how much a sample can stretch before breaking. It's crucial for ensuring flexibility in applications.

And what does the viscosity test do?

It assesses how easily the bitumen can be worked with, influencing how it’s applied in the field.

What about safety? How is that tested?

Excellent point! The flash and fire point tests ensure that the bitumen handles safely at high temperatures. This is very important during production!

In conclusion, every test plays a role in assuring the performance and safety of bitumen in construction.

The Importance of Quality Control in Different Conditions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about how these tests help in various climates. For example, why do we conduct the specific gravity test?

Maybe to ensure the right type of bitumen is used for different conditions?

Exactly! The specific gravity informs us about the density, which impacts performance under different traffic loads.

So heavy traffic areas need specific types of bitumen?

Yes, heavy traffic areas often require more robust bitumen, and the tests help us determine the best fit.

And in colder climates?

In colder climates, the ductility and softening point tests are vital. Here, we want bitumen that can flex without cracking.

How do we know when it's not suitable?

If any test results fall outside the acceptable ranges, it indicates that the bitumen may not perform well in that environment.

In summary, targeted quality control ensures that we use the right type of bitumen, enhancing safety and performance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Quality control in bitumen production is critical to ensure that the material meets the necessary standards for performance in construction. Key tests include the penetration test, softening point test, and others, which guarantee the bitumen's suitability for different climatic conditions and traffic types.

Detailed

Quality Control in Bitumen Production

Quality control is a crucial aspect of bitumen production, ensuring that the final product meets the required specifications for its intended use in construction. Various testing methods are employed to evaluate the quality of bitumen, focusing on its physical properties that determine performance.

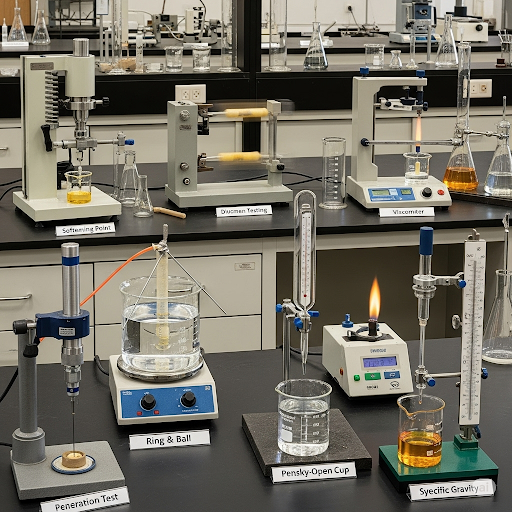

The primary tests include:

- Penetration Test: Measures the depth that a standard needle penetrates into a sample of bitumen under specific conditions, indicating its hardness and suitability for applications.

- Softening Point Test: Determines the temperature at which bitumen begins to flow. This is crucial for understanding how bitumen will behave in different climatic conditions.

- Ductility Test: Assesses the strength of the bitumen by measuring its ability to stretch without breaking, crucial for applications requiring flexibility.

- Viscosity Test: Measures the internal friction of the bitumen, affecting how easily it can be worked with during application.

- Flash and Fire Point Test: Identifies the temperatures at which the bitumen can ignite or produce flammable vapors, ensuring safety during handling.

- Specific Gravity Test: Provides information on the density of the bitumen, which influences its behavior and application suitability.

These tests collectively ensure that the bitumen produced will perform adequately under varying environmental and traffic conditions, thus maintaining safety and performance standards in road construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Quality Testing Parameters

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To ensure consistent quality, bitumen is tested and graded using various parameters:

Detailed Explanation

Quality control is crucial in bitumen production because it ensures that the bitumen meets the necessary standards for various applications. Testing involves several methods, each designed to measure specific properties of the bitumen. These tests help determine if the bitumen is suitable for use under different climatic and traffic conditions.

Examples & Analogies

Think of quality control in bitumen production like baking a cake. Just as you check the cake by testing its texture and taste to ensure it is perfect before serving, manufacturers test bitumen to confirm it meets specific criteria before using it in roads.

Penetration Test

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Penetration Test

Detailed Explanation

The penetration test measures the hardness or softness of bitumen. A needle is pushed into a sample of bitumen under a standard load and for a specific duration. The depth of penetration helps classify the bitumen, indicating its suitability for various applications. Softer bitumens will penetrate more, whereas harder ones will penetrate less.

Examples & Analogies

Imagine using your finger to press into soft dough versus hard bread. The depth to which your finger sinks represents how soft or hard the material is, similar to how the needle penetrates the bitumen.

Softening Point Test

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Softening Point Test

Detailed Explanation

This test determines the temperature at which bitumen softens and flows under specified conditions. It is vital as it indicates how the bitumen will behave in different weather conditions—whether it will remain solid or become too soft and lose its structural integrity. The softening point is especially important in warm climates.

Examples & Analogies

Think about how ice cream melts on a hot day. Just as ice cream softens and becomes less stable with heat, bitumen's softening point indicates at which temperature it may lose its strength.

Ductility Test

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Ductility Test

Detailed Explanation

The ductility test measures the ability of bitumen to stretch without breaking. A sample is pulled apart at a specific speed, and the distance it elongates before breaking indicates its ductility. Good ductility indicates that bitumen can accommodate the stresses and deformations in road applications.

Examples & Analogies

Consider how a rubber band stretches before it snaps. In this analogy, ductility is similar to the rubber band's ability to stretch without breaking, which is crucial for materials subjected to tensile stresses.

Viscosity Test

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Viscosity Test

Detailed Explanation

The viscosity test measures the thickness of the bitumen and its ability to flow. It is crucial because the viscosity of bitumen changes with temperature; higher temperatures can lower viscosity, making the material more workable. Understanding viscosity helps in determining how bitumen behaves during and after application.

Examples & Analogies

Imagine syrup versus water—syrup is thicker and flows more slowly than water. This difference in viscosity helps you understand how bitumen will flow and spread on a road.

Flash and Fire Point Test

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Flash and Fire Point Test

Detailed Explanation

The flash and fire point tests assess the safety of handling bitumen. The flash point is the lowest temperature at which vapors can ignite, while the fire point is where continuous combustion occurs. These tests are crucial for implementing safety measures during bitumen production and transportation.

Examples & Analogies

Think of how a candle works—when the wick gets too hot, it can catch fire. Just like needing to know the risks of flames near a candle, understanding the flash and fire points helps ensure safe handling of bitumen.

Specific Gravity Test

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Specific Gravity Test

Detailed Explanation

The specific gravity test measures the density of bitumen compared to water. This property is essential for ensuring bitumen is the right weight for applications and for understanding its behavior in mixtures with aggregates. A higher specific gravity typically indicates heavier bitumen.

Examples & Analogies

Consider how an object floats or sinks in water. A heavier object (higher specific gravity) will sink while a lighter one will float. This principle helps us gauge how bitumen will interact with other materials in construction.

Key Concepts

-

Quality Control Tests: Essential assessments like penetration, softening point, ductility, viscosity, flash and fire point, and specific gravity tests.

-

Performance Assurance: Testing ensures that bitumen can withstand specific climates and traffic conditions.

Examples & Applications

The penetration test indicates that bitumen with a penetration value of 50 is suitable for areas with medium traffic, while a softer bitumen with a penetration value of 70 might be ideal for low traffic areas.

A softening point of 50°C could be problematic in high-temperature environments, suggesting the need for modified bitumen.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If safety’s your concern in the heat, the Flash Point Test simply can’t be beat!

Stories

Imagine a highway engineer who selects the right bitumen. Each time they pass a test, they ensure it won’t crack in winter, flow in summer, and keep traffic moving safely through all seasons.

Memory Tools

Use 'P-S-D-V-F-S' to remember the order of tests: Penetration, Softening point, Ductility, Viscosity, Flash and Fire, Specific gravity.

Acronyms

Remember the acronym 'P-S-D-V-F-S' for Penetration, Softening, Ductility, Viscosity, Flash/Fire, and Specific Gravity tests.

Flash Cards

Glossary

- Penetration Test

A test that measures the depth a needle penetrates into bitumen to assess its hardness.

- Softening Point Test

A test that determines the temperature at which bitumen starts to flow.

- Ductility Test

A test that measures a bitumen sample's ability to stretch without breaking.

- Viscosity Test

A test measuring the internal friction of bitumen, affecting its processability.

- Flash and Fire Point Test

Tests that identify the temperatures at which bitumen can ignite or produce flammable vapors.

- Specific Gravity Test

A test determining the density of bitumen, influencing its performance characteristics.

Reference links

Supplementary resources to enhance your learning experience.