Alkali-Aggregate Reactivity Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Alkali-Aggregate Reactivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome class! Today we'll discuss the Alkali-Aggregate Reactivity Test, which is essential for ensuring concrete durability. Why do you think it’s important to test aggregates for chemical reactivity?

Maybe to prevent future damages in concrete structures?

Exactly! Chemical reactions can cause expansions that lead to cracking. This test specifically looks for two main reactions: alkali-silica reaction and alkali-carbonate reaction.

How do we test for these reactions?

Good question! We use mortar bars and immerse them in a sodium hydroxide solution to simulate conditions. We then measure any expansion over 14 days.

Testing Procedure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s dive into the procedure. We start by preparing mortar bars. Can anyone tell me why we use mortar instead of regular concrete?

Is it because it allows for more detailed observation of the reactivity?

Precisely! After preparing the bars, they are immersed in the sodium hydroxide solution. Can anyone tell me what we are looking for during this immersion?

We're measuring the expansion of the bars, right?

Correct! If the expansion exceeds 0.1% in 14 days, the aggregate is considered potentially reactive, which is not suitable for concrete.

Types of Reactions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the types of reactions we test for. Can anyone name them?

There’s the alkali-silica reaction and the alkali-carbonate reaction, right?

Excellent! The alkali-silica reaction occurs with reactive silica aggregates, while the alkali-carbonate reaction involves certain carbonate rocks. Both can undermine concrete integrity.

How do we know if an aggregate is reactive?

That's what the test is for! If the expansion is within the acceptable limit, we consider the aggregate safe for use.

Significance and Conclusion

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, why is the Alkali-Aggregate Reactivity Test significant in construction?

It helps prevent damage and maintains the longevity of concrete structures!

Exactly! By identifying potential reactivity before construction, we can avoid costly repairs and ensure safety.

So, it’s really about preventing future problems!

Correct! Always remember that prevention is key in civil engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section describes the Alkali-Aggregate Reactivity Test, which identifies the possible alkali-silica and alkali-carbonate reactions that can adversely affect concrete structures. It specifies the testing procedures and acceptable expansion limits for mortar bars immersed in a sodium hydroxide solution.

Detailed

The Alkali-Aggregate Reactivity Test is crucial in determining the potential for chemical reactions between cement and certain aggregates, notably those rich in silica or carbonate. The test involves submerging mortar bars made from the aggregate in a sodium hydroxide (NaOH) solution, simulating concrete conditions. The main goal is to monitor any expansion that occurs over a 14-day period. According to the guidelines established in IS: 2386 (Part VII), the acceptable limit for expansion is less than 0.1%. Detecting reactivity early on can prevent severe long-term damage to concrete, thereby enhancing structural integrity and longevity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of the Test

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The purpose of the Alkali-Aggregate Reactivity Test is to detect potential chemical reactivity with cement in concrete.

Detailed Explanation

This test aims to identify whether certain aggregates can chemically react with alkaline components in cement. When aggregates react with alkalis in cement, they can expand over time, leading to serious structural issues in concrete. Thus, knowing if the aggregates have any potential for this reaction is crucial for ensuring the durability and longevity of concrete structures.

Examples & Analogies

Imagine you have a cake recipe that includes an ingredient that does not mix well with another. If you use that ingredient, your cake will rise too much and then collapse, ruining the cake. Similarly, if reactive aggregates are used in concrete, they can lead to cracking and structural failures.

Types of Reactions

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

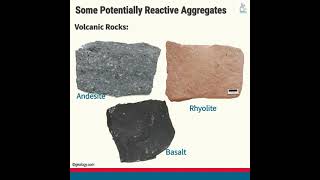

There are two main types of chemical reactions analyzed in this test: Alkali-silica reaction (ASR) and Alkali-carbonate reaction (ACR).

Detailed Explanation

Alkali-silica reaction occurs when reactive silica in aggregates reacts with alkalis in the cement, forming a gel that can absorb water and swell, causing cracks. Alkali-carbonate reaction, on the other hand, involves the reaction between alkalis and certain carbonate rocks, leading to similar expansion issues. Each reaction type poses unique risks to the integrity of concrete, making it essential to identify them.

Examples & Analogies

Think of ASR and ACR like two different types of tomatoes that can spoil a salad. One tomato might cause it to get overly soggy (ASR), while the other might cause the salad to taste off due to too much acidity (ACR). Both reactions can lead to a negative outcome for your concrete, just like spoiled tomatoes ruin a good salad.

Testing Procedure

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The procedure involves testing mortar bars for expansion in a sodium hydroxide (NaOH) solution.

Detailed Explanation

The process begins by preparing mortar bars using the aggregate in question. These bars are then submerged in a sodium hydroxide solution, which mimics the alkaline environment present in concrete. Over a specified period, typically 14 days, the bars are monitored for any expansion resulting from potential reactivity with the alkalis in the NaOH solution. The amount of expansion is measured to assess the reactivity of the aggregate.

Examples & Analogies

Imagine putting a piece of bread in a humid environment and observing how it becomes stale and expands. Here, the NaOH solution acts like the humidity for the mortar bars. Just as the bread's reaction can tell you if it will still be good to eat, the expansion of mortar bars tells us if the aggregates will behave well in concrete.

Acceptable Limits

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The acceptable limit for expansion is less than 0.1% in 14 days.

Detailed Explanation

In order to classify an aggregate as suitable for use in concrete, the expansion it demonstrates during this testing process must not exceed 0.1% after 14 days. If the expansion is greater than this limit, it indicates a higher risk of reactivity, which suggests that the aggregate could potentially compromise the structural integrity of the concrete in the long term.

Examples & Analogies

Consider a teacher grading a test where the highest score possible is 100%. A student needs to score below a certain percentage to pass (let's say 70%). If they exceed that limit, they don't pass. Similarly, if the aggregates expand more than 0.1%, they fail the reactivity test and are not suitable for use in concrete.

Key Concepts

-

Alkali-Aggregate Reactivity: The potential for chemical reactions between alkalis in cement and aggregates.

-

Testing Procedure: The steps to prepare mortar bars and evaluate their expansion in a NaOH solution.

-

Reactivity Types: The identification of alkali-silica and alkali-carbonate reactions.

Examples & Applications

If an aggregate exhibits an alkali-silica reaction, it may expand and crack over time, compromising concrete integrity.

Testing may reveal that a certain type of aggregate is unsuitable for use in an environment where sodium hydroxide is present.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When aggregates react, it’s a chemical fact; with NaOH, they might expand, causing concrete to be less grand.

Stories

Once, there was a concrete bridge, built with care but hiding a ridge; some aggregates felt the heat, with alkalis they couldn’t compete. Soon there were cracks, what a sad tale, if only they tested, they could prevail!

Memory Tools

A for Alkali, S for Silica, R for Reaction - remember 'ASR' for the test types.

Acronyms

ARE - Assess Reactivity of aggregates to prevent Expansion.

Flash Cards

Glossary

- AlkaliSilica Reaction (ASR)

A chemical reaction between alkalis in cement and reactive silica found in aggregates, causing expansion and cracking.

- AlkaliCarbonate Reaction (ACR)

A similar reaction involving certain carbonate aggregates and alkalis in cement that can lead to concrete failure.

- Mortar Bars

Specimens made of cement and aggregates used for testing in the Alkali-Aggregate Reactivity Test.

- Sodium Hydroxide (NaOH)

A chemical compound used in the test solution to simulate concrete conditions for the reactivity test.

- Expansion Limit

The maximum allowable expansion of mortar bars during the test, set at less than 0.1% in 14 days.

Reference links

Supplementary resources to enhance your learning experience.