Classification of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Source of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Alright class, today we'll start discussing the source of aggregates. Can anyone tell me what types of aggregates we find in nature?

Are natural aggregates like sand and gravel?

Exactly, Student_1! Natural aggregates include materials like sand, gravel, and crushed stone. Now, can anyone name types of artificial aggregates?

What about materials like slag?

Spot on! Slag and even sintered fly ash are examples of artificial aggregates. Lastly, does anyone know what recycled aggregates are?

Are they made from construction waste?

That’s correct! Recycled aggregates are derived from construction and demolition waste, helping to promote sustainability. Let's remember this using the acronym 'NAR' for Natural, Artificial, and Recycled.

Great job today! Let's summarize: natural aggregates come from the earth, artificial are man-made, and recycled come from previous constructions.

Size Classification of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dive into how we classify aggregates by size. What do you think is the difference between coarse and fine aggregates?

Coarse aggregates are larger, right?

Correct, Student_4! Coarse aggregates are retained on a 4.75 mm sieve, while fine aggregates pass through that and are retained on a 75 µm sieve. Can someone tell me what fillers are?

Fillers are the smallest particles that pass through the 75 µm sieve.

Exactly! And remember the sizes: coarse is greater than 4.75 mm, fine is between those sieves, and fillers are below 75 µm. Let’s memorize this using the mnemonic 'C-F-F': Coarse-Fine-Filler.

To wrap up, too small or too large can affect concrete performance, so we must choose wisely!

Shape Classification of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The last classification we need to discuss is shape. Can anyone describe the different shapes of aggregates?

There's rounded, angular, flaky, and elongated shapes.

Well done! Each shape has a unique impact on the strength and workability of the pavement mix. Why do you think rounded aggregates might be preferred in some cases?

Maybe they pack better and are easier to work with?

Absolutely! Rounded aggregates are known for better packing and lower friction. It helps to remember this by using the rhyming phrase 'Rounded sinks like a stone, angular stays alone'.

In summary, the shape affects the stability and workability of aggregates, crucial for proper pavement construction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section covers how aggregates are categorized into natural, artificial, and recycled types, further detailing size classifications as coarse, fine, and fillers, along with their shapes. Understanding this classification is crucial for determining their suitability for various pavement structures.

Detailed

Classification of Aggregates

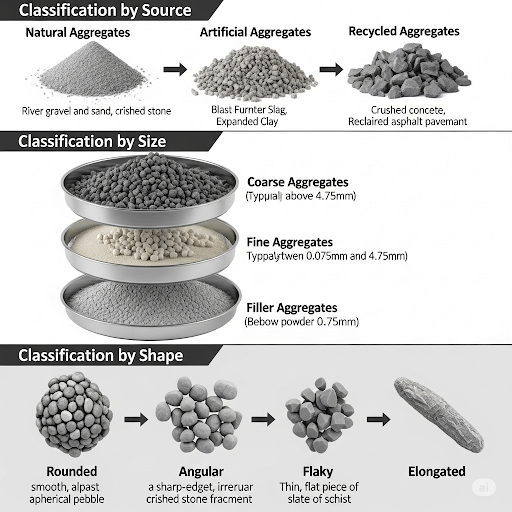

Aggregates, which constitute 70-80% of the volume of bituminous and cement concrete pavements, can be classified into multiple categories based on different attributes that affect the overall strength and durability of road infrastructure. The primary classifications discussed in this section include:

1. Source:

- Natural Aggregates: Include materials such as sand, gravel, and crushed stone derived from naturally occurring deposits.

- Artificial Aggregates: Comprised of human-made materials such as slag and sintered fly ash.

- Recycled Aggregates: These are extracted from construction and demolition waste, promoting sustainability in road construction.

2. Size:

- Coarse Aggregates: These are retained on a 4.75 mm IS sieve and generally include larger particles.

- Fine Aggregates: Pass through a 4.75 mm sieve but are retained on a 75 µm sieve, composed of smaller particles.

- Filler: This category consists of aggregates passing through the 75 µm sieve, generally dust-like particles.

3. Shape:

- Common shapes include rounded, angular, flaky, elongated, and those that are both flaky and elongated. The shape can significantly influence the packing density and compaction of the aggregates in the mixture.

Understanding these classifications helps in selecting the appropriate aggregate types based on their physical and mechanical properties, ultimately aiding in the development of robust pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Classification by Source

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates can be classified based on:

- Natural aggregates: Sand, gravel, crushed stone.

- Artificial aggregates: Slag, sintered fly ash.

- Recycled aggregates: Derived from construction and demolition waste.

Detailed Explanation

Aggregates can be grouped into three main categories depending on their origin:

- Natural aggregates are those that occur naturally, such as sand, gravel, and crushed stone. These materials are often collected directly from natural deposits and processed for construction use.

- Artificial aggregates are man-made and include materials such as slag and sintered fly ash, which are products of industrial processes. These materials can be engineered to provide specific properties that enhance construction performance.

- Recycled aggregates come from reprocessing waste materials generated in construction and demolition. This practice not only conserves natural resources but also reduces waste, making it an environmentally friendly option. Recycled aggregates may have different properties than natural aggregates, so it is essential to evaluate them for structural integrity before use.

Examples & Analogies

Think of aggregates like ingredients in a recipe. Just as you might choose between fresh produce (natural), canned goods (artificial), or leftovers (recycled) for your meal, construction projects choose the type of aggregate based on availability, cost, and desired qualities.

Classification by Size

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Coarse aggregates: Retained on 4.75 mm IS sieve.

- Fine aggregates: Pass through 4.75 mm IS sieve and retained on 75 µm sieve.

- Filler: Passes 75 µm sieve.

Detailed Explanation

The size of aggregates is another key classification, which significantly affects the properties of the concrete or asphalt mix:

- Coarse aggregates are larger particles that do not pass through a 4.75 mm sieve. These larger pieces provide strength and stability to the mix.

- Fine aggregates consist of smaller particles that pass through the 4.75 mm sieve but are retained on a 75 µm sieve. These fine aggregates help fill the voids between coarse aggregates, improving the dense packing of the mix.

- Filler refers to the finest particles that pass through the 75 µm sieve. Fillers ensure a smooth texture and can enhance others properties like workability and strength.

Examples & Analogies

Imagine making a layered cake. The coarse aggregates are like the large chunks of fruit in the batter, the fine aggregates are like the smooth cake mix, and the fillers are the frosting that fills in the small gaps and gives it a nice finish. Each size plays a crucial role in achieving the perfect cake, just like in a concrete mix.

Classification by Shape

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Rounded

- Angular

- Flaky

- Elongated

- Flaky and elongated

Detailed Explanation

Aggregates are also classified based on their shape, which influences how they behave in a mix:

- Rounded aggregates have smooth, curved surfaces, which makes them easier to work with because they flow freely when mixed.

- Angular aggregates have sharp edges and corners. These shapes interlock better, providing enhanced stability but can lead to higher friction in the mix.

- Flaky aggregates are thin and flat, while elongated aggregates are long and narrow. Both of these shapes can create packing problems and reduce the material's strength. The presence of flaky or elongated aggregates can lead to weaker concrete due to reduced bonding areas.

- Aggregates that are both flaky and elongated present the worst performance as they adversely affect the mix's strength and durability.

Examples & Analogies

Consider playing with different types of building blocks. Rounded blocks fit together easily and allow flexible designs, similar to how rounded aggregates work. On the other hand, angular blocks fit tightly together, making a sturdy structure but can be challenging to rearrange. Flaky and elongated blocks, however, are harder to stack and may topple over, representing the problems with using flaky and elongated aggregates in construction.

Key Concepts

-

Classification by Source: Aggregates can be classified into natural, artificial, and recycled based on their origin.

-

Classification by Size: Coarse aggregates are larger than 4.75 mm, fine aggregates are between 4.75 mm and 75 µm, and fillers are smaller than 75 µm.

-

Classification by Shape: The shape of aggregates influences how they pack and bond in concrete.

Examples & Applications

Natural aggregate examples include sand and gravel sourced from riverbeds.

Recycled aggregates can come from crushed concrete or bricks from demolition projects.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Aggregates from rock and soil, in coarse and fine, we toil.

Stories

Imagine building a road with different types of riches from nature, including sand at the beach and gravel from the hills. They all come together to create something strong.

Memory Tools

Remember NAR for the sources: Natural, Artificial, Recycled.

Acronyms

For size, use CFF

Coarse

Fine

Filler.

Flash Cards

Glossary

- Natural Aggregates

Materials like sand, gravel, and crushed stone that occur in nature.

- Artificial Aggregates

Man-made materials such as slag and sintered fly ash.

- Recycled Aggregates

Aggregates sourced from construction and demolition waste.

- Coarse Aggregates

Aggregates retained on a 4.75 mm sieve.

- Fine Aggregates

Aggregates passing through a 4.75 mm sieve and retained on a 75 µm sieve.

- Filler

Aggregates that pass through a 75 µm sieve.

- Shape

The physical form that influences the bonding and packing of aggregates.

Reference links

Supplementary resources to enhance your learning experience.