Soundness Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Soundness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we are going to learn about the Soundness Test. This test is crucial for assessing the durability of aggregates in road construction. Can anyone tell me why we would care about how aggregates respond to weathering?

Because if they break down, the road won't last long!

Exactly! The main goal is to ensure that the aggregates can withstand environmental challenges. Now, what specific environmental challenge do you think we are particularly concerned with?

Freeze-thaw cycles?

Correct! Freeze-thaw cycles can cause significant deterioration. The Soundness Test evaluates this by measuring the weight loss of aggregates after undergoing repeated wetting and drying. Remember the phrase 'freeze-thaw, measure and weigh' — it helps to keep our process in mind!

Procedure of the Soundness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s go over the procedure of the Soundness Test. Who can summarize what we need to do?

We need to soak the aggregates in sodium or magnesium sulfate solution and then dry them?

Great start! We soak them, dry them, and repeat this cycle. After a number of cycles, we measure the weight loss. Why do you think measuring weight loss is important?

It tells us how much the aggregates can withstand weathering!

Exactly right! The acceptable loss limits are <12% for sodium sulfate and <18% for magnesium sulfate. If it exceeds these, the aggregates may not be suitable. Let's remember these limits with the acronym 'S12-M18'.

Interpreting Results

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, what happens if the test results show a weight loss greater than the accepted limits?

We can't use those aggregates in construction!

Correct! This helps prevent premature road failures. Our goal is always to ensure that we use sound materials. Why is it essential for construction projects to prioritize soundness?

To save costs on repairs later!

Absolutely! A sound aggregate leads to longer-lasting pavements and reduces the need for maintenance. Excellent reasoning, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Soundness Test is critical in determining the durability of aggregates against weathering, particularly in environments with freeze-thaw cycles. By measuring weight loss in aggregate samples during repeated cycles of wetting and drying in sodium or magnesium sulphate, suitable aggregates for road construction can be identified. The acceptable weight loss limits are <12% for sodium sulphate and <18% for magnesium sulphate.

Detailed

Soundness Test

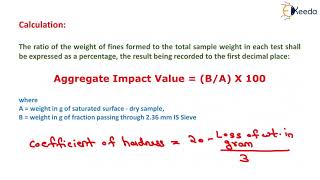

The Soundness Test is an essential standardized method for evaluating the durability of aggregates used in construction, specifically concerning their resistance to weathering processes such as freeze-thaw cycles. Conducted in accordance with IS: 2386 (Part V), this test involves subjecting aggregate samples to repeated cycles of wetting and drying in solutions of sodium or magnesium sulphate. The primary objective of this test is to measure any weight loss that occurs during these cycles, providing insight into the aggregate’s soundness and long-term performance in pavement applications.

Procedure

- Sample Preparation: Aggregate samples are prepared and placed in a sodium or magnesium sulphate solution.

- Cycles of Wetting and Drying: The samples undergo successive cycles of wetting and drying.

- Measurement: After the completion of the cycles, the weight loss of the aggregates is measured.

Significance

Understanding the weight loss helps in assessing the potential durability of aggregates under freeze-thaw conditions. The acceptable limits for weight loss are <12% for sodium sulphate and <18% for magnesium sulphate, ensuring that only aggregates that meet these criteria are used in pavement construction, thus enhancing road longevity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of the Soundness Test

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Purpose: Assess resistance to weathering, particularly freeze-thaw.

Detailed Explanation

The Soundness Test is designed to determine how well aggregates can withstand weathering processes. Specifically, it assesses their resistance to damage caused by repeated freeze-thaw cycles. This is crucial because in many climates, water can seep into the aggregates and freeze, causing them to expand. When the ice melts, the aggregates contract. This cycle can lead to deterioration over time, so understanding this property helps ensure durability in road construction.

Examples & Analogies

Think of a sponge that you leave outside in the rain and then freeze at night. Each time it gets wet and then freezes, it expands and contracts, which can lead to it breaking apart. Similarly, if aggregates in pavement can’t resist this freeze-thaw cycle, they will also break down.

Standard for the Soundness Test

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Standard: IS: 2386 (Part V).

Detailed Explanation

The Soundness Test follows a specific standard, IS: 2386 (Part V), which provides guidelines on how the test should be conducted and the acceptable limits for results. Following a standardized method ensures consistency and reliability in test results across different materials and laboratories. This is important for evaluating the quality of aggregates used in various asphalt and concrete mixtures.

Examples & Analogies

Just like a recipe for baking a cake needs to be followed precisely to ensure it turns out well, the Soundness Test requires adherence to a standard to ensure that the assessments of aggregate quality are accurate and dependable.

Procedure of the Soundness Test

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Procedure:

a. Samples are subjected to repeated cycles of wetting and drying in sodium or magnesium sulphate solution.

b. Weight loss is measured.

Detailed Explanation

The procedure for the Soundness Test involves placing aggregate samples in a solution of sodium or magnesium sulphate, which mimics the effects of weathering. The samples undergo cycles of drying and wetting that simulate natural environmental conditions. After completing several cycles, the weight of the aggregates is measured. A significant loss in weight indicates poor resistance to weathering, meaning the aggregate would not perform well in road constructions.

Examples & Analogies

Imagine leaving a block of ice outside in the winter, where it repeatedly melts and refreezes. If you check the ice after a while, you might find that a lot of it has chipped away or broken apart. The Soundness Test is similar, as it checks how much of the aggregate gets 'damaged' through such cycles.

Acceptable Values for Soundness Test

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Acceptable Values:

– <12% for sodium sulphate

– <18% for magnesium sulphate

Detailed Explanation

The results of the Soundness Test are compared against established acceptable values. For aggregates treated with sodium sulphate, the acceptable weight loss is less than 12%, indicating good resistance. For those treated with magnesium sulphate, the acceptable weight loss is less than 18%. Aggregates that fall within these limits are deemed suitable for use in durable pavement materials.

Examples & Analogies

Consider a fitness test where you can only lose a certain percentage of body weight to pass. If you lose more than that, it indicates that your body isn’t handling the stress well. Similarly, the Soundness Test specifies thresholds for weight loss to ensure that the aggregates can handle environmental stress effectively.

Key Concepts

-

Soundness: The ability of aggregates to withstand weathering.

-

Weight Loss Measurement: Key indicator of aggregate durability.

-

Sodium vs Magnesium Sulfate: Different solutions used in testing.

Examples & Applications

An aggregate sample showing less than 12% weight loss after the Soundness Test would be considered durable and suitable for highway pavements.

An aggregate failing the 18% limit in magnesium sulfate is likely unsuitable for use in environments prone to severe weather conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When freeze comes and thaw goes, soundness is what we chose.

Stories

Imagine a brave aggregate fighting through snowy winters, enduring wet and dry periods, only to be weighed at the end to show its strength numbered less than 12.

Memory Tools

S12 for Sodium and M18 for Magnesium — remember the limits!

Acronyms

SWD - Soundness, Wetting, Drying.

Flash Cards

Glossary

- Soundness Test

A test to determine the resistance of aggregates to weathering through freeze-thaw cycles.

- Weight Loss

The measure of the decrease in mass of aggregates after being subjected to the Soundness Test.

- Sodium Sulfate Solution

A solution used in the Soundness Test to evaluate how well aggregates withstand weathering.

- Magnesium Sulfate Solution

An alternative solution for the Soundness Test that assesses aggregate durability.

Reference links

Supplementary resources to enhance your learning experience.