Field Evaluation of Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Field Evaluation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the importance of field evaluations for aggregates used in pavement construction. Why do you think we need to check aggregates in the field, even after lab tests?

Maybe to see how they behave in real-world conditions?

Exactly! The behavior of aggregates in the field can vary from laboratory conditions. We need to ensure they perform well when compacted in actual construction, not just on paper. What do you think could happen if we skip this step?

Pavements might fail prematurely?

Right! Ensuring aggregate quality through field evaluation helps prevent failures. Now, let’s discuss what specific aspects we evaluate.

Methods of Field Evaluation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We primarily use visual inspections and density measurements. Can anyone tell me why cleanliness is critical during visual inspections?

If aggregates are dirty, they might not bond well with the binder?

Exactly! Cleanliness ensures optimal bonding, which affects durability. Now, who can explain the importance of density measurements?

It helps check if the aggregates meet the required specifications for construction?

Correct! Density measurements assure us that the aggregates will perform as expected under load.

Field Compaction Behavior

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into field compaction behavior. Why do you think this is a vital part of aggregate evaluation?

It shows how well they can be compacted in real conditions?

Exactly! The field compaction behavior informs us about the workability and packing efficiency of aggregates. It can affect the overall strength of the pavement as well. Can anyone think of potential problems if aggregates don’t compact well?

There could be voids, and that might lead to water infiltration or weakening of the pavement?

Fantastic point! Compaction helps reduce voids that allow water infiltration, which can cause damage over time.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Field evaluation is essential for assessing aggregate quality beyond laboratory testing. This section outlines methods like visual inspections and field measurements to examine the cleanliness, shape, and compaction behavior of aggregates, which influence pavement performance.

Detailed

Field Evaluation of Aggregates

In pavement construction, aggregates comprise 70–80% of the material, significantly affecting the structure's stability and durability. While laboratory tests are crucial for determining aggregate properties, field evaluations offer practical insights into their behavior in situ. This section highlights the importance of field evaluation and discusses two primary methods: visual inspections and density measurements.

Key Points:

- Visual Inspection: Conducting visual checks allows for assessments of aggregate shape, which impacts pavement performance. Checking for cleanliness helps ensure that aggregates are free from impurities that could weaken the pavement.

- Field Compaction Behavior: Observing how aggregates behave during compaction can provide insights into their workability and performance under load.

- Field Density Measurement: Techniques like the core cutter method or sand replacement method measure field density, helping to confirm that aggregates meet the necessary specifications for density.

The integration of field evaluations with laboratory tests ensures reliable, high-quality aggregates that contribute to the longevity of road infrastructure.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Visual Inspection

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

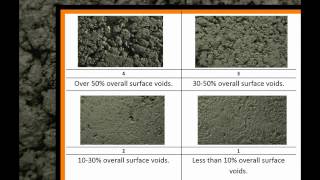

• Visual inspection for shape and cleanliness.

Detailed Explanation

Visual inspection involves checking the aggregates based on their physical appearance. This means observing the shape of the aggregates—whether they are rounded, angular, or flaky—and making sure they are clean, without dust, clay, or organic matter that could affect their performance in road construction.

Examples & Analogies

Think of this like looking at fruits at a grocery store. If an apple is bruised or has too much dirt on it, you might choose not to buy it. Similarly, engineers need to ensure the aggregates are not only in good shape but also clean to ensure the quality of the road construction.

Field Compaction Behavior

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Field compaction behavior.

Detailed Explanation

Field compaction behavior refers to how well the aggregates can be compacted when they are used in actual construction. This is crucial because well-compacted aggregates provide a solid foundation, while poorly compacted aggregates can lead to future problems such as settling or cracking in the pavement.

Examples & Analogies

Imagine packing a suitcase. If you pack clothes tightly, you can fit more in, and they stay in place without shifting. If you don't pack them well, your clothes might end up wrinkled or take up too much space. For aggregates, proper compaction is essential for creating a sturdy road surface.

Field Density Measurement

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Field density measurement using core cutter or sand replacement method.

Detailed Explanation

Field density measurement is the process of assessing the compacted density of the aggregate layer in the field to ensure it meets the required specifications. This can be done using a core cutter, which cuts out a cylinder of the compacted material to measure its weight and volume, or using the sand replacement method, where sand is used to fill the voids in the aggregate layer, and the density is derived from that.

Examples & Analogies

This is akin to checking the firmness of a cake after baking. You might use a toothpick to test if the batter is too moist or if it holds together as it should. Similarly, engineers use these methods to verify that the density of the compacted aggregates is sufficient to support the intended loads and performance of the pavement.

Key Concepts

-

Field Evaluation: Assessing aggregate performance through visual checks and density measurements.

-

Visual Inspection: A crucial method for determining aggregate cleanliness and shape.

-

Density Measurement: Essential for confirming aggregate quality and performance under load.

Examples & Applications

A road construction project where dirty aggregates led to pavement cracking due to poor binder adhesion.

Using the core cutter method to ensure compliance with density standards in a bridge project.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Field checks for aggregate neat and clean, visual and density keep constructions keen.

Stories

In a small town, road workers learned the hard way that ignoring cleanliness in aggregates led to bumpy roads. They started inspecting fields and measuring density, ensuring their town’s roads remained smooth.

Memory Tools

CVD: Cleanliness, Visual Check, Density - remember to check each element in field evaluations!

Acronyms

F.E.A.R

Field Evaluation Assessment Results - keeping aggregates safe for your pavements!

Flash Cards

Glossary

- Aggregate

Granular material used in construction, forming 70-80% of concrete and bituminous pavement volumes.

- Field Evaluation

The assessment of aggregates through visual inspection and field measurements to ensure quality.

- Visual Inspection

A method to check aggregate quality through sight, assessing cleanliness and shape.

- Density Measurement

Techniques used to determine the compactness and density of aggregates in the field.

- Compaction

The process of densifying material by reducing air vacancies within it, critical for pavement stability.

Reference links

Supplementary resources to enhance your learning experience.