Standard Tests on Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding the Crushing Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to start with the Crushing Test. Can anyone tell me why understanding aggregate crushing value is important in construction?

I think it helps to know how much weight they can withstand, right?

Exactly! The crushing value indicates how strong the aggregates are under load. Remember, aggregates with a crushing value less than 30% are suitable for pavement layers. If it's higher, they might break under pressure!

What kind of equipment do we need for this test?

Great question! You'll need a compression testing machine, a cylindrical measure, and a tamping rod. Let's not forget the IS: 2386 (Part IV) standard that outlines our procedure.

Can you recap the steps?

Sure! Fill the aggregate in three layers, tamp each layer, then apply the load and measure what passes through a 2.36 mm sieve. This ensures we accurately assess strength.

So, if we get a value above 30% we should discard those aggregates?

Precisely! You all are catching on. Let's keep it simple: lower crushing value means better for pavement. Remember, CVC is your new acronym for Crushing Value Count!

Alright, to summarize, the Crushing Test helps us understand how aggregates perform under pressure, ensuring our roads are safe and durable.

Exploring the Abrasion Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let's discuss the Abrasion Test. Can anyone tell me why we assess the hardness of aggregates?

I assume it's to see how resistant they are to wear?

Correct! This test is vital for ensuring the aggregates remain intact over time. We use two methods: the Los Angeles Abrasion Test and the Deval Abrasion Test. Can anyone remember the acceptable limits?

For bituminous mixes, it should be less than 35% and for base courses under 40%?

Absolutely right! Now, what equipment do we need for these tests?

We need an LA abrasion machine and some steel balls, correct?

Spot on! When you rotate the sample with the steel balls, any weight loss indicates the aggregate's resistance to wear. Here’s a mnemonic to keep in mind, 'LA stands for Longevity Assurance' for bituminous mixes!

In summary, the Abrasion Test is crucial for assessing the durability of aggregates and thus, their suitability for use in pavement construction.

The Importance of the Impact Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’re looking at the Impact Test. Who can tell me what this test helps determine?

It measures how tough the aggregates are, right?

Exactly! A tough aggregate can handle sudden impacts without breaking. The standard limit is an aggregate impact value of less than 30% for surface courses. What equipment do we require here?

We use an impact testing machine and a cylindrical measure!

Great job! For the procedure, the sample is placed in a cup, and we drop a hammer multiple times from a specific height. Why do we need to weigh the fines below the 2.36 mm sieve?

To see how much is lost due to the impact?

Right again! You’re all getting the hang of this. For memory, let’s remember 'Tough Aggregates Last' or TAL!

To wrap up, the Impact Test helps us understand an aggregate’s ability to sustain loads. This is particularly important in areas with high vehicle traffic.

Shape and Size Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the shape and size of aggregates. Why are these factors important in construction?

I assume they impact the workability and stability of the mix?

Spot on! Shape affects how well aggregates bond with each other and with bitumen. Can anyone name some shapes of aggregates?

Rounded, angular, flaky, and elongated shapes?

Perfect! Now, we have two indices to measure shape: the Flakiness Index and the Elongation Index. Combined, they help evaluate how suitable an aggregate is. What’s the acceptable combined index for bituminous mixes?

It should be less than 35%.

Exactly! To help remember, think 'Shape and Stickiness' for good bonding solutions. Summarizing, understanding aggregate shape and size assists in optimizing concrete mixes for better road conditions.

Chemical and Moisture Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, the chemical properties and moisture content of aggregates play a vital role in their performance. Why do we assess the alkali-aggregate reactivity?

To avoid reactions that can damage the concrete over time?

Exactly! We don’t want unexpected expansions that can cause cracking. Can anyone explain how we test for this?

I remember something about using mortar bars in a NaOH solution?

That's it! Any expansion under 0.1% in 14 days is acceptable. What's the moisture content test's purpose?

To adjust our mix design appropriately?

Right again! Remember, moisture affects the bonding with bitumen. Let’s wrap this session up: understanding the chemical reactions and moisture content helps us design better and more durable pavement.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section provides an overview of standard testing methods utilized to evaluate aggregates used in pavement construction. Key tests include the crushing test, abrasion test, impact test, and several others that measure properties such as strength, toughness, density, and reactivity, ensuring selection of suitable aggregates for various layers of pavement.

Detailed

Standard Tests on Aggregates

Aggregates play a vital role in construction, especially in road infrastructure, forming the bulk of materials used in asphalt and concrete pavements. To ensure their appropriateness, various standardized tests are performed to evaluate their physical and mechanical properties. This section outlines these tests, including the Crushing Test, Abrasion Test, Impact Test, Shape Tests, Specific Gravity and Water Absorption Test, Soundness Test, Stripping Value Test, Alkali-Aggregate Reactivity Test, Deleterious Material Test, Moisture Content Test, and Bulk Density and Voids Test.

- Crushing Test - Assesses the crushing value of aggregates, where values below 30% are deemed suitable for pavement layers.

- Abrasion Test - Measures resistance to wear; acceptable limits for bituminous mixes and base courses are <35% and <40%, respectively.

- Impact Test - Evaluates toughness, with a limit of <30% for surface courses.

- Shape Tests - Include Flakiness Index and Elongation Index to determine particle shape; a combined index can’t exceed 35% for bituminous mixes.

- Specific Gravity and Water Absorption Test - Determines density-related properties and suitable values include specific gravity between 2.6 to 2.9 and water absorption <2%.

- Soundness Test - Tests resistance to weathering through cyclic wetting and drying, with acceptable values of <12% for sodium sulphate and <18% for magnesium sulphate.

- Stripping Value Test - Measures the adhesive properties between bitumen and aggregates, with an acceptable stripping percentage of <25%.

- Alkali-Aggregate Reactivity Test - Detects potential chemical reactivity, ensuring expansion is less than 0.1% in 14 days.

- Deleterious Material Test - Identifies unwanted material, using various methods to ensure aggregate cleanliness.

- Moisture Content Test - Essential for mix design and control, performed through oven-drying methods.

- Bulk Density and Voids Test - Determines compactness and voids in aggregate mass, essential for effective compaction in mix design.

Understanding these tests helps in the selection of appropriate aggregates, influencing the performance and longevity of pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Crushing Test

Chapter 1 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.1 Crushing Test

- Purpose: To determine aggregate crushing value.

- Standard: IS: 2386 (Part IV) – 1963.

- Apparatus: Compression testing machine, cylindrical measure, tamping rod.

- Procedure:

a. Aggregate sample is filled in three layers in a cylindrical mold.

b. Each layer is tamped.

c. Load is applied at a uniform rate.

d. Measure the fraction passing through 2.36 mm sieve. - Result: Aggregates with crushing value <30% are suitable for pavement layers.

Detailed Explanation

The crushing test evaluates how well aggregates can withstand the crushing forces they encounter during service. The test involves filling a cylindrical mold with an aggregate sample in three distinct layers. Each layer is tamped down to ensure accurate measurements. A load is applied uniformly to the sample, simulating the pressure the aggregates would experience in a real-world application. After the load is applied, the test determines the amount of material that passes through a 2.36 mm sieve. If the crushing value is less than 30%, the aggregates are deemed suitable for use in pavement structures.

Examples & Analogies

Think of the crushing test like testing the strength of a cookie. If you lightly press on it and it holds up well, it’s a good cookie. However, if it crumbles easily under pressure, it’s not strong enough for a cookie jar. Similarly, if aggregate crumbles under load, it isn't strong enough for pavement.

Abrasion Test

Chapter 2 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

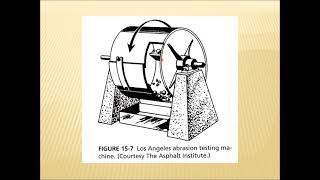

7.3.2 Abrasion Test

- Purpose: To assess the hardness by measuring resistance to wear.

- Methods:

- Los Angeles Abrasion Test – IS: 2386 (Part IV)

- Deval Abrasion Test – IS: 2386 (Part V)

- Apparatus: LA abrasion machine, steel balls.

- Procedure:

a. Sample is rotated with abrasive charge in a drum.

b. Measure the weight loss after a fixed number of revolutions. - Acceptable Limits:

- Bituminous mixes: <35%

- Base courses: <40%

Detailed Explanation

The abrasion test measures how well aggregates can resist wear from friction and mechanical impact. There are two main methods: the Los Angeles Abrasion Test and the Deval Abrasion Test. In both tests, aggregate samples are placed in a rotating drum along with steel balls that act as an abrasive force. As the drum turns, the abrasive charge wears down the aggregate particles. After a specific number of revolutions, the weight of the sample is measured to determine how much material has been lost due to abrasion. Acceptable limits for abrasion loss help ensure the aggregates can withstand the wear they will encounter in real-world conditions.

Examples & Analogies

Imagine a pair of shoes that you wear while walking on dirt roads. If your shoes wear out quickly, they are not suitable for long walks. Similarly, if aggregates lose too much weight in abrasion tests, they won't be durable enough for roads.

Impact Test

Chapter 3 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.3 Impact Test

- Purpose: To determine toughness of aggregates.

- Standard: IS: 2386 (Part IV) – Aggregate Impact Value Test.

- Apparatus: Impact testing machine, cylindrical measure, tamping rod.

- Procedure:

a. Sample is placed in a cup.

b. Hammer is dropped 15 times from a specified height.

c. Fines passing through 2.36 mm sieve are weighed. - Result: Aggregate impact value <30% for surface courses.

Detailed Explanation

The impact test evaluates how well aggregates can resist sudden forces. In this test, an aggregate sample is placed in a cup that is subjected to a series of impacts from a dropping hammer. The sample is hit 15 times from a predetermined height. After the strikes, the smaller particles that break off and pass through a 2.36 mm sieve are collected and weighed. If the total weight of these particles is less than 30% of the original sample, the aggregates are considered tough enough for use in surface courses of pavements.

Examples & Analogies

Think of the impact test like testing a piñata. If it breaks easily, it likely won't last during a party. But if it can withstand a lot of hits without falling apart, it's tough and durable. Similarly, aggregates need to be able to handle sudden loads without breaking.

Shape Tests

Chapter 4 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.4 Shape Tests

- Flakiness Index (FI) – IS: 2386 (Part I)

- Measures the percentage of flaky particles (thickness < 0.6 × mean sieve size).

- Elongation Index (EI) – IS: 2386 (Part I)

- Measures the percentage of elongated particles (length > 1.8 × mean sieve size).

- Combined Index: Should generally be <35% for bituminous mixes.

Detailed Explanation

Shape tests assess the physical shapes of aggregate particles, as the proportions of flaky and elongated particles can affect the performance of asphalt mixes. The Flakiness Index measures the percentage of thin, flat particles while the Elongation Index measures long and narrow particles. These indices help identify how well the aggregates will compact and interlock in a mix. A combined index less than 35% for bituminous mixes is typically acceptable to ensure good performance.

Examples & Analogies

Consider a puzzle made up of pieces that fit together. If some pieces are very thin or oddly shaped, it becomes difficult to create a firm picture. Just like having the right shape of puzzle pieces is essential, having the right shape of aggregates ensures a smooth and stable pavement.

Specific Gravity and Water Absorption Test

Chapter 5 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.5 Specific Gravity and Water Absorption Test

- Standard: IS: 2386 (Part III).

- Purpose: Determines density-related properties.

- Types of Specific Gravity:

- Apparent specific gravity.

- Bulk specific gravity (oven-dry or saturated surface dry).

- Water Absorption: Affects bitumen adhesion and moisture susceptibility.

- Acceptable Values:

- Specific Gravity: 2.6 – 2.9

- Water Absorption: <2%

Detailed Explanation

This test determines the specific gravity of aggregates, which indicates how dense they are compared to water. Two types of specific gravity are measured: apparent specific gravity, which considers all spaces within the material, and bulk specific gravity, which measures the weight of the aggregate when saturated or oven-dried. Additionally, the water absorption capacity is crucial as it affects how aggregates will interact with bitumen, which is essential in paving mixes. Acceptable ranges for specific gravity and water absorption help identify the suitability of aggregates.

Examples & Analogies

Think of a sponge and a rock. The sponge absorbs water because it has many spaces in it, while the rock remains dry. When choosing materials for a road, knowing how much water aggregates absorb, like understanding the properties of sponges versus rocks, helps predict how they will behave in wet conditions.

Soundness Test

Chapter 6 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.6 Soundness Test

- Purpose: Assess resistance to weathering, particularly freeze-thaw.

- Standard: IS: 2386 (Part V).

- Procedure:

a. Samples are subjected to repeated cycles of wetting and drying in sodium or magnesium sulphate solution.

b. Weight loss is measured. - Acceptable Values:

- <12% for sodium sulphate

- <18% for magnesium sulphate

Detailed Explanation

The soundness test evaluates how aggregates resist weathering effects, particularly from cycles of freezing and thawing. In the test, aggregate samples are subjected to repeated wetting and drying in solutions of sodium or magnesium sulfate. Then, the change in weight is measured to assess durability under weather conditions. Acceptable weight loss percentages indicate that the aggregates can withstand harsh environmental conditions.

Examples & Analogies

Consider how a car battery might fail in extreme cold and heat. If it's well-built, it remains functional; if not, it deteriorates quickly. Similarly, aggregates must be tough to handle freezing and thawing without breaking down, as they form the foundation of our roads.

Stripping Value Test

Chapter 7 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.7 Stripping Value Test

- Purpose: Evaluates adhesive property between bitumen and aggregates.

- Apparatus: Beaker, hot plate.

- Procedure:

a. Bitumen-coated aggregate samples are boiled in water.

b. Visual inspection for stripping of bitumen film. - Result: <25% stripping is acceptable.

Detailed Explanation

The stripping value test assesses how well bitumen adheres to aggregates, which is crucial for paving performance. In this test, bitumen-coated aggregates are boiled in water to simulate conditions they might face in the field. After boiling, visual inspection is performed to assess how much of the bitumen has separated from the aggregates. A stripping level of less than 25% indicates good adhesion and suitability for bituminous mixes.

Examples & Analogies

Imagine a sticker being placed on a wet surface—it might not stick well. Just like that sticker needs a dry surface to adhere, bitumen needs to bond properly with aggregates; if it doesn’t, the road can deteriorate.

Alkali-Aggregate Reactivity Test

Chapter 8 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.8 Alkali-Aggregate Reactivity Test

- Purpose: To detect potential chemical reactivity with cement in concrete.

- Standard: IS: 2386 (Part VII).

- Types:

- Alkali-silica reaction (ASR)

- Alkali-carbonate reaction (ACR)

- Procedure: Mortar bars are tested for expansion in NaOH solution.

- Acceptable Limit: Expansion <0.1% in 14 days.

Detailed Explanation

This test checks for chemical reactions between alkalis in cement and certain aggregate types, which can lead to expansion and cracking in concrete over time. The test includes two types of reactions: the alkali-silica reaction and the alkali-carbonate reaction. Mortar bars made with the aggregates are submerged in a sodium hydroxide solution, and their expansion is measured over 14 days. An acceptable limit of less than 0.1% expansion suggests minimal reactivity, indicating suitable aggregates.

Examples & Analogies

Think of how some foods can spoil when mixed together—like vinegar and baking soda create a reaction. Similarly, when certain aggregates and cement mix, if they react negatively, it creates problems for the concrete. Testing helps ensure we prevent such bad combinations in our roads.

Deleterious Material Test

Chapter 9 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.9 Deleterious Material Test

- Purpose: Detects the presence of unwanted materials (clay, silt, organic matter).

- Methods:

- Clay Lumps and Friable Particles Test

- Organic Impurities Test (using NaOH solution)

- Lightweight Particles Test

Detailed Explanation

This test is designed to identify any unwanted materials that could compromise the performance of aggregates. Methods vary, but common tests include checking for clay lumps, organic impurities, and lightweight particles that could lead to weakness in concrete and asphalt. By detecting these materials, we help ensure that only quality aggregates are used in construction.

Examples & Analogies

Imagine cooking with ingredients that include spoiled items; they could ruin your dish. Similarly, removing unwanted materials from aggregates ensures that the final 'recipe' for road construction is high-quality and durable.

Moisture Content Test

Chapter 10 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.10 Moisture Content Test

- Purpose: Determines moisture content for mix design adjustment.

- Standard: IS: 2386 (Part III).

- Method: Oven-drying or moisture meters.

- Use: Essential for volumetric mix design and compaction control.

Detailed Explanation

The moisture content test determines how much water is present in the aggregate material, which affects the mix design used for asphalt or concrete. This test is crucial for ensuring that the right proportions of materials are used, to achieve optimal compaction and longevity of the pavement. Techniques for measuring moisture include oven-drying the sample or utilizing moisture meters.

Examples & Analogies

Just like when baking bread, the amount of water you add affects the dough's texture and final product. Similarly, having the right moisture content in aggregate helps ensure that roads are built effectively.

Bulk Density and Voids

Chapter 11 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

7.3.11 Bulk Density and Voids

- Purpose: Determines the compactness and voids in aggregate mass.

- Standard: IS: 2386 (Part III).

- Significance: Used in mix design to calculate voids and optimize compaction.

Detailed Explanation

The bulk density and voids test measures how densely aggregates are packed and identifies any void spaces in the aggregate mass. This information is important for mix design, as it helps engineers calculate how much binder material, like asphalt or concrete, is necessary to fill those voids and achieve the desired compactness. Knowing the density also aids in optimizing the material mixture for durability and performance.

Examples & Analogies

Think of packing a suitcase; if you leave spaces between items, you can fit in more clothes. However, if you pack it tightly with no gaps, it prevents shifting during travel. Similarly, understanding the density and voids in aggregates ensures the right balance for a strong road.

Key Concepts

-

Crushing Test: Measures the strength of aggregates under load.

-

Abrasion Test: Assesses the resistance of aggregates to wear and tear.

-

Impact Test: Evaluates the toughness and resilience of aggregates during sudden loads.

-

Flakiness and Elongation Indices: Measure the shapes of aggregates affecting workability.

-

Specific Gravity: Indicates the density-related properties of aggregates.

-

Water Absorption: Determines the water absorption capacity affecting mix design.

-

Soundness Test: Evaluates resistance of aggregates to weathering.

-

Stripping Value: Assesses the bond between bitumen and aggregates.

Examples & Applications

Example of a Crushing Test: A sample aggregate with a crushing value of 28% is found suitable for road base use.

Example of an Abrasion Test: An aggregate sample loses 30% of its weight in the Los Angeles test, indicating it's fit for a bituminous mix.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When evaluating aggregate, don't forget the test, Crushing value ensures it's strong and best!

Stories

Picture a road built on aggregates. Each test ensures that every stone is tough and durable, capable of holding up against traffic and weather, just like a family standing strong through storms.

Memory Tools

Remember the acronym CRUSH for testing:

Acronyms

BILLI

Bitumen adhesion measures resistance to stripping

understand moisture content

Long-lasting compaction

Ideal shape indices

and the importance of the soundness test.

Flash Cards

Glossary

- Crushing Test

A test that determines the crushing value of aggregates to assess their strength under applied loads.

- Abrasion Test

A test that measures the resistance of aggregates to wear and tear, assessing their hardness.

- Impact Test

A test that measures the toughness of aggregates by determining the amount of fines generated from impact.

- Flakiness Index

A measure of the percentage of flaky particles in an aggregate sample.

- Elongation Index

A measure of the percentage of elongated particles in an aggregate sample.

- Specific Gravity

A measure that indicates the density of aggregates in relation to water.

- Water Absorption

The percentage of water an aggregate can absorb, affecting its bonding properties.

- Soundness Test

A test that evaluates the resistance of aggregates to weathering effects.

- Stripping Value Test

A test that evaluates the adhesion properties of aggregates in relation to bitumen.

- AlkaliAggregate Reactivity

Chemical reactions that can occur between alkalis in cement and reactive silica in aggregates, potentially damaging concrete.

Reference links

Supplementary resources to enhance your learning experience.