Selection Criteria for Aggregates in Pavement Construction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Aggregate Selection Criteria

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll begin discussing the selection criteria for aggregates in pavement construction. Can anyone tell me why selecting the right aggregates is important?

I think it's because they affect how strong and durable the pavement will be.

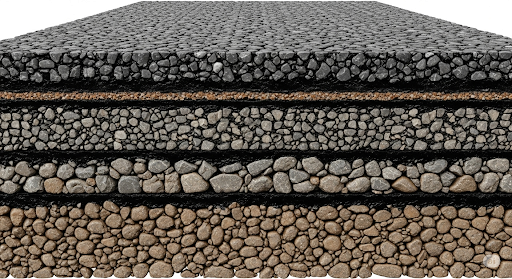

Exactly! Aggregates make up about 70-80% of the volume of concrete and asphalt mixes, impacting not just strength but also durability and resistance to wear. Now, can anyone name the different layers we consider when using aggregates?

I believe there are surface, base, and sub-base courses.

That's correct! Each layer requires different criteria for aggregate selection. For example, what do you think the strengths should be for the surface course?

It should be tough and have high strength?

Yes! The surface course should ideally have high strength and an angular shape with an abrasion value less than 30-35%. Let's remember this acronym 'SAB' for Surface, Angular, and below 30% Abrasion. Good job!

Details of Aggregate Requirements for Each Layer

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the specific requirements for the base course. Who can summarize what we need for aggregates here?

They need to have medium to high strength and an angular shape, and the abrasion value should be less than 40%.

Right! And what about the sub-base course? Its criteria differs a bit.

The sub-base can have moderate strength and be sub-angular with up to 50% abrasion value?

Exactly! Learning these differences is important for optimal pavement performance. Why do you think the shapes of the aggregates matter?

I guess it affects how well they bond together?

Correct! Angular aggregates fit together better, enhancing stability. Always remember this connection. Great insights today!

Importance of Clean and Dry Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

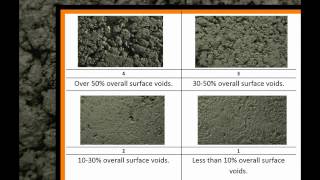

Now, let’s talk about bituminous layers. What is a critical aspect of aggregates here?

They have to be clean and dry, right?

Yes! Clean aggregates are crucial for proper adhesion with bitumen. What do we mean by 'low stripping' in this context?

The amount of bitumen that separates from the aggregates?

Exactly! We want it to be under 30%. If you remember 'Clean, Dry, Low Stripping' – CDLS – it can help you recall the importance of aggregates in bituminous layers. How does this knowledge apply in real construction scenarios?

It could help prevent layers from failing early due to poor bonding.

Great application! Proper selection fundamentally supports the success of pavement structures. Excellent discussion!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section provides a detailed classification of aggregates required for different pavement layers, emphasizing the importance of their strength, abrasion resistance, and shape. It specifies the acceptable limits for aggregates in surface courses, base courses, and sub-base courses.

Detailed

Selection Criteria for Aggregates in Pavement Construction

Aggregates are crucial for effective pavement construction, and their selection must consider various factors to ensure structural integrity and longevity. This section elaborates on the selection criteria based on the pavement layer classification:

- Surface Course: Materials need to have a high strength, be angular in shape, and maintain an abrasion value of less than 30-35%. This helps ensure a durable top layer that can withstand traffic loads and weather effects.

- Base Course: Requires a medium to high strength, preferably with an angular shape, with an allowable maximum abrasion value of 40%. This layer is critical for distributing loads to lower structural layers.

- Sub-Base Course: Here, aggregates can have moderate strength and can be sub-angular in shape, with a maximum abrasion value of less than 50%. This layer provides additional support to the pavement's structure.

- Bituminous Layers: On these layers, high adhesion properties are essential, and aggregates must be clean and dry to ensure proper bonding with bitumen. An acceptable stripping value under 30% is necessary to prevent delamination of the layers.

By adhering to these criteria, the performance and durability of pavement structures can be optimized.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Strength Requirements for Pavement Layers

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Strength Max. Abrasion Layer Requirements Shape Value

Surface Course High Angular <30–35%

Detailed Explanation

In pavement construction, the surface course requires high strength to withstand significant traffic loads. The aggregates used in this layer must be angular in shape, as angular aggregates provide better interlocking and structural integrity. Furthermore, the maximum abrasion value must be less than 30-35%, indicating that the aggregates should not wear down too quickly when subjected to friction and wear from traffic.

Examples & Analogies

Imagine trying to build a sturdy tower using different types of bricks. If you use soft, round pebbles, they may roll and not hold together well under pressure. However, if you use sharp-edged stones that fit tightly together, just like angular aggregates in a pavement, your tower will be much more stable and durable.

Base Course Requirements

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Base Course Medium–High Angular <40%

Detailed Explanation

The base course of a pavement also requires aggregates that are medium to high in strength. Similar to the surface course, these aggregates should be angular, which helps in achieving necessary support for the layers above. The maximum abrasion value in this case should be less than 40%, allowing for adequate resistance to wear while ensuring the layer remains stable under load.

Examples & Analogies

Think of the base course as the foundation of a house. Just like how you would want strong, solid blocks for the foundation to support the weight of the entire house, the base course aggregates need to be strong and angular to effectively support the surface layer that will be laid on top.

Sub-Base Course Characteristics

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Sub-Base Course Moderate Sub-angular <50%

Detailed Explanation

For the sub-base course, aggregates are required to have moderate strength and should preferably be sub-angular rather than fully angular. This provides a balance between workability and stability. The maximum abrasion value allowable for the sub-base is less than 50%, indicating a slightly higher tolerance for wear compared to the surface and base courses, as this layer is not in direct contact with the heaviest traffic.

Examples & Analogies

Imagine the sub-base course as a mattress under the sheets of a bed. It doesn't need to be as firm as the mattress you lie on, but it still needs to provide some support. Using moderate-strength, sub-angular aggregates is similar to choosing a soft, supportive mattress that complements the comfort of the sheets on top.

Bituminous Layer Considerations

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous High adhesion, Clean, dry <30% layers low stripping

Detailed Explanation

In a bituminous layer, aggregates must ensure high adhesion with the bitumen. This means the aggregates should be clean and dry, helping to achieve better bonding with the adhesive material. Stripping value must be low (below 30%), which ensures that the bitumen does not peel away from the aggregates when exposed to moisture, thereby reducing the risk of pavement failure.

Examples & Analogies

Think of the bituminous layer as a layer of glue used to attach tiles to a surface. If the tiles (aggregates) are dirty or wet, the glue won’t stick properly, and the tiles might peel off. Just like how using clean and dry tiles ensures a strong bond with the glue, using clean and dry aggregates ensures the bituminous layer stays intact on the road.

Key Concepts

-

Aggregate Selection: The process of choosing appropriate aggregates based on layer requirements.

-

Layer Specificity: Different layers of pavements require different properties in aggregates.

-

Cleanliness Requirement: Aggregates in bituminous layers must be clean and dry to prevent stripping.

Examples & Applications

In surface courses, angular aggregates with a strength requirement of less than 30-35% abrasion value are preferred to ensure durability under heavy traffic.

In a base course, aggregates must have a medium to high strength and must not exceed a 40% abrasion value to effectively distribute loads.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For a pavement to behave, strength and shape we must save.

Stories

Once upon a time, there were three layers: Surface, Base, and Sub-base. Each layer had its own unique needs, like strength and shape, to ensure they lived happily under the weight of traffic.

Memory Tools

SAB for Surface, Angular, and below 30% Abrasion.

Acronyms

CDLS - Clean, Dry, Low Stripping, crucial for bituminous layers.

Flash Cards

Glossary

- Surface Course

The top layer of the pavement structure, designed to resist traffic and weather effects.

- Base Course

The layer under the surface course that provides structural support.

- SubBase Course

A layer providing additional support beneath the base course, often comprised of coarser materials.

- Angular Shape

A particle shape that enhances interlocking and stability when used in mixes.

- Abrasion Value

A measure of an aggregate's resistance to wear and degradation.

Reference links

Supplementary resources to enhance your learning experience.