Dynamic Modeling of Manipulators

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Key Parameters of Robotic Links

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will discuss the important parameters that define each link of a robotic manipulator. Can anyone tell me what some of those parameters might be?

Is mass one of the parameters?

Excellent! Yes, link mass is a critical parameter. It helps us understand how the weight of each link affects the manipulator's dynamics. What else do we need to consider?

Length of the link?

That's correct! The length of the link influences its reach and the overall kinematic structure of the manipulator. How about the position of the mass?

The center of mass?

Yes, the center of mass is crucial because it affects how forces like gravity impact the manipulator. Lastly, we cannot forget the inertia tensor. Can anyone summarize why it’s significant?

It shows how the mass is distributed and affects how the robot responds to rotational forces.

Exactly! The inertia tensor is vital for understanding the robot's resistance to changes in motion.

To summarize, we've discussed mass, length, the center of mass, and the inertia tensor as key parameters for dynamic modeling. Understanding these helps in accurate simulations of robotic dynamics.

Modeling Approaches

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know the parameters, let’s talk about two approaches to dynamic modeling: symbolic modeling and numerical modeling. Can anyone explain what symbolic modeling is?

Is that when we use software to create mathematical representations?

Correct! Symbolic modeling uses tools like MATLAB to create equations that represent the dynamics symbolically, which is great for deriving general solutions. What about numerical modeling?

I think that's when we use actual parameters to simulate the behavior in real time?

Absolutely! Numerical modeling helps us perform quick computations for simulations, useful for real-time applications. Would anyone like to share examples of when to use each type?

We might use symbolic modeling for design purposes, and numerical modeling for during control when running a robot.

Excellent observation! Both methods have their applications, and understanding when to use each is crucial in robotics.

To wrap up, we've looked at symbolic versus numerical modeling. Remember, the choice depends on the context of use, whether for design or for real-time processing.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Dynamic modeling of manipulators focuses on representing each robotic link using key parameters such as mass, length, center of mass, and inertia tensor. The section contrasts symbolic modeling using tools like MATLAB with numerical modeling involving real-time computations, emphasizing the significance of these methods in dynamic analysis.

Detailed

Dynamic Modeling of Manipulators

In this section, we delve into the critical parameters required for modeling each link of a robotic manipulator. The key factors include:

- Link Mass: Represents the weight distribution of the link.

- Length: The dimensions that affect the kinematic and dynamic capabilities.

- Center of Mass: The average location of the mass distribution that is crucial for calculating gravitational effects and rotational inertia.

- Inertia Tensor: A mathematical representation that describes how the mass is distributed throughout the body, influencing the resistance against angular acceleration.

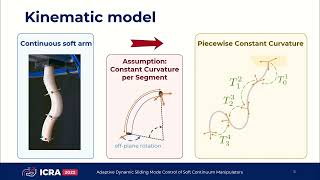

Two principal approaches are utilized for dynamic modeling:

1. Symbolic Modeling: This method leverages software tools, such as the MATLAB Symbolic Toolbox, allowing for the generation of symbolic representations of the manipulator's dynamics.

2. Numerical Modeling: Contrarily, this approach involves simulating the dynamics of the manipulator in real-time, utilizing specific parameters for quick computations.

Understanding these modeling techniques and the parameters involved is vital for implementing effective dynamic analysis and control strategies in robotics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Modeling Components of Robot Links

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Each robotic link is modeled using:

- Link mass

- Length

- Center of mass

- Inertia tensor

Detailed Explanation

In robotics, each link of a manipulator, which is basically any mechanical arm or jointed structure, needs to be defined using specific properties. The 'link mass' indicates how much each part weighs, which affects how much force is needed to move it. The 'length' refers to how long each link is and is critical for determining how far the robot can reach. 'Center of mass' is an important point that represents where the mass of the link is concentrated, impacting balance and stability. Lastly, the 'inertia tensor' is a mathematical description of how the mass is distributed relative to the axis of rotation; it helps in understanding how the link will rotate when force is applied.

Examples & Analogies

Think of a seesaw in a playground. If you have a heavy child on one side (representing link mass) and a light one on the other side, the seesaw will tip to the heavier side. The length of the seesaw affects how high each side goes. If you placed the heavier child further away from the pivot point (center of mass), it may tip the seesaw even more. This scenario helps illustrate how mass, length, and center of mass work together in a physical system.

Two Modeling Approaches

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Two modeling approaches:

1. Symbolic Modeling: Using software tools (e.g., MATLAB Symbolic Toolbox)

2. Numerical Modeling: Real-time computations using parameters

Detailed Explanation

There are two main approaches when modeling robotic manipulators. The first is 'Symbolic Modeling', which involves defining the robot's mathematical model analytically, often using special software like MATLAB's Symbolic Toolbox. This approach lets engineers manipulate the equations symbolically, which can be advantageous for deriving general solutions. The second approach is 'Numerical Modeling'. This involves using actual numerical values to compute motions and forces in real-time. This method is often used in situations requiring immediate responses, like in active robots, where it can quickly process the required calculations for movement and forces as they happen.

Examples & Analogies

Consider a recipe for baking a cake. Symbolic modeling is like writing down the recipe in general terms, such as 'use sugar, flour, and eggs', which lets you adapt it for any size cake (just as symbolic modeling can adapt to various parameters of a robot). Meanwhile, numerical modeling is like measuring out actual quantities of each ingredient to bake one specific cake. This allows you to see how everything interacts when combined in real-time, similar to a robot calculating forces and movements as they occur.

Key Concepts

-

Link Mass: The weight of a specific link in a robotic manipulator that influences its motion characteristics.

-

Length: The measurement determining how far a link can reach, contributing to the manipulator's overall length.

-

Center of Mass: The balance point of a mass which affects motion and behavior under forces like gravity.

-

Inertia Tensor: A property that describes how mass is distributed within a link, influencing rotational motion.

-

Symbolic Modeling: A method using software to create algebraic representations for the dynamics of robots.

-

Numerical Modeling: A technique used for real-time simulation of dynamic behavior based on actual parameters.

Examples & Applications

Dynamic modeling is used in robot simulations to predict exact movements in environments, such as in industrial manufacturing robots.

Using numerical modeling, engineers can quickly modify parameters to see how changes affect robotic performance during development.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When modeling robots, do it right, mass, length, and center in sight.

Stories

Imagine a robot arm reaching for a star, it needs to know its length and mass from afar. The center of mass keeps it stable on its way, while the inertia tensor guides its play.

Memory Tools

To remember the parameters: M, L, C, I - Mass, Length, Center of mass, Inertia. Just think of 'Mighty Lifting Center Inertia'!

Acronyms

For the modeling types, S for Symbolic and N for Numerical - 'SN Modeling'.

Flash Cards

Glossary

- Link Mass

The weight of a specific link in a robotic manipulator that affects its dynamics.

- Length

The distance measurement of a robotic link which affects reachability and kinematics.

- Center of Mass

The average position of mass distribution in a link, important for gravitational calculations.

- Inertia Tensor

A mathematical representation that describes how mass is distributed in a body, influencing moment of inertia.

- Symbolic Modeling

The use of software tools to represent system dynamics with mathematical expressions.

- Numerical Modeling

Real-time computational modeling that requires specific parameters for simulations.

Reference links

Supplementary resources to enhance your learning experience.