DFM Tools

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to DFM Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about how EDA tools support DFM. Why do you think using tools is critical in the design process?

I think they help automate checks that would take forever to do by hand.

Exactly! Tools like Cadence Allegro help streamline DFM analysis by minimizing design errors before fabrication. Can anyone name another tool used for DFM?

Mentor Graphics Calibre!

Correct! Calibre focuses on layout checking and enhancing yield. Remember the acronym 'CAD' for Computer-Aided Design tools also applies here. Why do you think yield improvement is crucial?

Because a higher yield means less waste and more profit!

Exactly right! A great example is that for every defective chip, that's a lost opportunity. Let's summarize what we learned: The use of EDA tools like Cadence Allegro and Mentor Graphics Calibre is critical for effective DFM.

Specific EDA Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore individual tools. Cadence Allegro not only performs DFM analysis but also assists with layout optimization. Can someone describe why layout optimization is essential?

It reduces potential defects during manufacturing.

Exactly! And what about Mentor Graphics Calibre? How does it enhance manufacturability?

It checks the layout for manufacturability and identifies errors.

Perfect! And Synopsys IC Validator? Who can explain its role?

It detects DFM issues related to layout, right?

That's correct! Let's recap: Cadence Allegro aids in analysis; Mentor Graphics Calibre checks layouts, and Synopsys IC Validator addresses layout-related DFM issues.

Integration of DFM Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Integration of DFM tools is crucial for smooth workflows. Can anyone explain why simultaneous use of multiple tools might be beneficial?

It allows for cross-checking between tools to ensure no step is missed.

Exactly! When tools like Cadence Allegro and Mentor Graphics Calibre are used together, they can cover more ground. Can anyone think of a potential challenge to this integration?

Sometimes tools might not communicate well with each other, which could create inefficiencies.

Great point! Overcoming tool incompatibilities is essential. Remember, integrating DFM tools enhances manufacturability and reduces defects. Let's summarize today’s lessons: Tools are vital for analysis, layout checking, and integration helps prevent errors.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the key EDA tools used for DFM, including Cadence Allegro, Mentor Graphics Calibre, and Synopsys IC Validator. Each tool plays a vital role in optimizing designs for manufacturability, ensuring compliance with fabrication requirements, and enhancing yield.

Detailed

In the realm of VLSI design, Design for Manufacturability (DFM) entails ensuring that the design can be easily and efficiently manufactured. This is where Electronic Design Automation (EDA) tools come into play. Tools such as Cadence Allegro help with DFM analysis and optimization by minimizing design errors. Mentor Graphics Calibre focuses on layout checking and enhancing yield, while Synopsys IC Validator addresses layout-related DFM concerns, including interconnects and process variations. The integration of these tools streamlines the design process, enabling designers to achieve effective manufacturability and better overall performance of semiconductor products.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to DFM Tools

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

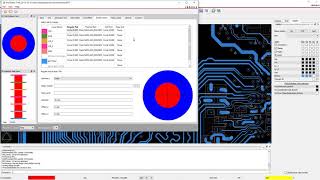

EDA tools assist with DFM to ensure that the design is optimized for manufacturing:

Detailed Explanation

In the context of Design for Manufacturability (DFM), Electronic Design Automation (EDA) tools play a crucial role. These tools are designed to aid engineers and designers in optimizing their designs to ensure they can be manufactured effectively and efficiently. They help identify potential issues in designs and suggest optimizations to improve manufacturability.

Examples & Analogies

Think of EDA tools like a quality control system in a production line. Just as quality control checks products to ensure they meet certain standards before they go to customers, EDA tools check the chip design and suggest changes so that the end product can be manufactured with minimal issues.

Cadence Allegro

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Cadence Allegro: Allegro provides tools for DFM analysis and optimization, helping to minimize design errors and improve manufacturability.

Detailed Explanation

Cadence Allegro is a popular EDA tool that focuses on the analysis and optimization of designs for manufacturability. It helps designers identify design errors early in the process, which can prevent costly manufacturing issues. By using Allegro, designers can refine their layouts and ensure that they adhere to the manufacturing constraints, thus increasing the chances of producing a defect-free chip.

Examples & Analogies

Imagine you are cooking a recipe. If you have a kitchen tool that helps you measure ingredients precisely, you are less likely to end up with a dish that doesn’t turn out right. Similarly, Cadence Allegro helps designers accurately tweak their designs to get them just right for manufacturing.

Mentor Graphics Calibre

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Mentor Graphics Calibre: Calibre offers DFM tools that focus on checking and optimizing the layout for manufacturability and yield enhancement.

Detailed Explanation

Mentor Graphics' Calibre tool is extensively used in DFM processes to ensure that designs are not only ready for manufacturing but also optimized for yield enhancement. It checks the layout for any design rule violations that could lead to defects during chip production. By catching these issues early, it helps designers make necessary adjustments before the manufacturing process begins.

Examples & Analogies

Consider Calibre like a safety net for a tightrope walker. The walker prepares to cross a high wire, and the safety net ensures that if they fall, they are protected. In the same way, DFM tools like Calibre catch potential design flaws before they can lead to failures in manufacturing.

Synopsys IC Validator

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Synopsys IC Validator: This tool helps detect and fix DFM issues related to layout, interconnects, and process variations.

Detailed Explanation

Synopsys IC Validator is another critical tool used in the DFM space. It focuses on detecting layout and interconnect issues that can arise during the manufacturing of a chip. The tool helps engineers identify variations in the manufacturing process that could potentially affect the chip’s performance. By addressing these DFM issues, designers can further enhance yield and improve the reliability of their designs.

Examples & Analogies

Think of Synopsys IC Validator as a meticulous editor for a writer's draft. Just as an editor reviews a manuscript to catch inconsistencies or errors that could confuse readers, this tool reviews chip layouts to identify potential manufacturing issues that could cause problems down the line.

Key Concepts

-

Design for Manufacturability (DFM): Techniques applied within the design process to make chip manufacturing efficient.

-

EDA Tools: Software utilized to assist designers in analyzing and optimizing designs for manufacturability.

-

Yield Improvement: The objective of minimizing defects to maximize the quantity of functional chips produced.

Examples & Applications

Using Cadence Allegro, designers can check their layouts for compliance with manufacturing rules to prevent defects.

Mentor Graphics Calibre can effectively reduce layout errors that would otherwise lead to manufacturing failures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

CAD for chips, make designs fit, DFM tools do the clever bit.

Stories

Imagine a team of engineers using Cadence Allegro to sculpt a masterpiece of silicon, ensuring a flawless design while Mentor Graphics Calibre acts as a vigilant guardian against errors.

Memory Tools

C-A-M for remembering Cadence Allegro, Calibre, and Maximizing yield.

Acronyms

DFM

Design For Manufacturability - Remember this to keep manufacturability in focus.

Flash Cards

Glossary

- Cadence Allegro

An EDA tool that provides DFM analysis and optimization, helping to minimize design errors.

- Mentor Graphics Calibre

An EDA tool focused on layout checking and yield enhancement in VLSI design.

- Synopsys IC Validator

A tool used to detect and fix DFM issues related to layout and interconnects.

Reference links

Supplementary resources to enhance your learning experience.