Conclusion

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of DFT and DFM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to conclude our discussion of DFT and DFM by talking about why these principles are so important. Can anyone summarize what DFT aims to achieve?

DFT helps reduce testing costs and ensures functionality!

Exactly! DFT minimizes test costs by providing efficient testing methods. What about DFM? What does it focus on?

DFM ensures that a design is optimized for manufacturing!

Right again! It aims to reduce manufacturing costs and improve yield. Remember, DFT and DFM work together to enhance the overall chip production process. Let's recall the acronym DFT— 'Design for Testability'—to remember what it's all about!

Does that mean they should always be integrated during the design phase?

Exactly! Integrating DFT and DFM from the beginning of the design process ensures that the final product can be thoroughly tested and manufactured efficiently. This leads to high-performance and reliable semiconductor devices.

To summarize, we learned that DFT minimizes test costs and ensures functionality while DFM optimizes designs for manufacturing, improving yield and reducing costs. Great job today!

Techniques of DFT and DFM

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into the specific techniques used in DFT and DFM. Can someone name a common DFT technique?

Scan chain insertion!

Spot on! Scan chain insertion allows access to internal signals for testing. How about a DFM technique?

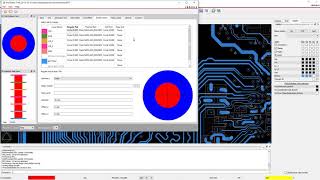

Design Rule Checking (DRC) helps ensure that the design fits the manufacturing process.

Right! DRC is crucial in preventing defects during fabrication. Can you all see how these techniques, both from DFT and DFM, contribute to improving yield?

Yes! They help catch problems early and optimize designs!

Exactly! To keep these techniques in mind, think of DFT techniques as 'testing aids' and DFM techniques as 'manufacturing facilitators'.

In conclusion, integrating DFT techniques like scan insertion with DFM techniques such as DRC yields better-performance chips.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In the conclusion of this chapter, the intertwined significance of Design for Testability (DFT) and Design for Manufacturability (DFM) is emphasized. By implementing various DFT techniques and DFM strategies, designers can enhance the quality and manufacturability of VLSI chips, ultimately leading to better performance and reliability.

Detailed

Conclusion

In the field of modern Very Large Scale Integration (VLSI) design, the principles of Design for Testability (DFT) and Design for Manufacturability (DFM) play a pivotal role in ensuring that semiconductor products are both reliable and efficient. DFT incorporates techniques like scan insertion, Built-In Self-Test (BIST), and JTAG, which facilitate effective testing procedures throughout the manufacturing process. On the other hand, DFM emphasizes design strategies such as design rule checking (DRC), process variation management, and layout optimization to enhance manufacturability.

The integration of DFT and DFM concepts early in the design process significantly benefits yield optimization, quality enhancement, and cost reduction in chip production. Together, DFT and DFM pave the way for delivering high-performance, reliable semiconductor products in shorter time frames, ultimately achieving the industry's needs for efficiency and excellence.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of DFT and DFM

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Design for Testability (DFT) and Design for Manufacturability (DFM) are critical principles that ensure the final VLSI design is both testable and manufacturable.

Detailed Explanation

This chunk highlights the significance of combining DFT and DFM in the design process. DFT focuses on making sure that the design of a chip can be easily tested for faults, while DFM aims to ensure that the chip can be manufactured efficiently and without defects. Together, these principles ensure that the semiconductor products meet quality standards and can be produced in a cost-effective manner.

Examples & Analogies

Think of DFT as making sure that a new car model is equipped with easy access points for mechanics to conduct inspections and tests, while DFM is like designing the car so that it can be built on an assembly line without hiccups. Just as a well-designed car can be both tested easily and manufactured efficiently, a well-designed chip follows these principles to ensure performance and reliability.

Techniques Used in DFT and DFM

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By incorporating DFT techniques such as scan insertion, BIST, and JTAG, and applying DFM techniques like DRC, layout optimization, and process variation management, designers can improve the quality, yield, and cost-effectiveness of chip production.

Detailed Explanation

This chunk outlines specific techniques used in DFT and DFM. DFT techniques like scan insertion help ensure that internal chip signals can be easily observed and tested. BIST allows chips to perform self-tests, and JTAG facilitates testing connections. On the DFM side, tools like Design Rule Checking (DRC) and layout optimization help eliminate potential production errors. These techniques work together to enhance the overall effectiveness and efficiency of chip manufacturing.

Examples & Analogies

Imagine you are baking cookies. Using a recipe (DFT techniques) that provides clear instructions for whether the cookies are baked fully, along with a method for checking (like using a toothpick) ensures that the cookies turn out right every time. Meanwhile, using high-quality ingredients and ensuring you have the right baking tools (DFM techniques) makes sure that the baking process goes smoothly and yields perfect cookies. Both the right recipe and good ingredients are vital for successful baking.

Integration for Success

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Integrating both principles into the design process is essential for achieving high-performance, reliable, and efficiently manufactured semiconductor products.

Detailed Explanation

This chunk emphasizes the importance of integrating DFT and DFM throughout the design process. Considering both aspects helps ensure that the final design doesn’t just perform well but can also be manufactured without problems. A successful integration means that chip designs are robust and able to handle testing while being easy to fabricate, enhancing both quality and output.

Examples & Analogies

Consider the process of building a new playground. If the playground is designed for fun (DFT) but is also built with materials that withstand wear and tear (DFM), then it will serve its purpose well and last longer. Similarly, when designing chips, ensuring that both testability and manufacturability are prioritized results in a product that offers high performance and reliability, just like a well-constructed playground.

Key Concepts

-

DFT Techniques: Including scan chains and BIST for making chips testable.

-

DFM Principles: Focus on designs that are easy to manufacture and yield high-quality outcomes.

-

Integration of DFT and DFM: Essential for reliable and efficient semiconductor design.

Examples & Applications

Utilizing scan chains allows designers to efficiently test the logic within a chip.

Applying DFM principles, such as DRC, can prevent costly manufacturing defects.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

DFT and DFM, no need to cram, for chips that stand, the testing and making must go hand in hand.

Stories

Imagine two engineers: one named DFT, always checking for functionality in tests; the other, DFM, optimizing every detail to make sure production is stress-free and smooth.

Memory Tools

Remember 'DMT' for DFT (Design for Testability) and DFM (Design for Manufacturing) Working Together.

Acronyms

Use 'CHIP' to remember

for Cost reduction (DFM)

for High yield (DFM)

for Improved testability (DFT)

for Performance assurance (Both).

Flash Cards

Glossary

- Design for Testability (DFT)

Techniques implemented during design to make testing easier and more cost-effective.

- Design for Manufacturability (DFM)

Principles focused on optimizing design for the manufacturing process.

- Scan Chain Insertion

A DFT technique that adds flip-flops to allow easier access to test internal signals.

- Boundary Scan (JTAG)

A standard for testing interconnects using a shift register chain method.

- BuiltIn SelfTest (BIST)

Test logic embedded in a chip enabling it to test itself.

Reference links

Supplementary resources to enhance your learning experience.