Ductile Detailing as per IS 13920: 2016

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

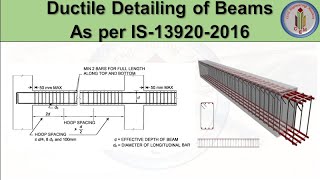

Beam Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will focus on beam detailing. Can anyone tell me why minimum and maximum reinforcement limits are important?

To ensure beams can handle the expected loads without failing?

Exactly! The minimum reinforcement is necessary to resist tension forces, and the maximum prevents issues like concrete cover spalling. What do you think anchorage length for bars entails?

I believe it’s how long the steel bars need to stay embedded in concrete to ensure they work together.

Correct! Proper anchorage is crucial for transferring loads effectively. Can anyone remind me what a hinge zone is?

I think it’s where plastic deformation is expected to occur.

Right! This is where we want sufficient confinement reinforcement to enhance energy dissipation. Let’s summarize: adequate reinforcement, anchorage, and hinge zones are key for ductile beam detailing.

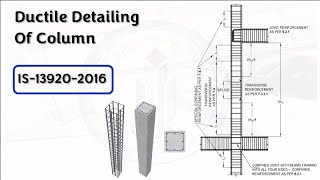

Column Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about column detailing. What does the term 'strong column–weak beam concept' refer to?

It means columns should be stronger than the beams to prevent collapse.

Yes! This allows the beams to yield first. What about the focus on transverse reinforcement in columns?

It’s to resist shear forces and prevent buckling, right?

Exactly! Correct spacing of transverse reinforcement is critical. Lastly, what can someone tell me about lap splices?

They help to join bars together at mid-height safely, right?

Absolutely! Adequate lap splicing is crucial for structural integrity. Let’s recap: columns need to be designed to remain strong under seismic loading while allowing ductility through controlled failure.

Beam-Column Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to beam-column joints. Why is confinement with closed ties or hoops necessary?

It helps to enhance joint strength and allows them to better transfer loads during seismic events.

Spot on! Additionally, what do we need to consider regarding shear strength requirements at joints?

They must be designed to withstand lateral forces without failing.

Exactly! Joints are vulnerable areas and need specialized detailing. Let’s summarize: proper confinement and shear strength considerations are crucial to joint performance under seismic loads.

Shear Wall Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss shear walls. What are boundary elements and why are they significant in shear wall design?

They help improve confinement and enhance the wall’s performance under lateral forces.

Correct! And what about vertical reinforcement in shear walls?

It needs to be distributed evenly to handle shear forces properly.

Right! Additionally, we have to think about detailing around openings or curtailments. What do you think is the primary concern there?

That they can weaken the wall if not done correctly, right?

Exactly! Effective detailing ensures that shear walls remain robust and perform optimally during seismic events. Let’s recap: proper boundary reinforcement and addressing openings are essential to shear wall design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ductile detailing is essential for earthquake-resistant design, providing guidelines on the reinforcement of beams, columns, joints, and shear walls. It focuses on ensuring adequate reinforcement, anchorage, and confinement, aiding structures in dissipating energy during seismic events.

Detailed

Ductile Detailing as per IS 13920: 2016

Ductile detailing is a fundamental aspect of designing reinforced concrete structures to withstand seismic forces, as per IS 13920: 2016. This section delineates vital factors for ensuring that structures possess sufficient ductility and energy dissipation capabilities, thus preventing catastrophic failures during earthquakes. The main subtopics include:

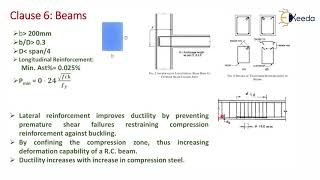

a) Beam Detailing

- Minimum and Maximum Reinforcement Limits: Ensuring beams have adequate tensile and compressive strength.

- Anchorage Length for Bars: Proper anchorage ensures load transfer between members.

- Hinge Zone Length and Confinement Reinforcement: These features help in enhancing the energy dissipation capacity during an earthquake.

b) Column Detailing

- Strong Column–Weak Beam Concept: This approach ensures that columns remain intact and absorb forces, allowing beams to yield and deform, preventing overall collapse.

- Transverse Reinforcement and Spacing: Adequate transverse reinforcement is required to handle shear forces and prevent buckling.

- Lap Splices at Mid-height: Properly designed lap splices contribute to the structural integrity in tensioned areas.

c) Beam–Column Joints

- Adequate Confinement with Closed Ties or Hoops: Essential for ensuring the joints remain robust under stress and provide effective load transfer.

- Shear Strength Requirements: Proper detailing ensures that joints can handle lateral forces without failure.

d) Shear Walls

- Boundary Elements for Confinement: Critical for stiffening shear walls and improving their energy absorption capabilities.

- Distributed Vertical Reinforcement: Helps maintain structural integrity and resistance to shear forces.

- Special Detailing for Openings and Curtailments: Must ensure that structural performance is not compromised by openings in shear walls.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Beam Detailing

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Minimum and maximum reinforcement limits.

• Anchorage length for bars.

• Hinge zone length and confinement reinforcement.

Detailed Explanation

Beam detailing focuses on reinforcing concrete beams to ensure they can handle seismic forces. The minimum and maximum reinforcement limits ensure that beams have enough strength without being over-reinforced, which can be counterproductive. Anchorage length for bars is the length that steel bars must be embedded in the concrete to ensure they grip effectively, providing the necessary tension strength. Hinge zones are specific areas in beams designed to rotate during an earthquake to absorb energy, and confinement reinforcement provides additional strength in these critical areas.

Examples & Analogies

Think of a beam as a swing on a playground. If the chains (reinforcement) are too short, it won’t hold well when kids swing hard (earthquake forces). If the chains are too long, they might not provide enough support at all. The right length ensures that the swing is safe and functions well, just like proper anchorage lengths ensure the beams can safely support the structure during seismic activity.

Column Detailing

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Strong column–weak beam concept.

• Transverse reinforcement and spacing.

• Lap splices at mid-height.

Detailed Explanation

Column detailing is important for keeping structural integrity during earthquakes. The 'strong column-weak beam' concept means columns are designed to be stronger than beams, allowing beams to flex and absorb shock without collapsing. Transverse reinforcement adds support in the form of ties around the primary rebar, which helps columns resist buckling. Lap splices are where two rebar sections overlap and connect; placing these at mid-height helps distribute stress more evenly across the column.

Examples & Analogies

Imagine a human body during a physical challenge like a tough exercise. Your legs (columns) need to be stronger than your arms (beams) to support your body weight; if your arms were stronger, they might give way when you try to push against something (the earthquake). Similarly, strong columns prevent the structure from collapsing while allowing beams to bend and absorb some forces.

Beam–Column Joints

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Adequate confinement with closed ties or hoops.

• Shear strength requirements.

Detailed Explanation

Beam-column joints are critical areas where beams meet columns. Adequate confinement with closed ties or hoops helps ensure that the joint can withstand the forces of an earthquake without failing. Shear strength requirements specify how much force the joint can handle before it starts to break apart. Proper detailing here prevents the failure of the structure during seismic events.

Examples & Analogies

This is like the knees in your body. Just as strong ligaments around the knees help them absorb shocks during running or jumping, closed ties around beam-column joints add strength and flexibility to withstand seismic forces.

Shear Walls

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Boundary elements for confinement.

• Distributed vertical reinforcement.

• Special detailing for openings and curtailments.

Detailed Explanation

Shear walls provide lateral strength to buildings during earthquakes. Boundary elements are thicker walls at the edges designed to prevent cracking and help contain forces. Distributed vertical reinforcement means having enough rebar vertically along the walls to handle compressive forces. Special detailing for openings (like windows or doors) is necessary to maintain strength and stability, ensuring that these areas remain secure even during seismic events.

Examples & Analogies

Think of shear walls like the columns of a bookcase that keep it balanced. Just as books (forces) pushing against the case must be countered to prevent it from toppling over, shear walls counteract lateral forces, ensuring the building remains standing. Having special supports where there are gaps (like doors) is similar to reinforcing weak points on a bookcase to maintain its integrity.

Key Concepts

-

Beam Detailing: Essential for ensuring beams can carry seismic loads with adequate ductility and strength.

-

Column Detailing: Columns must outlast beams in strength to maintain structural integrity during seismic activity.

-

Beam-Column Joints: Critical junctions that require adequate confinement and shear strength to resist earthquakes.

-

Shear Walls: Vertical elements designed to withstand lateral forces with special attention to detailing around openings.

Examples & Applications

In a concrete column, ensuring sufficient transverse reinforcement and appropriate lap splicing can drastically increase its performance during seismic events.

Strong column–weak beam detailing prevents overall structural collapse by allowing beams to deform before columns engage.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Reinforcement must be tight and strong, to keep structures safe all along.

Stories

Once upon a time, in a city prone to earthquakes, there were two buildings: one followed the strong column-weak beam rule and stood tall, while the other ignored it and crumbled during a quake.

Memory Tools

RAC (Reinforcement, Anchorage, Confinement) helps in seismic detailing.

Acronyms

BETS (Beams, Columns, Joints, Shear Walls) capture the essentials of ductile detailing.

Flash Cards

Glossary

- Ductility

The ability of a material to deform plastically before breaking, which is essential for structures to absorb seismic energy.

- Anchorage Length

The length of embedded rebar required to achieve weld or bond strength with concrete.

- Confinement Reinforcement

Reinforcement used to prevent buckling and enhance the strength of concrete columns or walls.

- Hinge Zone

Designated regions in structures expected to undergo deformation during seismic activity.

- Shear Wall

A vertical structural element that resists lateral forces through shear.

Reference links

Supplementary resources to enhance your learning experience.