Case Studies: Analyzing Thermal Management Strategies

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Thermal Management in ICs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we start with an introduction to thermal management in integrated circuits. Why do you think controlling heat is crucial in electronics?

Isn't it to prevent overheating and damage to the components?

Exactly! Managing heat helps maintain performance and reliability. Remember, as devices get smaller, they also get more power-dense, which makes heat management even more critical.

What happens if the heat isn't managed well?

Good question! Failure to manage heat can lead to thermal throttling, which reduces performance, or even complete failure of the electronics.

So, are there different strategies for managing heat?

Yes, and that leads us to our first case study on high-performance processors in consumer electronics.

Thermal Management Strategies in Consumer Electronics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In smartphones and gaming consoles, we see both passive and active cooling strategies. Can anyone name some cooling solutions?

I think thermal interface materials are used to help with heat dissipation?

Correct! TIMs improve heat transfer. What about active cooling solutions?

Heat sinks and fans could be examples?

That's right! Heat sinks made of materials like aluminum and copper help absorb and disperse heat effectively. Remember to note the challenges like size constraints, especially in smartphones, which we address with innovative materials like graphene.

What are thermal hotspots?

Hotspots are areas where concentrated heat builds up, often managed with systems like microchannel heat sinks. Let's summarize: effective thermal management in consumer devices prevents thermal throttling and enhances durability.

Thermal Management in Electric Vehicles

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's move to our case study on electric vehicles. What is a critical component that generates a lot of heat in EVs?

Inverters, which convert power, right?

Exactly! Given their high power density, what thermal management strategy do you think is employed?

Would liquid cooling be a good solution?

Very good! Liquid cooling manages the heat effectively. Challenges such as heat load require design innovations, like micro-channel cooling systems, to enhance heat removal efficiency.

What about thermal cycling?

Great point! Thermal cycling can cause material fatigue, which is why advanced ceramic materials help withstand these fluctuations.

Cooling Strategies in Data Centers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In data centers, what cooling systems are typically used to manage the heat generated by processors?

I think forced air cooling is common there.

That's correct! Additionally, immersion cooling is gaining traction for its efficiency. Can someone explain the benefits of these systems?

They can handle high power density without taking too much space, right?

Exactly! Utilizing space efficiently is key in these centers. To summarize, effective cooling strategies allow continuous operation despite the increasing load.

Thermal Management in Semiconductor Manufacturing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss semiconductor manufacturing. What are critical aspects of temperature management in this field?

Precision is really important so it should be kept constant.

Exactly! This requires active cooling solutions like chilled water loops and heat shields. Can anyone identify challenges faced?

Extreme temperature variations could lead to defects?

Correct! Energy efficiency in these systems is crucial too, as operational costs can be very high. Let’s recap how precision cooling enhances production quality.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details case studies from consumer electronics, electric vehicles, data centers, and semiconductor manufacturing, highlighting different thermal management strategies employed to ensure performance and reliability. Key solutions, challenges faced, and outcomes are analyzed for each case study.

Detailed

Case Studies: Analyzing Thermal Management Strategies

This section covers various case studies that illustrate the importance and complexity of thermal management in semiconductor devices across multiple applications. As the performance and density of integrated circuits (ICs) continue to increase, so does the challenge of heat dissipation.

1. Introduction to Thermal Management Case Studies

The introduction sets the stage for understanding the challenges of heat management in IC packaging, reinforcing its relevance in the performance and longevity of electronic devices.

2. Case Study 1: High-Performance Processors in Consumer Electronics

- Application: Focuses on devices like smartphones and gaming consoles.

- Thermal Management Strategy: Discusses passive and active cooling strategies, including thermal interface materials, heat sinks, and fan-based cooling.

- Challenges and Solutions: Addresses space constraints and thermal hotspots, leading to innovative solutions like thin heat sinks and microchannel designs.

3. Case Study 2: Power Electronics in Electric Vehicles (EVs)

- Application: Focuses on inverters and modules in EVs which require efficient heat management due to high current loads.

- Thermal Management Strategy: Primarily utilizes liquid cooling with heat sinks for supplementary cooling.

- Challenges and Solutions: Discusses the need to manage heat load and thermal cycling with micro-channel cooling systems and advanced materials.

4. Case Study 3: Data Centers and High-Performance Computing (HPC)

- Application: Emphasizes servers that require robust cooling systems.

- Thermal Management Strategy: Outlines the use of air cooling and liquid cooling techniques, including immersion cooling.

- Challenges and Solutions: Explores power density and space efficiency issues as key drivers for adopting advanced cooling systems.

5. Case Study 4: Semiconductor Manufacturing Equipment

- Application: Focus on precision tools like lithography machines.

- Thermal Management Strategy: Active cooling systems with chilled water loops and heat shields are utilized to maintain exact operating conditions.

- Challenges and Solutions: Discusses energy efficiency and the need for stable thermal environments to avoid defects in manufacturing.

Conclusion

The chapter highlights that effective thermal management is crucial across different industries, as it ensures the reliability, performance, and longevity of semiconductors. The integration of advanced cooling techniques demonstrates the innovation required in addressing the growing demands of modern technologies.

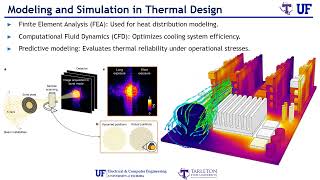

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Thermal Management Case Studies

Chapter 1 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In this chapter, we will explore real-world case studies to demonstrate how effective thermal management strategies are applied to address the challenges of heat dissipation in IC packaging. These case studies cover various industries and applications, highlighting the importance of selecting appropriate cooling solutions for different types of semiconductor devices.

Thermal management is essential for the performance, reliability, and lifetime of ICs, especially as devices become more compact and power-dense. By analyzing these case studies, we will see how different thermal management strategies are implemented in practice to ensure that devices operate within safe temperature limits.

Detailed Explanation

This introduction sets the stage for understanding the role and necessity of thermal management in integrated circuits (ICs). As electronic devices become smaller and more powerful, they generate more heat, which can affect their performance and lifespan. This section emphasizes the importance of using the right cooling methods tailored to specific devices and industries. The following case studies will illustrate how different strategies effectively manage heat dissipation in real-world applications, ensuring devices work efficiently without overheating.

Examples & Analogies

Consider a small car engine. If it doesn't have a proper cooling system, like a radiator, it can overheat and fail. Similarly, ICs need effective thermal management systems to prevent overheating as they function.

Case Study 1: High-Performance Processors in Consumer Electronics

Chapter 2 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Application: Smartphones, Laptops, and Gaming Consoles

Modern high-performance processors used in consumer electronics, such as smartphones, laptops, and gaming consoles, generate substantial heat during operation. The challenge is to design compact, energy-efficient thermal solutions that ensure the processor maintains peak performance without overheating.

Detailed Explanation

This chunk introduces the first case study, focusing on the thermal management challenges faced by high-performance processors in consumer electronics. It highlights devices like smartphones and laptops, which require compact yet effective cooling solutions to prevent overheating, ensuring that the devices operate smoothly and efficiently even under heavy usage conditions.

Examples & Analogies

Think of how a laptop feels warm when you're playing a high-performance video game. This warmth is due to heat generated by the processor, and just like how we need to ventilate a crowded room to make it comfortable, these devices need thermal management to stay cool.

Thermal Management Strategy for High-Performance Processors

Chapter 3 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

For these types of devices, a combination of passive cooling and active cooling solutions is employed:

● Thermal Interface Materials (TIMs): TIMs are used to improve heat transfer between the processor and the heat sink. The thermal grease or pads used ensure minimal thermal resistance at the interface, improving overall heat dissipation efficiency.

● Heat Sinks: Active cooling through heat sinks made of aluminum or copper is used. In some cases, heat pipes are incorporated into the heat sinks for better thermal conduction across the device.

● Fan-based Active Cooling: In devices like laptops and gaming consoles, small fans are used to force air over the heat sink to increase the rate of heat dissipation.

Detailed Explanation

This chunk outlines the specific thermal management strategies used for high-performance processors. It describes three key methods:

1. Thermal Interface Materials (TIMs) that enhance heat transfer from the processor to the heat sink, reducing thermal resistance.

2. Heat Sinks made of metals like aluminum or copper that actively draw heat away, sometimes with heat pipes for better efficiency.

3. Fan-based Active Cooling, where fans assist in cooling by circulating air around these components. Together, these strategies ensure that the processors stay cool and functional even under heavy loads.

Examples & Analogies

Imagine cooking a meal: you use a pot (the heat sink) that gets hot, and to cool it down faster, you might fan it with a piece of paper (the fans) or put it on a trivet (the TIMs) to let air circulate underneath. Similarly, these strategies help keep the processors from overheating.

Challenges and Solutions in Thermal Management

Chapter 4 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Size Constraints: In smartphones, the challenge lies in fitting these thermal management solutions into very compact spaces. To address this, thin heat sinks and graphene-based thermal materials have been incorporated to improve heat dissipation without taking up too much space.

● Thermal Hotspots: High-density processors in gaming consoles generate concentrated heat in specific areas. To mitigate this, microchannel heat sinks and integrated heat spreaders are used to distribute heat more evenly and avoid hotspots.

Detailed Explanation

This chunk highlights two main challenges in thermal management for high-performance processors.

1. Size Constraints: Compact devices like smartphones have limited space, making it hard to fit traditional cooling solutions. Engineers are innovating with thinner heat sinks and advanced materials like graphene, which can dissipate heat effectively without bulk.

2. Thermal Hotspots: Certain areas of devices can become excessively hot due to the concentrated processing power. To combat this, engineers use microchannel heat sinks — which have tiny channels for better heat distribution — and heat spreaders that help to evenly distribute heat across the processor.

Examples & Analogies

If you’ve ever had to cram a lot of clothes into a small suitcase, you know the challenge of limited space. Similarly, engineers must figure out how to fit effective cooling strategies into compact devices while still ensuring they function well without overheating.

Outcome for High-Performance Processors

Chapter 5 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This thermal management strategy ensures that the processors in smartphones, laptops, and gaming consoles can operate continuously under heavy loads without thermal throttling or failure, maintaining performance and reliability.

Detailed Explanation

This chunk summarizes the successful outcomes of the thermal management strategies applied to high-performance processors. By effectively managing heat, these strategies prevent overheating, allowing devices to function continuously at high performance. This means devices can handle demanding tasks without slowing down or failing, contributing to user satisfaction and product reliability.

Examples & Analogies

Think of this as a high-speed train running without stopping. As long as the train has adequate cooling, it can maintain its speed and performance without derailing. Just like that train, effective thermal management keeps the processors working efficiently without downtime.

Case Study 2: Power Electronics in Electric Vehicles (EVs)

Chapter 6 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Application: Electric Vehicle Inverters and Power Modules

In electric vehicles (EVs), power electronics such as inverters, which convert DC power from the battery to AC power for the electric motor, are essential components. These inverters handle high currents and generate significant heat, which must be efficiently managed to prevent performance degradation.

Detailed Explanation

This chunk introduces the second case study focused on the thermal management of power electronics in electric vehicles (EVs). It describes how inverters convert power from the battery and the intense heat generated during this process. Efficient thermal management is vital to keep these components functioning properly, as overheating can lead to inefficiency or failure.

Examples & Analogies

Imagine a chef who is processing multiple orders in a busy restaurant. If the stove gets too hot, the chef can’t cook efficiently and may burn the food. Just as the chef needs to manage the stove's heat, EVs need to manage the heat generated by inverters to maintain performance.

Thermal Management Strategy for EV Power Modules

Chapter 7 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

For EV power modules, liquid cooling is the primary method of thermal management due to the high power density and the need for precise temperature control.

● Liquid Cooling Plates: Liquid cooling systems use cold plates that are in direct contact with the power module. The coolant, typically water-based, is circulated through these plates, absorbing heat from the power module and transferring it to a radiator or heat exchanger.

● Heat Sinks with Thermal Conductive Pads: For supplementary cooling, heat sinks are used in combination with thermal pads to provide additional heat dissipation.

Detailed Explanation

This chunk reveals the specific thermal management strategy utilized for EV power modules, which primarily relies on liquid cooling. Two key components are highlighted:

1. Liquid Cooling Plates: These plates come into direct contact with power modules and use a circulating coolant to efficiently transfer heat away from the components.

2. Heat Sinks: Used alongside thermal pads, these help provide additional cooling by dispersing heat more effectively. Together, these methods maintain optimal operating temperatures and enhance performance.

Examples & Analogies

Think of how a car's radiator works to cool the engine. It circulates coolant to absorb and dissipate heat. In a similar way, liquid cooling plates and heat sinks work together to ensure that the power electronics in EVs remain cool and functional.

Challenges and Solutions in EV Thermal Management

Chapter 8 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Heat Load: The high power dissipation in power electronics often leads to large heat loads that require efficient and reliable heat removal. To address this, micro-channel cooling systems are designed to increase the surface area for heat transfer, improving the efficiency of heat removal.

● Thermal Cycling: Power modules in EVs experience frequent temperature changes during operation. To prevent mechanical failure due to thermal expansion and contraction, advanced ceramic materials and thermal interface materials with high durability are used in the design.

Detailed Explanation

This chunk addresses two major challenges in thermal management for EV power modules:

1. Heat Load: The significant heat generated demands efficient removal solutions. Micro-channel cooling systems increase the surface area of contact for better heat transfer, which enhances efficiency and prevents overheating.

2. Thermal Cycling: The frequent temperature fluctuations can cause mechanical strain on components. To combat this, durable materials are integrated into the design, ensuring that the modules withstand the stresses of thermal expansion and contraction without failing.

Examples & Analogies

Consider a light bulb that flickers when it heats up and cools down rapidly; this flickering can lead to burnout. Similarly, EV power modules need to maintain stability amidst temperature changes, using advanced materials to ensure reliability.

Outcome for EV Power Modules

Chapter 9 of 9

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The use of liquid cooling ensures that power modules in electric vehicles remain within their optimal operating temperature range, ensuring both high efficiency and reliability throughout the lifespan of the vehicle. This thermal management solution is crucial for ensuring the performance and safety of EVs.

Detailed Explanation

This chunk summarizes the outcomes of effectively implementing liquid cooling systems for EV power modules. By maintaining temperatures within a safe range, these systems ensure that the components operate efficiently and reliably. This is critical for the overall safety and performance of electric vehicles, as it contributes to their longevity and user trust in the technology.

Examples & Analogies

Just like how a well-maintained car engine can last for years, using liquid cooling to manage the heat in EVs enhances performance and ensures the vehicle can last longer and work better under various driving conditions.

Key Concepts

-

Thermal Management: The strategy for controlling device temperature.

-

Active vs. Passive Cooling: Techniques for heat dissipation.

-

Heat Load: The amount of heat energy that needs to be removed.

-

Thermal Hotspots: Areas where heat concentrates, risking damage.

-

Liquid Cooling: A method that uses liquids for thermal management.

Examples & Applications

Smartphones using graphene thermal materials to manage heat within tight spaces.

Electric vehicle inverters designed with micro-channel cooling to enhance efficiency.

Data centers employing immersion cooling methods to efficiently manage power density.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Heat must go, so sinks and fans flow, to keep devices performing, that we know.

Stories

Imagine a device trying to work hard on a hot day. It gets so warm, it starts to slow down. But with a nice, cool heat sink and gentle breeze from a fan, it stays active and speedy, never losing power!

Memory Tools

T.H.E. S.C.R.E.W. = Thermal management, Heat load, Effective cooling, Solutions, Components, Reliability, Efficiency, Weight.

Acronyms

C.H.A.S.E. = Cooling, Heat sinks, Active management, Solutions, Efficiency.

Flash Cards

Glossary

- Thermal Management

The process of controlling the temperature of a device to prevent overheating and ensure proper operation.

- Thermal Interface Materials (TIMs)

Substances applied between a heat source and a heat sink to enhance heat transfer.

- Heat Sink

A device that dissipates heat away from electronic components to maintain optimal temperatures.

- Microchannel Cooling

A cooling technology that uses small channels to improve the heat transfer area and efficiency.

- Liquid Cooling

A method of thermal management using liquids to absorb and transport heat away from a source.

- Immersion Cooling

A cooling technique where components are submerged in a dielectric fluid to dissipate heat.

- Chilled Water Loops

Cooling systems that circulate cold water to maintain temperatures in manufacturing equipment.

Reference links

Supplementary resources to enhance your learning experience.

- Introduction to Thermal Management in Electronics

- Cooling Strategies in Data Centers

- Thermal Management for Electric Vehicles

- An Overview of Semiconductor Manufacturing Process

- Liquid Cooling System Design

- Thermal Interface Materials in Electronics

- Fundamentals of Microchannel Heat Transfer

- A Review of Immersion Cooling Technology

- Heat Sinks in Electronics