Challenges and Solutions - 5.3.2

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Thermal Management in Electric Vehicles

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing the challenges faced by power electronics in electric vehicles. What do you think happens when too much heat builds up in these components?

I think it would affect their performance, maybe even cause them to fail.

That's correct! This is why thermal management is vital. One primary aspect is managing the heat load. Can someone explain what heat load means?

It refers to the amount of heat generated by the power electronics during operation, right?

Exactly! And excessive heat can degrade performance. That’s where solutions like micro-channel cooling systems come in. They increase the surface area for heat transfer. Can anyone explain how that helps?

More surface area means there's more space for heat to dissipate, making it more efficient!

Excellent point! So effective heat removal can ultimately enhance performance.

Challenges of Thermal Cycling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about thermal cycling. Why is it a concern in electric vehicles?

It's because the temperature changes can cause parts to expand and contract, which might lead to damage.

Exactly! To combat this, we use advanced materials. Can anyone name a type of material used for this purpose?

Are ceramics used because they can handle high temperatures?

That's right! They help prevent mechanical failure due to thermal stress. So, what have we learned about managing heat in EVs?

We have to ensure efficient heat removal to avoid performance issues and use durable materials to withstand temperature changes.

Great summary! Managing thermal challenges is critical to ensuring the reliability of electric vehicles.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In the realm of electric vehicles, managing the heat generated by power electronics is crucial for performance. This section discusses the significant challenges such as heat load and thermal cycling, along with effective solutions like micro-channel cooling systems and advanced materials that ensure reliable operation.

Detailed

Challenges and Solutions

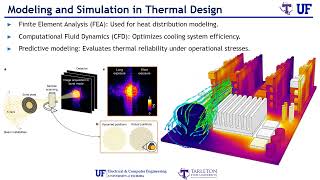

In this section, we delve into the thermal management challenges associated with power electronics used in electric vehicles (EVs), specifically focusing on inverters and power modules that convert DC power from batteries to AC power for electric motors. High current generation results in significant heat that must be efficiently managed to avoid performance degradation. The section details two major challenges:

- Heat Load: The high power dissipation in power electronics leads to substantial heat loads that necessitate effective heat removal strategies.

- Solution: Micro-channel cooling systems are designed to increase the surface area for better heat transfer, thereby enhancing heat removal efficiency.

- Thermal Cycling: Frequent temperature fluctuations during operation can cause mechanical failures due to thermal expansion and contraction.

- Solution: Advanced ceramic materials and robust thermal interface materials are utilized to withstand these thermal cycling challenges, ensuring the longevity and reliability of the components.

Overall, successful thermal management in EV power electronics is critical for enhancing both performance and reliability, reflecting the significance of careful design in maintaining optimal operating conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Heat Load Management

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Heat Load: The high power dissipation in power electronics often leads to large heat loads that require efficient and reliable heat removal. To address this, micro-channel cooling systems are designed to increase the surface area for heat transfer, improving the efficiency of heat removal.

Detailed Explanation

Heat load refers to the amount of heat generated by electronic components, particularly in high-performance applications. In electric vehicles (EVs), components like power modules can generate significant amounts of heat due to their high power usage. Managing this heat is critical to ensuring the components function effectively and do not suffer from overheating. One solution to this problem is the implementation of micro-channel cooling systems. These systems work by using very small channels within a cooling plate to allow a cooling fluid to flow and absorb heat. The increased surface area in these micro-channels enhances the heat transfer capabilities, making the cooling process much more efficient.

Examples & Analogies

Imagine a crowded concert venue where the heat from the audience rises significantly. If fans are placed throughout the crowd (like micro-channels), air can circulate better and cool off specific areas quicker than if there was just one large fan at the front. This analogy helps illustrate how distributed cooling mechanisms can manage heat more effectively than trying to centralize the cooling effort.

Thermal Cycling Management

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Thermal Cycling: Power modules in EVs experience frequent temperature changes during operation. To prevent mechanical failure due to thermal expansion and contraction, advanced ceramic materials and thermal interface materials with high durability are used in the design.

Detailed Explanation

Thermal cycling refers to the repeated heating and cooling of electronic components during their operation, which can cause stresses and strains due to expansion and contraction. In power modules within electric vehicles, these temperature changes can occur rapidly depending on how the vehicle is being operated (for example, during acceleration or deceleration). To alleviate the risks associated with these thermal cycles, engineers use advanced materials like ceramics which can withstand these stresses. Thermal interface materials designed for high durability are also employed to ensure that they maintain effective thermal conductivity even as the temperature fluctuates. This approach helps prevent the mechanical breakdown of components over time.

Examples & Analogies

Think of a metal lid on a glass jar. If you heat the lid and then cool it quickly, the metal might warp or crack because it expands and contracts at a different rate than the glass. Similarly, in power modules, if components aren't designed to handle thermal cycling—which happens frequently when an EV operates—they might wear out or break down prematurely. Using the right materials helps to prevent such failures.

Key Concepts

-

Heat Load: Refers to the heat produced that must be managed.

-

Micro-channel Cooling: A method to enhance cooling efficiencies.

-

Thermal Cycling: Fluctuation of temperatures causing material stress.

-

Durability of Materials: Importance of using materials that withstand thermal changes.

Examples & Applications

Micro-channel cooling systems are common in power modules where high heat loads are present.

Using ceramics in EV production helps in maintaining performance during fluctuations in temperature.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cool it down and let it flow, heat's the enemy we all know!

Stories

Imagine a small EV struggling to climb a hill. It overheats until it gets a new cooling system that keeps it cool, allowing it to power through challenges.

Memory Tools

Remember HM for Heat Management: H (Heat Load) and M (Micro-channel cooling)!

Acronyms

HITS

Heat

Inverters

Thermal management

Solutions.

Flash Cards

Glossary

- Heat Load

The total amount of heat energy produced by power electronics during operation that needs to be dissipated to maintain performance.

- Microchannel Cooling Systems

Advanced cooling solutions designed with small channels to increase surface area for efficient heat transfer.

- Thermal Cycling

The repeated heating and cooling of materials that can lead to mechanical stress and failure.

- Advanced Ceramic Materials

Durable materials used in thermal management to withstand high temperatures and thermal expansion.

Reference links

Supplementary resources to enhance your learning experience.