Thermal Management Strategy - 5.5.1

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Thermal Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re exploring the significance of thermal management in semiconductor manufacturing. Why do you think it's essential for equipment like lithography machines?

Because these machines need to operate under strict temperature control to avoid defects in the wafers!

Exactly! Remember, precision is key. If temperatures fluctuate too much, we risk producing faulty products. Let's explore how active cooling plays a role.

What is active cooling, and how does it work?

Active cooling systems use chilled water loops that circulate around the equipment to remove heat. Think of it like a cooling system in your car, maintaining an optimal temperature. Can anyone think of an example?

I believe it’s similar to how radiators work to keep a car engine from overheating?

Great analogy! Both involve circulating a fluid to manage heat. Let's summarize: effective thermal management is vital for performance, and active cooling assists in maintaining those necessary temperature levels.

Heat Shields and Reflectors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's shift gears and discuss heat shields. What role do you think they play in lithography systems?

They probably protect sensitive areas from overheating, right?

Exactly! Heat shields reflect excess heat away from critical components. This is crucial in maintaining a stable environment for producing semiconductor wafers without defects. Can anyone elaborate on why stable temperatures are essential?

If the temperature is inconsistent, it could lead to defective wafers and a waste of materials!

Right! Maintaining temperature consistency ensures product quality. Let’s summarize: heat shields enhance operational stability, which is fundamental for semiconductor fabrication.

Challenges in Thermal Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What challenges do you think we encounter in thermal management within semiconductor manufacturing?

Extreme temperature variations could be a big issue?

Absolutely! Another challenge is ensuring energy efficiency. We have to maintain performance while managing costs. How does a closed-loop cooling system help with this?

It probably recycles the coolant, which reduces energy consumption?

Exactly right! Closed-loop systems minimize waste and are more effective. Recap time: key challenges include temperature consistency and energy efficiency, and effective solutions involve active cooling and heat management techniques.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the thermal management strategies that ensure precise temperature control in semiconductor manufacturing equipment. It discusses challenges such as extreme temperature variations and energy efficiency, along with solutions like active cooling systems and heat shields.

Detailed

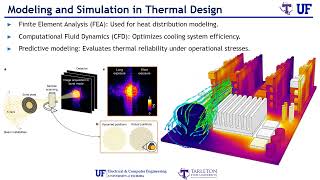

Thermal Management Strategy

In semiconductor manufacturing, effective thermal management is essential to ensure the precision and reliability of critical equipment such as lithography machines and etching tools. These devices require meticulous temperature control to produce high-quality semiconductor wafers without defects.

Active Cooling

Active cooling systems utilize chilled water loops to remove heat from crucial areas of the equipment. They incorporate cooling coils and heat exchangers to efficiently manage warm spots, safeguarding sensitive components from extreme temperatures.

Heat Shields and Reflectors

Heat shields are strategically employed in lithography systems to deflect excessive heat away from sensitive areas. These shields play a pivotal role in maintaining a stable temperature, which is vital for preventing defects during the manufacturing process.

Challenges and Solutions

- Extreme Temperature Variations: Precision manufacturing demands strict adherence to temperature controls. Active cooling minimizes fluctuations that can lead to defects in semiconductor wafers.

- Energy Efficiency: Given the significant energy costs of operating large-scale equipment, closed-loop cooling systems with heat exchangers enhance energy efficiency while ensuring consistent temperatures.

In summary, robust thermal management strategies are not only advantageous but essential for the production of high-quality semiconductor devices, affecting performance, yield, and operational costs.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Active Cooling Systems

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Active Cooling: Semiconductor manufacturing equipment employs chilled water loops to remove heat from critical areas. These systems use cooling coils and heat exchangers integrated into the machines.

Detailed Explanation

Active cooling refers to cooling systems that utilize mechanical components to actively move heat away from a device. In semiconductor manufacturing, chilled water loops are used to absorb excess heat from areas that are critical for maintaining performance. This is achieved through the use of cooling coils and heat exchangers that allow heat to flow away from components, ensuring they operate effectively.

Examples & Analogies

Think of a refrigerator. Just as it uses a cooling system to keep food and drinks cold by removing heat from inside, active cooling in semiconductor manufacturing works similarly - it removes excess heat from critical areas to keep the equipment at the right temperature.

Heat Shields and Reflectors

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Heat Shields and Reflectors: Heat shields are used in lithography systems to protect sensitive components from excessive heat. These shields reflect heat away from the critical parts, ensuring the temperature remains constant.

Detailed Explanation

Heat shields and reflectors are crucial in applications like lithography where precision is vital. These shields serve to deflect heat away from sensitive components, preventing overheating that could lead to defects in semiconductor production. By reflecting heat rather than allowing it to penetrate crucial areas, these shields help maintain a stable operating temperature.

Examples & Analogies

Imagine a car shielded from the sun by an umbrella. Just as the umbrella keeps the car cool by blocking sunlight, heat shields act to block excess heat from reaching important parts of the semiconductor manufacturing equipment, ensuring consistent performance.

Key Concepts

-

Thermal Management: Strategies to control heat in equipment, ensuring performance and reliability.

-

Active Cooling: A method of heat removal using chilled water loops.

-

Heat Shields: Components that reflect heat to protect sensitive areas.

-

Energy Efficiency: The ability to utilize less energy while achieving desired cooling effects.

Examples & Applications

Use of chilled water loops in semiconductor manufacturing equipment to ensure optimal temperature.

Heat shields protecting critical components in lithography machines.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To shield from heat and keep things neat, active cooling's what can't be beat!

Stories

Imagine a baker working in a hot kitchen. To keep their pastries perfect, they install cooling systems, just like active cooling in semiconductor manufacturing, ensuring everything remains on point!

Memory Tools

A for Active cooling, H for Heat shields, C for Closed-loop systems — remember the essentials!

Acronyms

ACH

Active cooling

Heat shields

Closed-loop systems

the trio of thermal management!

Flash Cards

Glossary

- Active Cooling

A thermal management technique using systems such as chilled water loops to remove heat from equipment.

- Heat Shields

Devices that reflect excessive heat away from sensitive components to maintain temperature stability.

- ClosedLoop Cooling Systems

Cooling systems designed to recycle coolant, enhancing energy efficiency.

Reference links

Supplementary resources to enhance your learning experience.