Outcome - 5.5.3

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Temperature Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore why temperature control is critical in semiconductor manufacturing. Why do you think maintaining a constant temperature is necessary?

I think it might be to ensure that the materials don't expand or contract too much?

Exactly! Fluctuations can create defects. We use active cooling systems to stabilize temperature. Can anyone suggest examples of such systems?

Chilled water loops could be one?

Great job! Chilled water loops help absorb heat efficiently. So, a stable temperature ensures high-quality semiconductor wafers.

Active Cooling Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s delve into how active cooling systems work. Can anyone explain what these systems typically involve?

They use things like water and heat exchangers to cool down the machines, right?

Precisely! By circulating coolant, they efficiently remove excess heat. How might this relate to energy efficiency in manufacturing?

If they use less energy to cool down, then the overall costs would go down?

That's correct! Better energy efficiency is crucial in keeping production costs low while maintaining quality.

Heat Shields and Reflectors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In addition to cooling, what protects sensitive components from excessive heat?

I remember heat shields!

Exactly! Heat shields reflect heat away from critical parts. Why do you think this is crucial?

If the sensitive parts get too hot, wouldn’t that lead to defects in the chips we’re making?

Absolutely! This shows how essential these protective measures are in maintaining high-quality semiconductor devices.

Energy Efficiency in Semiconductor Fabrication

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about how energy efficiency plays a role in thermal management. What are some ways the industry can become more energy-efficient?

Using closed-loop systems sounds like a good way to start.

Great insight! Closed-loop systems recycle coolant, which requires less energy. How does this directly affect production reliability?

It would keep the temperatures stable, making sure we get consistent results.

Correct! Stability in temperature leads to higher quality, which is crucial in the competitive semiconductor market.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

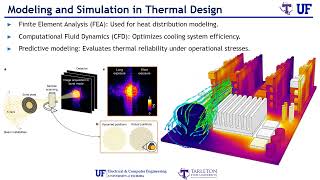

This section discusses the positive outcomes of efficient thermal management strategies implemented in semiconductor manufacturing equipment. These strategies ensure high precision and consistent performance, which are essential for producing high-quality semiconductor devices free from defects.

Detailed

Outcome

The section highlights the significance of effective thermal management strategies in semiconductor manufacturing equipment, particularly for lithography machines and etching tools. By employing advanced cooling methods such as active cooling and the use of heat shields, manufacturers can maintain precise temperature control. This control is crucial for the quality of semiconductor wafers, preventing defects and ensuring reliable production. As semiconductor technology becomes increasingly advanced, the need for efficient thermal management becomes more prominent, supporting the industry's push for higher quality and performance in semiconductor devices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Efficient Thermal Management

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Efficient thermal management in semiconductor manufacturing equipment ensures high precision, consistent performance, and defect-free wafer production, all of which are essential for the successful fabrication of high-quality semiconductor devices.

Detailed Explanation

This chunk emphasizes the critical role of effective thermal management strategies in semiconductor manufacturing. It highlights that maintaining the right temperature is vital for achieving precision in the production of semiconductor devices. If the temperature control is inadequate, it can lead to defects in the wafers produced, which can affect the quality and functionality of the final electronic products.

Examples & Analogies

Imagine baking a cake: if the oven temperature is too high or too low, the cake might not rise properly or could burn. Similarly, in semiconductor manufacturing, precise temperature control ensures that the 'cake' – in this case, the semiconductor wafers – comes out perfectly, free of defects.

Key Concepts

-

Efficient Thermal Management: Essential for the reliability and performance of semiconductor devices.

-

Active Cooling Systems: Employ various methods to maintain optimal operating temperatures.

-

Heat Shields: Important for protecting sensitive components from excessive heat.

-

Energy Efficiency: Improves production processes and reduces operational costs.

Examples & Applications

Using chilled water loops to cool lithography machines helps maintain precise temperature control.

Incorporating heat shields around sensitive components ensures they are not affected by excessive heat, leading to high-quality semiconductor production.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In semiconductors, keep it cool, with active methods as the rule!

Stories

Imagine a factory where machines are kept under control, with whispers of cool water navigating through pipes, and shields protecting delicate gears—this is the balance of heat and precision.

Memory Tools

Remember 'CHEW': Closed-loop, Heat shields, Efficient cooling, Warm parts kept safe!

Acronyms

ACE

Active Cooling and Energy efficiency is the path to high-quality semiconductor manufacturing.

Flash Cards

Glossary

- Thermal Management

Techniques and strategies used to control the temperature of devices and systems.

- Active Cooling

Cooling methods that require external energy or systems, such as chillers or fans, to remove heat.

- Heat Shields

Protective barriers that reflect excessive heat away from sensitive components.

- Chilled Water Loops

Systems that circulate cooled water to absorb and manage heat in manufacturing equipment.

Reference links

Supplementary resources to enhance your learning experience.