Challenges and Solutions - 5.5.2

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Thermal Management Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the thermal management challenges in semiconductor manufacturing. Can anyone share why precise temperature control is important in this field?

I think it's because even small temperature changes can affect the quality of semiconductors.

Exactly! Even minor fluctuations can lead to defects in semiconductor wafers. This is why they often employ active cooling methods. What do you think these methods could be?

Maybe they use cold air or refrigeration?

Good guess! They mainly use chilled water loops and cooling coils. This helps maintain steady temperatures. What do you think might happen if the temperature control fails?

Could it ruin the entire batch of products?

Absolutely! That's why maintaining thermal conditions is crucial. To remember this, think of the acronym THERMAL—Temperature Handling Ensures Reliability, Maintenance, and Accuracy in Lithography.

So, to summarize: precise temperature control prevents defects in semiconductor operations. Now, let's move on to speaking about energy efficiency.

Energy Efficiency Solutions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the challenges, let's talk about solutions specifically focused on energy efficiency.

Why is energy efficiency so important for these machines?

Great question! The operational costs can be significant, so reducing energy consumption helps lower the overall expenses. Do any of you know how they achieve energy efficiency?

Using better materials or systems maybe?

Correct! They utilize closed-loop cooling systems and heat exchangers. This minimizes energy waste and helps maintain consistent temperatures. Can anyone think of a real-world example where energy efficiency is maximally important?

Maybe in data centers or hospitals?

Exactly! Both environments rely heavily on energy efficiency to avoid high costs while ensuring reliability. To help remember this, think of the acronym EASY—Efficient Adaptable Systems Yield lower costs.

In summary, selecting energy-efficient cooling systems is paramount in semiconductor manufacturing to keep costs down while ensuring precision production.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

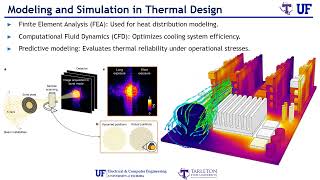

The section delves into specific challenges related to extreme temperature variations and energy efficiency in semiconductor manufacturing. It highlights the use of active cooling systems, heat shields, and advanced materials to maintain precise temperature control, thus ensuring the quality of semiconductor production.

Detailed

Challenges and Solutions

In semiconductor manufacturing, especially for lithography machines and etching tools, maintaining precise temperature control is critical. The section outlines two primary challenges:

- Extreme Temperature Variations: These machines operate in high-precision environments where deviations in temperature can lead to defects in semiconductor wafers. To counter these variations, active cooling solutions, such as chilled water loops and integrated cooling coils, are implemented to minimize thermal fluctuations.

- Energy Efficiency: Given the significant operational costs of large-scale manufacturing equipment, energy-efficient cooling systems are mandatory. The use of closed-loop cooling systems employing heat exchangers helps maintain consistent temperatures while reducing overall power consumption.

Through effective thermal management strategies, semiconductor manufacturers can ensure high precision, reliability, and defect-free production, which are essential in the fabrication of high-quality semiconductor devices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Extreme Temperature Variations

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Extreme Temperature Variations: Semiconductor manufacturing requires strict temperature control, and the equipment operates in high-precision environments. Active cooling solutions ensure that thermal variations are minimized, preventing defects in the semiconductor wafers.

Detailed Explanation

This chunk addresses the challenge of extreme temperature variations in semiconductor manufacturing. The precision of the equipment is critical, meaning that any fluctuation in temperature can lead to defects in the semiconductor wafers being produced. To counteract this issue, active cooling solutions are employed. These systems work continuously to maintain a stable temperature, which helps in preventing any potential defects during production. This ensures that the integrity and quality of each wafer is upheld, ultimately leading to reliable semiconductor products.

Examples & Analogies

Think of semiconductor manufacturing like a restaurant kitchen where several delicate dishes are being made at the same time. Just like a chef needs to maintain the right cooking temperature for each dish to avoid burning or undercooking, semiconductor equipment must maintain precise temperatures to avoid defects in their products. If the temperature in the kitchen varies too much, the chef may end up with poorly cooked meals, just like how variations in temperature can lead to faulty semiconductor wafers.

Energy Efficiency

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Energy Efficiency: Cooling systems in semiconductor fabrication must be energy-efficient, as the cost of running large-scale equipment is significant. The use of closed-loop cooling systems with heat exchangers helps reduce energy consumption while maintaining consistent temperatures.

Detailed Explanation

This chunk discusses the importance of energy efficiency in cooling systems used in semiconductor fabrication. The large-scale equipment often leads to high operating costs, prompting the need for efficient cooling solutions. Closed-loop cooling systems are introduced here; they recirculate coolant, minimizing waste and energy consumption while still effectively managing temperatures. Heat exchangers play a crucial role as they transfer heat from the coolant to the outside environment without losing the coolant's energy, thereby improving overall efficiency.

Examples & Analogies

Imagine running a home air conditioning unit in the summer. If your AC is not energy-efficient, you might get a huge electricity bill at the end of the month. By switching to an energy-efficient model, you keep your home cool while using less electricity and saving money. Similarly, semiconductor manufacturing requires energy-efficient cooling systems; when the systems are designed to save energy, they help keep costs down while ensuring that the equipment operates smoothly and effectively.

Key Concepts

-

Thermal Management: Techniques and strategies for managing heat in electronic devices.

-

Extreme Temperature Variations: Occurrences of significant changes in temperature that can affect device performance.

-

Energy Efficiency: Using methods to minimize energy consumption while maintaining device functionality.

Examples & Applications

Using chilled water loops in manufacturing equipment to maintain optimal temperatures.

Implementing heat shields in lithography machines to prevent overheating of sensitive materials.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Chilled water cools, heat won’t pile, making semiconductors last for a while.

Stories

Imagine a factory where machines work hard to create perfect chips. They need to stay cool, so they drink chilled water like athletes, ensuring the product is flawless.

Memory Tools

THERMAL: Temperature Handling Ensures Reliability, Maintenance, and Accuracy in Lithography.

Acronyms

EASY

Efficient Adaptable Systems Yield lower costs.

Flash Cards

Glossary

- Active Cooling

Methods of cooling that involve mechanical systems, such as chilled water loops, to remove heat from equipment.

- Heat Shield

A protective layer used to reflect excessive heat away from sensitive components.

- Energy Efficiency

The goal of reducing energy consumption while maintaining the same level of performance.

- ClosedLoop Cooling System

A system that recirculates a coolant to remove heat, ensuring energy efficiency.

Reference links

Supplementary resources to enhance your learning experience.