Case Study 4: Semiconductor Manufacturing Equipment

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Thermal Management Strategies in Semiconductor Manufacturing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into the thermal management strategies used in semiconductor manufacturing equipment, particularly lithography machines and etching tools. Can anyone tell me why thermal management is crucial here?

I think it's because they need to maintain precise temperatures to avoid defects in the wafers?

Exactly! Precise temperature control is vital in semiconductor fabrication. These defects can lead to malfunctions in the final product.

What kind of strategies are used to manage the heat?

Great question! One primary method is Active Cooling, which often involves chilled water loops. These loops help dissipate heat efficiently from the equipment. Can anyone guess how heat shields play a role here?

They prevent sensitive parts from getting too hot, right?

That's right! Heat shields reflect excessive heat away from critical components to maintain consistent temperatures.

Are there challenges in using these cooling techniques?

Absolutely! One significant challenge is managing extreme temperature variations. This requires effective active cooling to help stabilize temperatures. To summarize, we must use both active cooling and heat shields to ensure high precision during semiconductor manufacturing.

Energy Efficiency in Thermal Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's now look into energy efficiency in semiconductor thermal management. Why do you think it's so important?

I guess it helps reduce the costs of running the equipment?

Exactly! Large-scale semiconductor fabrication can be very energy-intensive. That's why closed-loop cooling systems with heat exchangers are implemented. They help keep energy consumption low while maintaining consistent cooling.

So, this means we can keep the equipment running without spending too much on energy?

Precisely! This balance ensures operational effectiveness and reduces costs significantly. Can anyone explain how active cooling can adapt to temperature changes?

It probably modulates the coolant flow based on the heat generated, right?

Yes, that's an excellent observation! Active cooling systems can be adjusted based on real-time temperature data, ensuring maximum efficiency.

What’s the outcome of implementing these thermal management strategies?

The outcome is high precision, consistent performance, and defect-free wafer production, crucial for high-quality semiconductor devices.

Challenges in Semiconductor Manufacturing Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the specific challenges semiconductor manufacturers face when managing heat. Can anyone identify a major challenge?

Extreme temperature variations can be an issue, especially if the machines don’t maintain temperature control.

Great insight! These variations can introduce defects in the wafers. What can be done to mitigate this issue?

Active cooling systems will need to be really efficient and sensitive to changes.

Correct! In addition, ensuring that cooling systems are energy-efficient is critical in modern fabrication processes. Does anyone know why it is particularly important for large-scale operations?

Because running lots of machines all day can be really expensive!

Exactly! The implementation of efficient cooling systems not only cuts costs but also ensures consistent production quality. Remember: balanced thermal management leads to defect-free devices.

Summary of Thermal Management Strategies

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s summarize our learning about thermal management in semiconductor manufacturing. What are the key methods we've discussed?

Active cooling and heat shields are key methods to manage thermal issues.

Correct! Now, why are these strategies significant specifically for semiconductor equipment?

They ensure high precision and consistency in wafer production, avoiding defects.

Exactly! In conclusion, using efficient thermal management strategies is essential to achieve high-quality semiconductor devices. Can anyone recap how energy efficiency plays into that?

By using closed-loop systems and heat exchangers, manufacturers can save energy costs while keeping the machines at optimal temperatures.

Great summary! This illustrates the vital interplay between effective thermal management and production quality in semiconductor fabrication.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In semiconductor manufacturing, effective thermal management is crucial for maintaining precision and reliability in fabricating semiconductor wafers. This section discusses the active cooling systems, heat shields, challenges of extreme temperature variations, and the importance of energy-efficient solutions in lithography machines and etching tools.

Detailed

Detailed Summary

In the realm of semiconductor manufacturing, maintaining precision and reliability during the fabrication of semiconductor wafers is of utmost importance. The tools utilized for these processes—such as lithography machines and etching tools—depend heavily on efficient thermal management strategies to ensure that temperatures are controlled to avoid defects in the wafers.

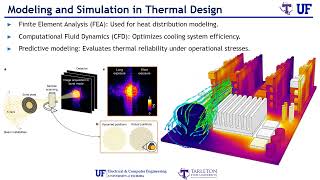

Thermal Management Strategy

The section outlines a few fundamental methods of thermal management:

- Active Cooling: The main strategy involves the use of chilled water loops that circulate coolant throughout the equipment to remove excess heat from critical regions.

- Heat Shields and Reflectors: These components are essential in lithography systems to protect sensitive elements from excessive temperatures, ensuring that operational temperatures remain stable.

Challenges and Solutions

Some challenges faced include:

- Extreme Temperature Variations: Precision environments require strict temperature control to minimize defects.

- Energy Efficiency: As costs are a concern for large-scale operations, closed-loop cooling systems with heat exchangers are emphasized to maintain efficient temperature management.

Outcome

The implementation of these thermal management systems results in high precision, consistent performance, and defect-free production of semiconductor devices, highlighting the critical role of effective thermal strategies in modern manufacturing.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Application Overview

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Application: Lithography Machines and Etching Tools

In semiconductor manufacturing, precision and reliability are paramount. Lithography machines and etching tools, which are used to fabricate semiconductor wafers, require precise temperature control to ensure the quality of the components.

Detailed Explanation

This chunk outlines the application of thermal management in semiconductor manufacturing, specifically mentioning lithography machines and etching tools. These tools are critical in the production of semiconductor wafers, which need to be manufactured with high precision. The control of temperature is very crucial because any deviation can negatively affect the quality of the wafers, which in turn impacts the overall performance of semiconductor devices.

Examples & Analogies

Think of it like baking a cake; if the oven temperature is too high or too low, the cake won’t rise properly or may burn. Similarly, in semiconductor manufacturing, keeping the right temperature is essential to 'bake' high-quality wafers.

Thermal Management Strategy

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Active Cooling: Semiconductor manufacturing equipment employs chilled water loops to remove heat from critical areas. These systems use cooling coils and heat exchangers integrated into the machines.

● Heat Shields and Reflectors: Heat shields are used in lithography systems to protect sensitive components from excessive heat. These shields reflect heat away from the critical parts, ensuring the temperature remains constant.

Detailed Explanation

This chunk describes the specific thermal management strategies employed in semiconductor manufacturing equipment. Active cooling systems, particularly chilled water loops, are utilized to dissipate heat effectively. These systems have cooling coils that circulate cold water to absorb heat. Additionally, heat shields and reflectors are used to protect sensitive components from heat influx, ensuring that the temperature remains stable and within the required range for the operation of the equipment.

Examples & Analogies

Imagine a high-tech refrigerator that not only keeps food cool but also uses shields to deflect any extra heat from the outside. This concept parallels how heat shields function in manufacturing equipment, keeping everything at just the right temperature.

Challenges and Solutions

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Extreme Temperature Variations: Semiconductor manufacturing requires strict temperature control, and the equipment operates in high-precision environments. Active cooling solutions ensure that thermal variations are minimized, preventing defects in the semiconductor wafers.

● Energy Efficiency: Cooling systems in semiconductor fabrication must be energy-efficient, as the cost of running large-scale equipment is significant. The use of closed-loop cooling systems with heat exchangers helps reduce energy consumption while maintaining consistent temperatures.

Detailed Explanation

In this chunk, the challenges faced during semiconductor manufacturing due to temperature variations are discussed. Extreme temperature control is needed to avoid defects in the wafers; thus, active cooling solutions play a vital role in minimizing these variations. Another significant challenge is ensuring energy efficiency since the costs tied to cooling large-scale manufacturing equipment can be high. Therefore, closed-loop cooling systems with heat exchangers are implemented to optimize energy use while effectively maintaining the necessary temperature.

Examples & Analogies

Consider a high-performance gaming system that needs to manage both performance and power consumption efficiently. Just like gamers often require fans and cooling systems to keep their systems from overheating without using too much power, semiconductor equipment must achieve a balance between sufficient cooling and energy efficiency.

Outcome of Effective Thermal Management

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Efficient thermal management in semiconductor manufacturing equipment ensures high precision, consistent performance, and defect-free wafer production, all of which are essential for the successful fabrication of high-quality semiconductor devices.

Detailed Explanation

This chunk summarizes the positive outcomes that arise from implementing efficient thermal management strategies in semiconductor manufacturing. These outcomes include achieving high precision in the manufacturing process, maintaining consistent performance of the equipment, and producing wafers that are free from defects. These factors are crucial for the successful fabrication of high-quality semiconductor devices, which are foundational to modern technology.

Examples & Analogies

Think of it as the quality control process in a factory. Just like factories must ensure that every product meets a certain standard to avoid returns or failures, the semiconductor industry relies on effective thermal management to ensure that every wafer meets the high standards necessary for technology performance.

Key Concepts

-

Active Cooling: A method to remove excess heat from equipment, usually involving chilled water.

-

Heat Shields: Protective components that reflect heat, critical for sensitive manufacturing processes.

-

Energy Efficiency: Key consideration for semiconductor manufacturing aimed at reducing operational costs.

Examples & Applications

Examples of active cooling include the use of chilled water loops in lithography machines, which help maintain the desired temperature.

Heat shields in lithography systems protect sensitive machinery parts from undue thermal exposure.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the heat of tech so grand, / Cool it down, take a stand! / Active cooling's the way to go, / Keep the chips in steady flow!

Stories

Imagine a factory where tiny chips are crafted. In this intricate dance of machines, cool waters flow around metal parts, while shields protect each vital piece from the fiery embrace of heat—ensuring each chip is perfect.

Memory Tools

Remember the phrase 'ACE': Active Cooling, Energy Efficiency, Shielding helps you keep semiconductor production free from defects.

Acronyms

COLD

Chilled water

Optimal temperature

Less energy waste

Defect-free production.

Flash Cards

Glossary

- Active Cooling

A method of managing heat by utilizing systems like chilled water loops to remove heat from equipment.

- Heat Shields

Components used in semiconductor systems to protect sensitive parts from excessive heat.

- ClosedLoop Cooling Systems

Efficient cooling systems designed to minimize energy consumption while maintaining consistent temperatures.

- Semiconductor Wafer

A thin slice of semiconductor material used in the fabrication of integrated circuits.

- Energy Efficiency

The goal of reducing energy consumption while maintaining efficient operational effectiveness.

Reference links

Supplementary resources to enhance your learning experience.