Common Materials Used as Joint Fillers

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Joint Fillers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into joint fillers. Can anyone tell me why joint fillers are used in concrete pavements?

I think they help with the expansion of concrete due to temperature changes!

Exactly! They accommodate the expansion and contraction of concrete. Now, can someone name a common material used as a joint filler?

What about sponge rubber?

Great answer! Sponge rubber is indeed a common filler because it is lightweight and highly compressible. Remember the acronym 'RACE' – Resilience, Accommodate, Compressibility, Easy installation. RACE to remember essential qualities of joint fillers.

What other materials do we have?

Wonderful question! We also have bituminous premoulded fillers, cork, cellulose fiberboard, and expanded polystyrene, each with unique properties and applications. Such diversity is crucial in choosing the right filler for each situation.

Can you explain more about the bituminous fillers?

Of course! Bituminous premoulded fillers are made from a combination of bitumen and fibers, providing excellent resilience in various conditions. They are particularly common in places like India.

To recap, joint fillers are essential for maintaining the integrity of concrete pavements, and materials like sponge rubber and bituminous fillers play key roles.

Properties of Joint Fillers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss what makes a good joint filler material. What properties do you think are important?

It should be durable, right?

Absolutely! Durability is crucial. Other properties include high compressibility, recovery after compression, and resistance to extrusion. Can anyone think of why these properties matter?

I guess if they can recover, they’d work better over time?

Exactly! The ability to recover is very important for joint fillers, ensuring they can handle repeated stress. Moreover, they should be non-absorbent to prevent moisture issues. Remember the properties using the mnemonic 'CRAM' – Compressibility, Recovery, Absorption resistance, and Mechanical strength.

What happens if they don’t have these properties?

Great question! If they lack these properties, the filler may fail, leading to deterioration of the pavement. So, we must select materials thoughtfully.

So, it's all about choosing the right material?

Exactly! Choosing the right filler ensures long-lasting performance. Remember CRAM for properties that matter!

Common Types of Joint Fillers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the common materials used as joint fillers! Who can name one?

Cork! It’s natural and compressible.

Excellent! Cork is fantastic for its natural compressibility. Now let's look at another—what do we know about expanded polystyrene?

It’s lightweight and resilient!

Correct! Its lightness makes it easy to handle. Remember the term 'ECRISP' – Easy, Compressible, Resilient, Ideal for installation, Sponge-like, Polystyrene. Use ECRISP to remember why EPS is widely used.

What about sponge rubber? How does it compare?

Great question! Sponge rubber is also highly compressible and is quite easy to install, another good choice for joint fillers. However, it may not have the same insulation properties as EPS.

So are these used together sometimes?

Yes, they can be used in combination depending on project requirements. The critical point is understanding each material's unique benefits.

Let’s summarize: Materials like cork, EPS, and sponge rubber are common fillers chosen for their specific attributes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses various materials employed as joint fillers in concrete pavements, highlighting their compressibility, durability, and appropriateness for use in different contexts. Common fillers include bituminous premoulded fillers, cork, sponge rubber, cellulose fiberboard, and expanded polystyrene (EPS).

Detailed

In concrete pavements, joint fillers play a crucial role in accommodating the thermal expansion and contraction of concrete slabs. This section elaborates on several types of materials utilized as joint fillers, elaborating on their properties, applications, and significance in maintaining pavement quality. The primary joint filler materials discussed include:

- Bituminous Premoulded Fillers: These are made from a blend of bitumen and fibers, widely used for their resilience and suitability for varying temperature conditions.

- Cork: A natural, compressible material that is noted for its durability and performance across different environments.

- Sponge Rubber or Foam Sheets: These fillers are lightweight and highly compressible, making them easy to install.

- Cellulose Fiberboard: Impregnated with bitumen, this type provides additional waterproofing properties.

- Expanded Polystyrene (EPS): Recognized for its lightweight and resilient characteristics, EPS is a popular choice for many applications.

Each material has unique advantages that contribute to the longevity and sustainability of concrete pavements, ensuring they cope effectively with thermal and environmental stresses.

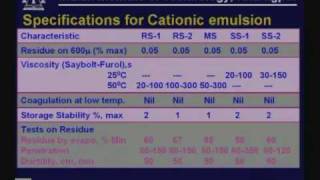

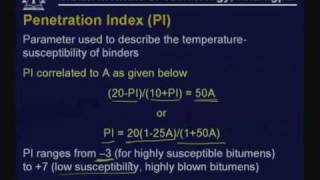

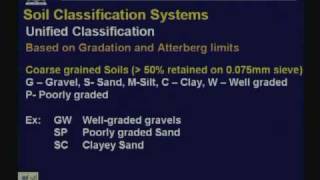

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Bituminous Premoulded Fillers

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Bituminous Premoulded Fillers: Made from bitumen and fibers, common in India.

Detailed Explanation

Bituminous premoulded fillers are materials made from a mixture of bitumen, which is a sticky oil-based substance, along with fibers. These fillers are specifically designed to be inserted into joints in concrete pavements. In India, they are a popular choice due to their ability to withstand various environmental conditions and the country's climatic challenges. The use of bituminous fillers helps in preventing water and debris from entering the joints, thus enhancing the longevity of the pavement.

Examples & Analogies

Think of bituminous premoulded fillers like a thick band-aid applied to a cut. Just as the band-aid protects the cut from dirt and helps it heal, these fillers protect the joints in concrete pavements from water and debris, allowing the concrete to expand and contract without damage.

Cork as a Joint Filler

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Cork: Natural, compressible, and durable.

Detailed Explanation

Cork is a natural material harvested from the bark of cork oak trees. It is highly compressible, which makes it ideal for joint fillers as it can easily absorb the movements of the concrete pavement without breaking down. Additionally, cork is known for its durability, meaning it can last a long time when used in pavement joints. The natural properties of cork also make it resistant to many environmental stresses, providing not just a functional but also an eco-friendly option for joint fillers.

Examples & Analogies

Imagine a sponge that soaks up water. Just like how a sponge can compress and expand while absorbing liquid, cork works similarly in pavement joints, compressing as concrete expands and then returning to its initial shape, maintaining the structure's integrity.

Sponge Rubber or Foam Sheets

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Sponge Rubber or Foam Sheets: Light, easy to install, and highly compressible.

Detailed Explanation

Sponge rubber or foam sheets are lightweight materials that can be easily handled and installed in joints of concrete pavements. Their high compressibility allows them to accommodate the movements of the concrete without losing shape or effectiveness. This flexibility makes them excellent for use in various climates and conditions, and they help to keep joint spaces sealed against moisture and debris. Their ease of installation also makes sponge rubber or foam sheets a popular choice among construction teams.

Examples & Analogies

Think of foam sheets like the padding in a pair of comfortable shoes. Just as the padding helps absorb shock and provides comfort while walking, sponge rubber or foam sheets absorb the movements of concrete, protecting the overall structure and extending its lifespan.

Cellulose Fiberboard

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Cellulose Fiberboard: Impregnated with bitumen for waterproofing.

Detailed Explanation

Cellulose fiberboard is a composite material made from recycled paper products, enhanced with bitumen for waterproofing properties. This combination creates a durable joint filler that resists moisture and helps prevent rot, making it an effective choice for pavement applications. The bitumen acts as a barrier against water ingress while the fiberboard provides structural support and compressibility.

Examples & Analogies

Imagine using a raincoat to protect yourself from getting wet in the rain. The cellulose fiberboard acts like that raincoat, shielding the concrete joints from water while also being strong enough to withstand the pressures placed upon it, ensuring that the pavement remains stable and long-lasting.

Expanded Polystyrene (EPS)

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Expanded Polystyrene (EPS): Lightweight and resilient.

Detailed Explanation

Expanded Polystyrene (EPS) is a lightweight material known for its resilience and excellent thermal insulation properties. Used as a joint filler, EPS can effectively absorb the movements of concrete slabs while providing cushioning. Its lightweight nature allows for easy installation, while it also helps to reduce the overall weight of the pavement system, making it an efficient choice in many construction projects.

Examples & Analogies

Consider how a beach ball floats in the water without sinking. EPS acts similarly in concrete joints, providing support without adding excessive weight to the pavement. Just as the beach ball adapts to water movements without losing its form, EPS can compress and expand alongside the concrete, ensuring lasting stability.

Key Concepts

-

Joint Fillers: Materials that accommodate expansion in concrete pavements.

-

Bituminous Fillers: Resilient materials commonly used in India for pavement joints.

-

Cork: A natural material known for its compressibility and durability.

-

Sponge Rubber: Lightweight fillers that are easy to work with.

-

Cellulose Fiberboard: Waterproof fillers that extend the life of pavements.

-

Expanded Polystyrene: Resilient and lightweight joint fillers.

Examples & Applications

Bituminous premoulded fillers are frequently utilized in regions with extreme temperature variations.

Cork is often used in areas where eco-friendliness is a priority due to its natural properties.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In pavement joints, fillers provide resilience, keeping cracks at bay, without hindrance.

Stories

Once upon a time, in the land of concrete, there lived different friends like Cork and EPS who always helped each other support the pavement in expanding times.

Memory Tools

Remember the 'ECRISP' for Expanded Polystyrene: Easy, Compressible, Resilient, Ideal for installation, Sponge-like, Polystyrene.

Acronyms

Use 'CRAM' to recall the vital properties

Compressibility

Recovery

Absorption resistance

Mechanical strength.

Flash Cards

Glossary

- Joint Fillers

Materials used to fill gaps in concrete joints, accommodating expansion and contraction.

- Bituminous Premoulded Fillers

Fillers made from bitumen and fibers, known for their resilience.

- Cork

A natural, compressible material used for its durability.

- Sponge Rubber

A lightweight, highly compressible material that is easy to install.

- Cellulose Fiberboard

A filler impregnated with bitumen for added waterproofing.

- Expanded Polystyrene (EPS)

A lightweight and resilient material often used as joint filler.

Reference links

Supplementary resources to enhance your learning experience.