Types of Joints in Concrete Pavements

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Expansion Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll be discussing expansion joints. Can anyone share what they think happens to concrete as temperatures rise?

I think it gets bigger or expands!

Exactly! Expansion joints are there to allow for this thermal expansion. Otherwise, the concrete would crack. We can remember this by the acronym 'E-A-R' for Easing A Rise in temperature. Does that help?

Yes! So, without these joints, we could have a lot of cracking.

That's correct. Expansion joints prevent that damage from occurring. Can anyone think of a situation where you might see these in real life?

Like big highways or bridges!

Great example! Let's recap—expansion joints allow for expansion. Remembering E-A-R can keep that in mind.

Contraction Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's move on to contraction joints. Who can tell me what they think happens when concrete shrinks?

It might crack in random places if we don’t control it!

Exactly right! Contraction joints help manage where cracking occurs. If we don't control it, we can end up with unsightly cracks. We use the phrase 'C-C' for Controlled Cracking to remember.

So, these joints are put in place to direct the cracks?

Precisely! By placing them strategically, we can ensure that the cracks happen where we want them to. Great job linking those concepts!

Construction Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss construction joints. How do we think these differ from expansion and contraction joints?

They probably happen when construction stops, right?

Exactly! Construction joints are placed where we stop pouring concrete and need to resume later. They help maintain continuity. Remember the acronym 'C-O-N-T' for Continuity Of New Tape for these joints.

So, it's a way to connect two different sections of concrete?

Exactly! So, every time we stop working, we need construction joints. Great recap!

Warping Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's explore warping joints. Can anyone explain why they are important?

Are they for dealing with different temperatures causing warping?

Correct! These joints allow for the warping caused by temperature differences. You can remember this as 'W-A-R-P' - Warping Accommodating Random Pressures. A handy mnemonic, right?

That helps a lot! So they help keep the pavement flat?

Yes! Great insight. To sum up, warping joints are fundamental in controlling how slabs behave under temperature changes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

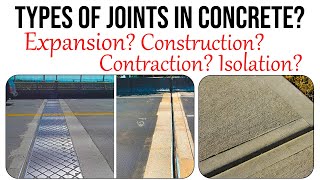

Concrete pavements incorporate different types of joints, including expansion, contraction, construction, and warping joints, each serving a specific function in accommodating movement due to temperature changes and shrinkage. Understanding these joints is essential for effective pavement design and longevity.

Detailed

Types of Joints in Concrete Pavements

Concrete pavements are subjected to movements from temperature variations, shrinkage, and other factors, making the design of joints vital for their durability. This section outlines the four primary types of joints found in concrete pavements:

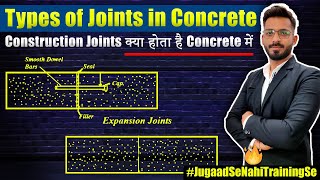

1. Expansion Joints

These joints are designed to allow for the thermal expansion of concrete. When temperatures increase, concrete expands, and these joints provide the necessary space to accommodate this movement without causing damage.

2. Contraction Joints

Contraction joints are strategically placed to control where cracking occurs due to the shrinkage of concrete as it cures and dries. By directing the cracks to specific locations, these joints help to maintain the integrity and aesthetic of the pavement.

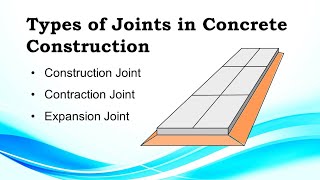

3. Construction Joints

These joints occur where the concrete placement is interrupted, allowing construction to be resumed later without compromising the structural integrity of the pavement. Proper consideration must be given to the location of these joints to ensure continuity and performance.

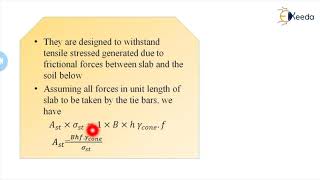

4. Warping Joints

Warping joints accommodate the warping and curling of concrete slabs caused by temperature gradients within the pavement. They help to minimize stress and potential cracking, preserving the surface integrity over time.

Understanding these joint types is critical in the design and maintenance of concrete pavements, contributing to their longevity and resilience against environmental factors.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Expansion Joints

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• 18.2.1 Expansion Joints: Allow for thermal expansion of concrete.

Detailed Explanation

Expansion joints are specifically designed to accommodate the natural expansion of concrete due to temperature changes. As temperatures rise, concrete slabs expand, and if there are no joints to allow this movement, the concrete can crack or buckle. These joints create gaps that enable the concrete to expand without causing damage.

Examples & Analogies

Think of expansion joints like the space between your finger joints. When your hand warms up, your fingers can spread out without pain or cracking due to the natural flexibility at the joints. Similarly, expansion joints in concrete pavements provide the necessary flexibility for the pavement.

Contraction Joints

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• 18.2.2 Contraction Joints: Control the location of cracking due to shrinkage.

Detailed Explanation

Contraction joints are introduced to intentionally control where cracks in concrete will occur as it shrinks. When concrete cures, it gets smaller, and without these joints, random cracks may develop throughout the pavement. The contraction joints create weak points in the concrete, directing the crack to these pre-determined locations and thus enhancing the aesthetic appearance and functionality of the pavement.

Examples & Analogies

Imagine a loaf of bread cooling down. As it cools, it shrinks and may crack if not handled correctly. If you were to cut slits in the bread while it's still warm, the cracks would happen along those cuts instead of randomly across the loaf, keeping it looking good. Similarly, contraction joints control where concrete will shrink and crack.

Construction Joints

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• 18.2.3 Construction Joints: Placed where construction is stopped and continued later.

Detailed Explanation

Construction joints are essential for projects that require multiple pouring sessions. They are placed where one section of concrete meets another, usually after construction work is paused. These joints ensure a smooth transition between the different concrete placements, maintaining structural integrity and providing clear boundaries for the slabs.

Examples & Analogies

Consider a puzzle. When one section is completed but the next cannot be attached immediately, the edges where the pieces meet create a boundary. Construction joints are like those edges, ensuring that even if you return later to finish the puzzle, the completed part fits nicely without any gaps.

Warping Joints

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• 18.2.4 Warping Joints: Account for warping and curling of slabs due to temperature gradients.

Detailed Explanation

Warping joints are designed to accommodate warping and curling that can occur in slabs when temperature differences exist across the slab. This type of joint allows the concrete to move and shift slightly without causing damage or cracking, which can happen when one part of the slab is more affected by heat than another, leading to uneven stresses.

Examples & Analogies

Think of a large piece of paper left in the sun. If only one side heats up while the rest stays cool, the paper starts to curl. Warping joints in concrete pavements function similarly, ensuring that as temperatures fluctuate, the concrete can adapt without becoming damaged, much like allowing that paper to stay flat.

Key Concepts

-

Expansion Joints: Allow thermal expansion to prevent cracking.

-

Contraction Joints: Control cracking due to shrinkage.

-

Construction Joints: Enable continuity when construction pauses.

-

Warping Joints: Manage warping caused by temperature gradients.

Examples & Applications

Expansion joints are often found in highways and large slab constructions to allow for temperature fluctuations.

Contraction joints are used in sidewalks and driveways to hide cracks instead of allowing them to be random.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If it expands, give it room; don't let cracking bring you gloom!

Stories

Once upon a time, in a land of concrete, there were segments that loved to expand and shrink. They made friends with joints that allowed them to move without fear of cracking up!

Memory Tools

Remember 'E-C-C-W' for the joints: Expansion, Contraction, Construction, Warping.

Acronyms

E-A-R for Expansion Allows Room.

Flash Cards

Glossary

- Expansion Joints

Joints that allow for the thermal expansion of concrete.

- Contraction Joints

Joints designed to control the location of cracking due to shrinkage.

- Construction Joints

Joints placed where construction has stopped and later resumed.

- Warping Joints

Joints that account for warping and curling of slabs due to temperature gradients.

Reference links

Supplementary resources to enhance your learning experience.