Introduction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Joint Fillers and Sealers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss the importance of joint fillers and sealers in concrete pavements. Can anyone tell me why we need to have joints in concrete?

Is it to allow the concrete to expand and contract?

Exactly! The concrete expands and contracts due to temperature changes. If we don't have joints, it will crack. Now, can anyone think about what might happen if water gets into those cracks?

The pavement could deteriorate faster because the water could freeze and expand.

That's correct! To prevent this, we use joint fillers to accommodate the expansion and sealers to protect the joints. Remember the acronym FAS—Filler And Sealer—for the two main functions!

So, the fillers are for expansion, and sealers prevent water from leaking in?

Precisely! Fillers provide spacing for expansion, and sealers ensure impermeability. Let's summarize: fillers for space—F, sealers for protection—A, and together they keep the pavement safe—S.

Effects of Inadequate Joint Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand why fillers and sealers are critical, what do you think could happen if they are not properly designed or maintained?

Maybe the joints could allow water in and cause bigger cracks?

Absolutely! Poor joint design can lead to issues like spalling and cracking. Can someone explain what spalling means?

Isn’t that when the surface of the concrete chips away?

Exactly! Left unchecked, spalling can compromise the structural integrity of the pavement. Let's remember—SAFE: Strong design, Adequate maintenance, and Filler and sealer application are essential!

Long-term Benefits of Proper Sealing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the long-term benefits of proper sealing. How do you think that impacts concrete pavement maintenance?

It must reduce the amount of repairs needed over time, right?

Exactly! Good sealants can extend the life of the pavement significantly. Who can think of an example where sealants could save money in the long run?

If we prevent water damage, then we won’t need to repair cracks as often!

Yes! And how about operational effectiveness—wouldn't it help with that as well?

Definitely, fewer repairs mean roads are closed less often, so traffic flows better!

Perfect! Remember, proper sealing leads to savings and smoother operations. Let’s recap: effectively sealed joints equal long-term benefits.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Concrete pavements are prone to cracking due to environmental factors and require effective joint fillers and sealers to manage these issues. Properly designed joint systems help protect pavements from deterioration and extend their service life.

Detailed

Introduction to Joint Fillers and Sealers in Concrete Pavements

Concrete pavements, while known for their strength and ability to support substantial loads, face challenges such as cracking caused by temperature changes, shrinkage, and expansion. Joints are strategically placed within concrete pavements to manage thermal movements and maintain their structural soundness. To prevent issues like water ingress and accumulation of debris—both of which can exacerbate pavement deterioration—it's vital to ensure these joints are properly filled and sealed.

Key Points Covered:

- The Purpose of Joints: Joints are essential for accommodating the natural movement of concrete, which expands and contracts under varying temperatures.

- Role of Joint Fillers and Sealers: Joint fillers accommodate expansion, while sealers provide a barrier against outside elements. They significantly enhance the lifespan and durability of the pavement.

- Significance of Material Selection and Maintenance: The choice of materials for fillers and sealers, along with regular maintenance practices, determines how effectively joints perform over time.

In summary, understanding the foundational aspects of joint fillers and sealers is crucial for effective pavement management and construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Concrete Pavements and Their Challenges

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Concrete pavements, despite their rigidity and high load-bearing capacity, are susceptible to cracking and damage due to temperature variations, shrinkage, and expansion.

Detailed Explanation

Concrete pavements are known for being strong and durable. However, they can develop cracks and other forms of damage when exposed to changes in temperature, which cause the concrete to expand and contract. Additionally, as the concrete dries, it can shrink. Both of these factors make it essential to consider protective measures to ensure the longevity of concrete pavements.

Examples & Analogies

Think of concrete pavements like a strong book. Just as a book can have its spine cracked or pages damaged if not carefully handled, concrete can crack or get damaged if not properly maintained, especially in varying temperature conditions.

The Importance of Joints

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To control these movements and maintain structural integrity, joints are provided in concrete pavements.

Detailed Explanation

Concrete pavements are designed with joints that allow for controlled movement. These joints are essential because they provide specific areas where the concrete can expand or shrink without leading to uncontrolled cracking. This strategic placement of joints is crucial for maintaining the structural integrity of pavements over time.

Examples & Analogies

Imagine a rubber band; it can stretch and contract without breaking because it is designed that way. Joints in concrete pavements function similarly, allowing the concrete to move without cracking.

Protection Against Deterioration

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These joints must be adequately protected to prevent the ingress of water, debris, and incompressible materials that can lead to pavement deterioration.

Detailed Explanation

Once joints are created in concrete pavements, it is vital to protect them from outside elements. Water and debris can seep into these joints, causing harm to the underlying structures and leading to deterioration. Therefore, protective measures are necessary to ensure that joints remain clear of unwanted materials and maintain their function.

Examples & Analogies

Think of the joints as the gateway to a garden. If the gate is left open, weeds and debris can invade and damage the plants. Similarly, if concrete joints are not protected, harmful materials can enter and cause deterioration.

Role of Joint Fillers and Sealers

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

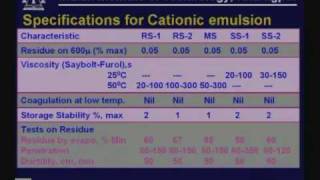

Joint fillers and sealers serve as essential components in the performance and durability of concrete pavements.

Detailed Explanation

Joint fillers and sealers play a crucial role in maintaining the effectiveness and lifespan of concrete pavements. Fillers are used to create space for concrete to expand, while sealers act as barriers that prevent moisture and debris from entering the joints. The right combination of both components is vital for the pavement's long-term performance and durability.

Examples & Analogies

Consider joint fillers and sealers as the insulation and waterproofing for your home. Just like insulation keeps your house energy-efficient, and waterproofing prevents water leaks, fillers and sealers protect concrete pavements from damage.

Importance of Proper Design and Maintenance

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper design, material selection, and maintenance of joint fillers and sealers are crucial for long-lasting pavement performance.

Detailed Explanation

To ensure that concrete pavements remain effective over time, attention must be paid to the design and selection of materials used for joint fillers and sealers. Regular maintenance is also essential to identify any issues early on and address them before they escalate into significant problems. This proactive approach enhances the lifespan and quality of the pavement.

Examples & Analogies

Just as a car requires regular servicing to run smoothly and efficiently, concrete pavements need thoughtful design, the right materials, and ongoing maintenance to perform well over time.

Key Concepts

-

Joint Fillers: Materials that provide space for the concrete's thermal expansion.

-

Joint Sealers: Protects against environmental damage by preventing water ingress.

-

Durability: Essential for ensuring pavement longevity and performance.

Examples & Applications

Example 1: Using bituminous premoulded fillers for expansion joints in asphalt pavements to accommodate temperature-induced movements.

Example 2: Applying polysulfide sealants to concrete joints in a highway to prevent water damage from rain.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fillers keep concrete sound, sealers catch water all around.

Stories

Imagine a concrete road without joints; it cracks under pressure. Fillers are like pillows, making space for stretches; sealers are the raincoats, keeping the road safe from wetness.

Memory Tools

Remember FAS—Filler absorbs, And Seals protect!

Acronyms

FAS

Filler for expansion

for access

for sealing!

Flash Cards

Glossary

- Joint Fillers

Materials inserted into concrete joints to accommodate expansion and contraction.

- Joint Sealers

Substances applied to joints to prevent water and debris ingress.

- Spalling

The chipping or flaking of the surface concrete resulting from moisture infiltration or freeze-thaw cycles.

- Durability

The ability of materials to withstand wear, pressure, or damage.

Reference links

Supplementary resources to enhance your learning experience.