Contraction Joints

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Contraction Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're focusing on contraction joints. Can anyone tell me why they are important in concrete pavements?

I think they help prevent cracking, right?

Exactly! Contraction joints are designed to control where cracking happens due to shrinkage. This helps maintain the pavement's structural integrity.

So, without them, cracks could appear anywhere?

Correct! By controlling the crack locations, we can minimize damage and extend the life of the pavement.

Are there any specific factors that decide where to place these joints?

Good question! Factors such as slab size, expected temperature variations, and traffic loads all influence placement.

To summarize, contraction joints are crucial as they manage cracking, helping preserve the pavement's functionality.

Design Considerations for Contraction Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive into how to design effective contraction joints. What do you all think is necessary for a successful design?

I assume the size and spacing of the joints is important?

Absolutely right! The size and spacing should be determined based on the expected shrinkage and environmental conditions.

What about the depth of the joint?

Great point! The depth is also critical. A properly designed depth limits the width of cracks and ensures durability.

In summary, effective contraction joint design involves careful consideration of joint size, spacing, and depth to control cracking.

Maintenance of Contraction Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's wrap up our discussion by talking about the maintenance of contraction joints. Why do you think maintenance is necessary?

To keep them in good shape and stop water from getting in?

Yes! Regular maintenance ensures that joints remain effective in preventing water ingress and protecting against deterioration.

How often should they be checked?

It's recommended to inspect them regularly, especially after harsh weather changes.

In summary, maintenance is crucial for the durability and performance of contraction joints. Regular inspection can help identify issues before they become severe.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses contraction joints, which are designed to control cracking in concrete pavements caused by shrinkage. It emphasizes their importance in maintaining structural integrity and outlines the principles behind their implementation.

Detailed

Contraction joints are essential components in concrete pavements that help regulate the cracking caused by shrinkage. When concrete cures, it tends to shrink, leading to potential cracking that could compromise the pavement's integrity. By strategically placing contraction joints, engineers aim to control where these cracks occur, minimizing their impact on the structure. Proper design, execution, and maintenance of these joints are vital to ensure the longevity and durability of the pavement. This section also highlights the criteria for effective contraction joint placement and its significance in the overall performance of concrete pavements.

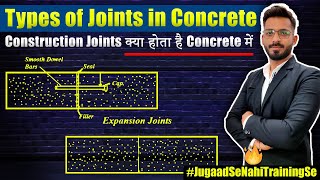

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of Contraction Joints

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Contraction joints control the location of cracking due to shrinkage.

Detailed Explanation

Contraction joints are specifically designed to avoid random cracking in concrete as it shrinks. Concrete can shrink due to different factors such as drying out or temperature changes. These joints provide a predetermined location where the concrete is allowed to crack, thereby ensuring that the cracks occur in a controlled manner rather than occurring unpredictably across the surface.

Examples & Analogies

Think of contraction joints like the lines on a chocolate bar. When you break a chocolate bar, it usually cracks along these lines, which helps it break neatly rather than shatter unpredictably. Similarly, contraction joints help direct the cracks in concrete in a neat pattern.

Functionality of Contraction Joints

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These joints are crucial for maintaining the structural integrity of concrete pavements.

Detailed Explanation

By directing the shrinkage cracks to specific areas, contraction joints help maintain the overall strength of the pavement. Without these joints, cracks might propagate randomly which could lead to larger structural failures. The placement of these joints helps in distributing stress more evenly across the concrete surface and minimizes potential damage.

Examples & Analogies

Imagine a bridge made of flexible materials like rubber bands. If the rubber bands were not strategically aligned, they might snap at random places under stress. Contraction joints are like those strategic alignments, ensuring that the stress is managed effectively.

Placement of Contraction Joints

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper placement of contraction joints is vital to their effectiveness.

Detailed Explanation

For contraction joints to function effectively, they must be placed at appropriate intervals and locations in the concrete slab. Generally, these joints are spaced every 10 to 15 feet, but this can vary depending on the slab thickness, expected load, environmental conditions, and specific design requirements. They should also be cut to a certain depth to ensure they are effective in controlling shrinkage.

Examples & Analogies

Consider planting trees in a garden. If you plant them too close together, they won't have enough space to grow properly and could end up competing for nutrients and space. Similarly, spacing contraction joints too closely can lead to ineffective control of cracking, while too much distance may result in uncontrolled cracks.

Key Concepts

-

Contraction Joints: Essential in controlling cracking due to shrinkage in concrete.

-

Shrinkage: Refers to the reduction in concrete volume as it hardens.

-

Structural Integrity: Importance of maintaining it through controlled cracking.

Examples & Applications

Placement of contraction joints every 10 feet in a concrete slab to manage potential shrinkage cracks.

Use of saw-cut joints in a parking lot to create predetermined crack locations.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Contraction joints help to keep cracks at bay, reducing harm as concrete curls away.

Stories

Once a concrete slab lay in the sun, it started to shrink and wanted to run. But with contraction joints wisely placed, it cracked not a bit, just stayed embraced.

Memory Tools

SABC for factors influencing contraction joints: Size, Asphalt type, Band of traffic, Climate.

Acronyms

C-SPACE

Contraction joints manage Shrinkage

Placement

Aesthetic consideration

Cracking

Environmental factors.

Flash Cards

Glossary

- Contraction Joint

A joint in concrete that is placed to control cracking due to shrinkage.

- Shrinkage

The reduction in volume of concrete as it hardens.

- Structural Integrity

The ability of a structure to withstand its intended load without experiencing failure.

Reference links

Supplementary resources to enhance your learning experience.