Warping Joints

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Warping Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss warping joints. Can anyone tell me why joints are necessary in concrete pavements?

I think they help manage the cracking that can happen due to temperature changes?

Exactly! Joints allow for expansion and contraction. Warping joints, in particular, are vital because they address the warping that occurs due to temperature gradients. What do you think happens to concrete without these joints?

It would crack and break, right?

Yes! Without the flexibility that warping joints provide, the structure could suffer significant damage. Let's remember: WJ for Warping Joints stands for 'Warping Management'.

Function of Warping Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into how warping joints function. Can anyone explain what 'warping' means in this context?

Isn’t it when the concrete bends or changes shape due to heat?

Correct! Temperature changes lead to differential expansion in the concrete's surface, causing it to warp. By incorporating warping joints, we create a controlled environment for these movements. Who remembers the types of positions these joints can take?

They can be horizontal or vertical, right?

That's right! And we strategically place them to absorb these movements effectively. WJ will hold the pavement's shape during temperature fluctuations. Remember: 'Joints do the job of keeping concrete together'.

Practical Examples of Warping Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's look at some examples where warping joints are used. Can anyone think of a situation where they would be crucial?

Maybe in highways where there are a lot of temperature variations during the day?

Absolutely! On highways, temperature changes can lead to significant warping during the day and night cycles. This necessity pushes us to design better joints. How about buildings with large concrete slabs?

Those slabs would definitely need warping joints too to handle any warping due to sun exposure.

Exactly! Whether for pavements or large slabs, we must account for warping to ensure durability. Let's repeat: 'Warping joints control the shape and integrity of structures'.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Warping joints in concrete pavements are essential for managing the effects of temperature variations that lead to slab deformation. They help maintain structural integrity by allowing for safe expansion and contraction, thus reducing the risk of cracking.

Detailed

Warping Joints

Warping joints are crucial in the construction of concrete pavements, specifically addressing the issues arising from temperature differentials that can cause slabs to warp and curl. The formation of these joints facilitates movement within the pavement, thereby enhancing the longevity and usability of the surface.

Importance

- Warping joints prevent damage by allowing slabs to change shape in response to temperature fluctuations.

- They help maintain the overall structural integrity of concrete pavements, reducing the likelihood of cracking and other failures associated with thermal expansion and contraction.

Understanding how warping joints function is fundamental for engineers and construction professionals involved in pavement design and maintenance.

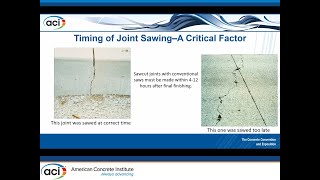

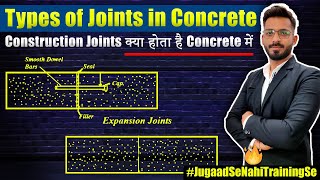

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Warping Joints

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Warping Joints: Account for warping and curling of slabs due to temperature gradients.

Detailed Explanation

Warping joints are specific types of joints in concrete pavements that are designed to accommodate the warping and curling effects caused by temperature changes. As concrete slabs heat up and cool down, they can deform. Warping joints help to manage these deformations and prevent cracks or faults in the pavement.

Examples & Analogies

Think of a long piece of metal that expands when heated. If it's constrained at both ends, it could curl or warp, potentially causing damage. Similarly, concrete slabs can bend when temperature conditions change, and warping joints allow for this movement without damage.

Importance of Warping Joints

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These joints help maintain the integrity and functionality of concrete pavements by allowing for expected movements without causing structural damage.

Detailed Explanation

The primary function of warping joints is to ensure that the concrete pavement can handle the natural movements induced by temperature variations. Without these joints, the stress from the warping could lead to significant cracking or even failure of the pavement. Therefore, they play a critical role in maintaining the longevity and durability of concrete surfaces.

Examples & Analogies

Imagine a flexible rubber band. If you pull on it too much without letting it stretch, it might snap. Warping joints act like that flexibility for concrete - they allow it to expand and contract safely, ensuring it doesn’t 'snap' under pressure.

Factors Affecting Warping

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Temperature gradients, moisture levels, and the physical properties of the concrete can influence how much warping occurs.

Detailed Explanation

Several factors influence the warping of concrete slabs. Temperature gradients play a crucial role; differences in temperature across the slab can cause uneven expansion and contraction. Additionally, moisture levels can affect the curing and strength of the concrete, impacting how it warps. Understanding these factors helps in the design of effective warping joints.

Examples & Analogies

Consider how your skin reacts to temperature changes; it can feel tight and stretch under varying conditions. Similarly, concrete responds to environmental conditions, and understanding this helps in constructing stronger, more resilient pavements.

Design Considerations for Warping Joints

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper placement and specification of warping joints are essential for optimal performance and prevention of concrete damage.

Detailed Explanation

When designing warping joints, engineers need to consider factors like joint spacing and depth to ensure they work effectively. The placement must be strategic to handle the anticipated movement, and the materials used should withstand environmental effects without degrading.

Examples & Analogies

Designing a warping joint is similar to planning a well-placed hinge on a door. If positioned wrongly, the door may not open properly. So, placing the joint in the right spots ensures that the pavement functions well while allowing for expansion and contraction.

Key Concepts

-

Warping Joints: Essential for accommodating slab deformation.

-

Temperature Gradients: Cause warping and curling in concrete.

-

Structural Integrity: Maintained through the use of warping joints to minimize cracks.

Examples & Applications

On highways, warping joints allow for the expansion and contraction of concrete slabs caused by changing temperatures throughout the day.

Large concrete parking lots utilize warping joints to manage deformations that occur due to the sun's heating effects and prevent cracking.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Warping joints make concrete slants, to keep pavement strong and not in rants.

Stories

Imagine a concrete slab in the sun all day. Without warping joints, it would crack and fray, but with them, it can grow and sway!

Memory Tools

Remember 'WARM': Warping Accommodates Reactions to Motion.

Acronyms

WJ - Warping Joints help in managing Temperature (Warps) and Cracks.

Flash Cards

Glossary

- Warping Joints

Joints that accommodate the warping and curling of concrete slabs due to temperature gradients.

- Cracking

The formation of fractures in pavement due to stress and strain.

- Temperature Gradient

The rate of temperature change in a specific direction, which can cause expansion or contraction in materials.

Reference links

Supplementary resources to enhance your learning experience.