Failure of Joint Sealants: Causes and Remedies

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Causes of Joint Sealant Failure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the causes of joint sealant failures. Who can tell me what might be a reason for this?

Could it be because of poor joint surface preparation?

Exactly! Poor joint surface preparation can lead to inadequate adhesion of the sealant. This is a significant factor in sealant failure. What about other causes?

Maybe using the wrong type of sealant material?

Correct! Using incompatible sealant materials can also result in failure. It’s crucial to match materials properly. Any other contributions?

Could incorrect sealant depth or geometry be another problem?

Yes! Incorrect dimensions can prevent proper function and lead to early failure. Now, let’s wrap this up; poor preparation, material incompatibility, and incorrect sealing dimensions are main causes.

Exploring Remedies for Sealant Failures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've identified the causes of joint sealant failures, let’s move to the remedies. What should we do if a sealant has failed?

We could clean out the failed sealant and replace it, right?

Absolutely! Cleaning the joint and replacing the sealant is crucial. What else should we consider?

Using the right backer rods and primer can help with adhesion.

Yes! Proper backing is essential for the effective sealing. Additionally, ensuring adequate curing time before allowing traffic is vital. What’s the overall message regarding maintenance?

Regular inspections can help catch issues early!

Exactly! Periodic maintenance is key to prolong the life of our sealants.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

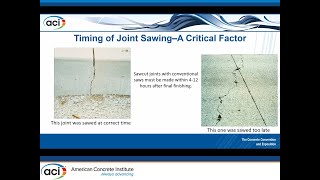

Joint sealants in concrete pavements are critical for maintaining structural integrity, but can fail due to several issues, including poor preparation and thermal overloading. This section elaborates on these causes and offers remedies such as proper sealant replacement and maintenance practices.

Detailed

This section provides an in-depth exploration of the reasons behind the failure of joint sealants in concrete pavements. It identifies key factors contributory to failure, such as poor surface preparation, material incompatibility, incorrect sealant depth, thermal or mechanical overloading, and premature exposure to traffic. To rectify these issues, remedies are suggested, including cleaning and replacing sealants, ensuring appropriate use of backing rods and primers, and adhering to curing time recommendations before allowing traffic. The significance of regular inspection and maintenance is also emphasized to prolong the life and effectiveness of joint sealants.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Causes of Joint Sealant Failure

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Poor joint surface preparation

• Incompatible sealant material

• Incorrect sealant depth/geometry

• Thermal or mechanical overloading

• Premature exposure to traffic

Detailed Explanation

This chunk identifies the various reasons why joint sealants might fail. Each point addresses specific factors that can lead to failure. For instance, poor surface preparation means that the area where the sealant is applied may have debris or moisture, preventing a strong bond. Incompatible sealant material refers to scenarios where the chosen sealant does not work well with the existing materials in the joint. If the sealant depth or geometry is incorrect, it might not accommodate joint movement well, leading to stress and eventual failure. Overloading, whether thermal expansion or mechanical stress from traffic, can exceed the sealant's design limits. Finally, exposing the sealant to traffic before it's fully set can compromise its effectiveness.

Examples & Analogies

Imagine a painter who tries to paint a wall without properly cleaning it first. If dust and grime are present, the paint won't stick well and might start peeling off. Similarly, if joint surfaces are not clean and properly prepared, the sealant won't adhere properly and may fail.

Remedies for Joint Sealant Failure

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Replacing failed sealant after cleaning joint.

• Using correct backer rods and primer.

• Ensuring correct curing time before traffic opening.

• Periodic inspection and maintenance.

Detailed Explanation

This chunk provides solutions to remedy the failure of joint sealants. The first step involves removing the failed sealant and ensuring the joint area is clean before applying a new sealant. Using correct backer rods ensures that the sealant is applied at the right depth, enhancing its effectiveness, while primers can improve adhesion. Correctly timing the curing process is crucial - if sealants are exposed to traffic too soon, they might not have developed the necessary strength. Regular inspections and maintenance can help catch any issues early, allowing for timely repairs before more extensive damage occurs.

Examples & Analogies

Consider a gardener who wants to revive a wilted plant by first removing any dead leaves and providing fresh soil and nutrients. Similarly, replaced sealants should be properly cleaned and maintained to ensure longevity and performance, just as a gardener would care for a plant to promote healthy growth.

Key Concepts

-

Poor Surface Preparation: A major cause of joint sealant failure due to improper cleaning and readying of surfaces.

-

Incompatible Sealants: Using sealants that do not match the material properties of adjacent surfaces can lead to poor performance.

-

Sealant Replacement: One of the remedies for failed joint sealants includes cleaning and replacing them cut out from the structure.

Examples & Applications

Example of poor surface preparation: A contractor fails to clean out debris from the joint, leading to sealant delamination.

Example of incompatible sealants: Using a silicone sealant in a system designed for urethane can result in deterioration.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Sealants need to be clean and bright, to bond correctly, that’s their right!

Stories

Imagine a sealant journey where it faces cleaning crews and right materials. Only with their help, it can survive traffic and weather!

Memory Tools

PRIME: Prepare, Replace, Inspect, Maintain, Ensure curing.

Acronyms

SPADE

Surface preparation

Appropriate materials

Depth check

Examination of sealants.

Flash Cards

Glossary

- Joint Sealant Failure

The breakdown or loss of integrity in a joint sealant due to various factors such as poor preparation or material incompatibility.

- Surface Preparation

The process of preparing joint surfaces to ensure optimal adhesion of sealants.

- Curing Time

The time required for sealants to set and achieve their designed performance before exposing them to traffic.

Reference links

Supplementary resources to enhance your learning experience.