Installation Techniques

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Proper Placement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s start with the installation of joint fillers. What do you think would happen if they aren’t placed correctly?

They might not fit well, causing gaps?

Exactly! Gaps can lead to water ingress, which can deteriorate pavement over time. We aim for a vertical placement that's flush with slab edges. Can anyone tell me why vertical placement might be important?

To ensure there's no extra space for water to seep in?

Correct! Keeping it flush helps prevent unintended movement. Good job!

Alignment and Gaps

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss alignment. Why do you think avoiding misalignment is crucial?

Because it could stop the filler from doing its job?

Absolutely! Misalignment can result in ineffective filling of joints, compromising their function. How can we confirm that there are no gaps?

We could measure the gaps or inspect visually?

Great ideas! Visual inspection is particularly useful. Remember, visual checks during installation are critical.

Depth of Joint Fillers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s touch on depth. Why is covering the full depth of the slab essential?

To provide enough support for expansion?

Exactly! Proper depth ensures the filler can handle thermal stresses effectively. Can anyone name what needs to be done if the depth is not as specified?

We should adjust the filler amount, right?

Correct! Adjustments are necessary to ensure it meets design intentions.

Using Bond Breakers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s discuss bond breakers. Who knows why we might use one?

To prevent the filler from sticking to the concrete?

Exactly! By using a bond breaker, we can allow natural movement of the filler without risking damage. Why is that important for the lifespan of the pavement?

Because it helps the filler stay effective longer?

Right again! Ensuring effective performance over time is essential for maintaining structural integrity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Proper installation techniques for joint fillers are vital to maintain the efficacy of concrete pavements. This involves placing the filler correctly, ensuring no gaps exist, and using bond breakers as necessary to prevent adhesion.

Detailed

Installation Techniques for Joint Fillers

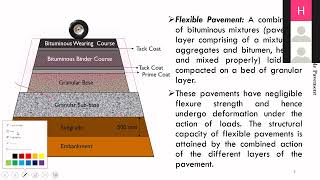

In this section, we will discuss various techniques essential for the correct installation of joint fillers in concrete pavements. These techniques play a critical role in ensuring that joint fillers function effectively to accommodate movement due to temperature fluctuations and prevent water ingress, which could lead to pavement deterioration. This involves:

- Placement Orientation: Fillers should be placed vertically and flush with the slab edges to provide a seamless fit.

- Alignment Checks: It is essential to avoid gaps or misalignments during placement, as distortions can compromise joint performance.

- Depth Compliance: The filler must cover the full depth of the slab, or be installed according to design specifications, ensuring adequate support.

- Use of Bond Breakers: In instances where adhesion to concrete is a concern, bond breakers can be applied to facilitate necessary movement without risking damage or disintegration of the filler.

These techniques ensure that joint fillers remain effective throughout the life of the pavement, accommodating thermal expansion and contraction while protecting the structural integrity of the concrete.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Placement of Joint Fillers

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Should be placed vertically, flush with slab edges.

Detailed Explanation

Joint fillers must be installed in a vertical orientation, meaning they should stand upright in the joint gap. Additionally, when we say they should be 'flush with slab edges', we mean that the top edge of the filler should align perfectly with the surface of the concrete slabs. This ensures that the filler is properly seated in the joint and helps prevent any water or debris from entering the joint.

Examples & Analogies

Imagine placing a book in a shelf that is just the right size. If you don’t place it flush with the edge, it might stick out, causing other books to get damaged or the shelf to become uneven. Similarly, joint fillers need to be flush with slab edges to maintain a clean and effective surface.

Avoiding Gaps and Misalignments

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

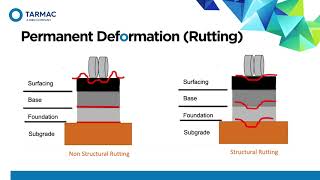

Care must be taken to avoid gaps or misalignments.

Detailed Explanation

When installing joint fillers, precision is crucial. Gaps or misalignments can occur if the filler is not placed accurately. These irregularities can allow water and debris to infiltrate the joint, leading to deterioration over time. Proper alignment ensures that the filler can perform its function effectively, maintaining the integrity of the concrete pavement.

Examples & Analogies

Think of it like assembling a puzzle. If one piece is slightly out of place, it can disrupt the entire picture and leave spaces that shouldn't be there. In the same way, if joint fillers are misaligned, it can create weaknesses in the pavement.

Depth of Installation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Should cover the full depth of slab (or as per design).

Detailed Explanation

The joint filler must be installed to the design specifications for depth, meaning it should fill the joint completely or according to the planned specifications provided by engineers. This helps absorb movement and maintains the joint's functionality. If not deep enough, the filler might not provide the needed support during expansion or contraction, leading to issues in pavement integrity.

Examples & Analogies

Imagine trying to fill a deep hole with just a little dirt—it won’t do the job well. Similarly, if the joint filler is not deep enough, it won't effectively manage the concrete slab movements, leading to potential failures.

Use of Bond Breakers

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bond breakers may be used to avoid adhesion with concrete.

Detailed Explanation

Bond breakers are materials used during installation to ensure that the joint filler does not stick to the surrounding concrete. By preventing adhesion, bond breakers allow the filler to move freely within the joint space as the concrete expands and contracts. This movement is critical for the performance of the joint filler, as it needs to accommodate shifting without being hindered by the concrete itself.

Examples & Analogies

Think of baking a cake in a pan. If you don’t use a non-stick spray, the cake will stick to the pan and break apart when you try to remove it. Bond breakers serve a similar purpose by allowing the filler to move without sticking to the concrete surrounding it.

Key Concepts

-

Vertical Placement: Ensures that no excess space is present for water entry.

-

Flush with Slab Edges: Helps maintain structural integrity and prevents misalignment.

-

Depth Coverage: Essential for adequate support against thermal expansion.

-

Bond Breakers: Critical for allowing joint movement without filler adhesion.

Examples & Applications

Using bituminous premoulded fillers correctly ensures effective sealing and expansion control.

Improper placement of joint fillers can lead to significant long-term damage in concrete pavements.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If your filler does not fit, it’s a sure sign of grit; flush it right and tight, keep the pavement bright!

Stories

Once upon a time in the land of Concreteville, the pavement needed strong fillers to withstand time’s will. The wise builders knew, alignment was key, ensuring every gap was filled perfectly, you see.

Memory Tools

Remember ‘VFGD’ - Vertical placement, Full depth, Gaps avoided, and the use of Bond breakers.

Acronyms

Use ‘JVFB’ to remember

Joint Fillers

Vertically placed

Flush with edges

Bond breakers used.

Flash Cards

Glossary

- Joint Filler

Compressible materials inserted in a joint gap to accommodate the expansion of concrete slabs.

- Bond Breakers

Materials used to prevent adhesion between fillers and concrete, allowing for joint movement.

- Flush Placement

Fitting the joint filler flush with the concrete slab edges for seamless integration.

- Misalignment

Improper alignment of fillers that can lead to gaps impacting functional integrity.

Reference links

Supplementary resources to enhance your learning experience.