Joint Fillers and Sealers in Concrete Pavements

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Joint Fillers and Sealers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome, class! Today, we will learn about joint fillers and sealers for concrete pavements. Can anyone tell me why we need these components in our pavements?

They help prevent cracking, right?

Exactly! Concrete is strong but can crack due to thermal expansions and other factors. Filler materials accommodate these movements. Let's remember: Fillers help 'fill the gap.' Now, what about sealers?

They keep water and debris out?

Right! Sealers protect the inside of the joint. Together, fillers and sealers ensure durability. It's crucial to maintain them. Can anyone tell me why maintenance is necessary?

To avoid more expensive repairs later!

Absolutely, Smart thinking! Remember: 'Protect and Inspect' for lasting pavements.

Types of Joints in Concrete Pavements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into joint types! Can anyone name the types of joints we've discussed?

Um, expansion joints and contraction joints?

Great start! Expansion joints allow movement from thermal changes, while contraction joints aim to control crack locations. Who can tell me about construction or warping joints?

Construction joints are where work pauses, right? And warping joints handle twisting and curling?

Spot on! Each joint serves a specific purpose. Here's a mnemonic: 'E-C-C-W' - Expansion, Contraction, Construction, Warping. Can anyone think of why these specifications matter?

Different loads and climates could change how each joint performs?

Exactly! Understanding these joints helps us choose the correct fillers and sealers.

Joint Fillers: Properties and Materials

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's explore joint fillers! What properties should we look for?

High compressibility and recovery after compression?

Correct! Fillers must be durable and resist water. Can anyone name some common materials?

Um, cork and bituminous premoulded fillers?

Right again! Cork is natural and durable, while bituminous fillers are quite popular. Remember: ‘Cork and Bitumen - a filling duet!’ Let's discuss installation next.

How do we install these fillers?

Good question! They need to be flush with the slab edges, right? Always ensuring no gaps. This helps with their performance.

Joint Sealers: Functions and Types

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s examine joint sealers. What do we aim for when applying sealants?

To prevent water and debris entering the joints?

Exactly! Sealers prevent damage and protect against environmental attacks as well. Can you differentiate between hot-poured and cold-poured sealants?

Hot-poured is heated before application, while cold-poured is applied at ambient temperature?

Spot on! Hot-poured sealants are often more durable. A rule of thumb to remember: 'Heat for strength!' Compare that to cold-poured which is easier to apply. Can anyone see any advantages?

Cold-poured sealants have a longer shelf life, right?

Exactly! Both types serve unique purposes according to project needs. Be sure to select wisely!

Maintenance and Recent Advances

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why is regular maintenance for joint fillers and sealers important?

To catch problems before they become worse!

Exactly! Regular inspection can save costs. Have any of you heard about advancements in this field?

I read about self-healing materials!

Great point! These innovations can significantly increase longevity. Also, nano-modified fillers are another exciting area. Remember this: 'Innovation in protection leads to longevity!'

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Concrete pavements require joints to manage cracking and structural integrity due to temperature changes, shrinkage, and expansion. Joint fillers are compressible materials that allow for slab expansion while sealers protect against water and debris. Proper selection, installation, and maintenance of these materials are vital for long-lasting pavement performance.

Detailed

Joint Fillers and Sealers in Concrete Pavements

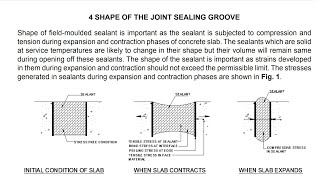

Concrete pavements have significant load-bearing capabilities but are prone to cracking due to thermal variations, shrinkage, and expansion. To mitigate these issues, various types of joints, such as expansion, contraction, construction, and warping joints, are employed.

Joint Fillers

Joint fillers serve to accommodate the expansion of concrete slabs and prevent the intrusion of harmful materials. Desirable characteristics include high compressibility, durability, and resistance to water absorption. Common filler materials include bituminous premoulded fillers, cork, sponge rubber, cellulose fiberboard, and expanded polystyrene.

Joint Sealers

Applied to seal joints, sealers prevent water and debris damage while allowing for structural movement. They can be categorized into hot-poured and cold-poured sealants, with distinct behaviors and application techniques. Ideal sealers have excellent adhesion, elasticity, and resistance to environmental factors.

Installation practices for both fillers and sealers are essential to their effectiveness, including proper joint preparation, backer rod placement, and adherence to application guidelines. Regular maintenance and addressing sealant failures is critical for extending the service life of pavement joints.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Joint Fillers and Sealers

Chapter 1 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Concrete pavements, despite their rigidity and high load-bearing capacity, are susceptible to cracking and damage due to temperature variations, shrinkage, and expansion. To control these movements and maintain structural integrity, joints are provided in concrete pavements. These joints must be adequately protected to prevent the ingress of water, debris, and incompressible materials that can lead to pavement deterioration.

Joint fillers and sealers serve as essential components in the performance and durability of concrete pavements. Fillers are used to provide space for expansion, while sealers prevent entry of unwanted materials and ensure watertightness. Proper design, material selection, and maintenance of joint fillers and sealers are crucial for long-lasting pavement performance.

Detailed Explanation

This chunk introduces the concept of joint fillers and sealers in concrete pavements. Concrete, while strong, can crack and damage due to various factors like temperature changes and natural shrinking. To manage this issue, joints are incorporated into the pavement. These joints need protection against unwanted elements, such as water and debris, which can deteriorate the pavement over time. Joint fillers provide necessary space for the concrete to expand and contract, while sealers block the entrance of harmful materials, ensuring waterproof integrity. Selecting the right materials and maintaining these joints are essential for the longevity of the pavement.

Examples & Analogies

Think of a concrete pavement like a well-made suit. Just as a suit has seams that allow for movement while keeping it tailored, concrete pavements have joints that allow for expansion and contraction due to temperature changes. Without proper care for these seams—like cleaning, sealing, and maintaining them—the suit can start to fray and fall apart, just as pavements can crack and deteriorate without joint care.

Types of Joints in Concrete Pavements

Chapter 2 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Before understanding fillers and sealers, it's important to know the different types of joints in concrete pavements:

• 18.2.1 Expansion Joints: Allow for thermal expansion of concrete.

• 18.2.2 Contraction Joints: Control the location of cracking due to shrinkage.

• 18.2.3 Construction Joints: Placed where construction is stopped and continued later.

• 18.2.4 Warping Joints: Account for warping and curling of slabs due to temperature gradients.

Detailed Explanation

This chunk describes the four primary types of joints found in concrete pavements. Expansion joints are specifically designed to allow the concrete to expand due to heat, preventing cracking. Contraction joints, on the other hand, help manage where cracks may occur from the natural shrinkage of concrete as it sets. Construction joints are implemented where work needs to stop and resume later, ensuring a seamless connection between pavement sections. Finally, warping joints accommodate the warping effect, where slabs may curl due to temperature differences across their surface, ensuring these physical changes do not compromise the pavement's integrity.

Examples & Analogies

Imagine a large rubber band. If you pull it in different directions, it stretches and can return to its original shape. That’s similar to how expansion joints work; they let the pavement stretch without cracking. Now, think of a balloon. If you blow it up too quickly, it can pop—like how contraction joints help manage shrinking before cracks form. Having construction joints is like having a pause in a long line of dominoes; it allows you to add more without upsetting the line. Warping joints are like the bends in a winding road, helping to manage changes in surface levels across different temperatures.

Joint Fillers

Chapter 3 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Joint fillers are compressible materials inserted in the joint gap to accommodate the expansion of concrete slabs. They remain in place throughout the pavement's life, absorbing compressive forces without disintegrating.

Detailed Explanation

This chunk explains what joint fillers are and their critical role in maintaining the pavement’s structure. Joint fillers are soft materials placed in the gaps between concrete slabs to allow room for movement caused by temperature and weight. They are designed to withstand constant pressure without breaking down, hence supporting the structure over its lifespan. Filler materials compress when the slabs expand but spring back when the slabs contract, effectively managing the dynamic forces acting on the pavement.

Examples & Analogies

Consider joint fillers like the cushion in a shoelace. Just as the cushioned areas allow the shoelace to tighten without snapping, joint fillers give room for concrete to expand and contract without risking cracks. They absorb shock much like how cushions absorb force, making the entire system more resilient.

Desirable Properties of Joint Fillers

Chapter 4 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• High compressibility

• Recovery after compression

• Resistance to extrusion

• Durability under environmental conditions

• Non-absorbent or low water absorption

• Resistance to rot or biological degradation

Detailed Explanation

This chunk lists the desirable properties that make an effective joint filler. High compressibility is crucial for accommodating changes in joint size, while recovery ensures that the filler returns to its original shape after compressive forces are removed. Resistance to extrusion is important to keep the filler in place during movements. Durability ensures that fillers withstand environmental effects without degrading. Low water absorption is essential to prevent filler deterioration, and resistance to rot is necessary to ensure longevity against biological threats.

Examples & Analogies

Think of a good joint filler like a high-quality sponge. A sponge should be able to compress when you press it but bounce back to its original shape when released. It should resist tearing and not absorb water permanently to stay clean. Similarly, a joint filler needs to fit snugly, withstand the weather, and resist breaking down, like a sponge that doesn’t fall apart after being used in water.

Common Materials Used as Joint Fillers

Chapter 5 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Bituminous Premoulded Fillers: Made from bitumen and fibers, common in India.

• Cork: Natural, compressible, and durable.

• Sponge Rubber or Foam Sheets: Light, easy to install, and highly compressible.

• Cellulose Fiberboard: Impregnated with bitumen for waterproofing.

• Expanded Polystyrene (EPS): Lightweight and resilient.

Detailed Explanation

This chunk presents various materials used as joint fillers, highlighting their unique characteristics and uses. Bituminous premoulded fillers, made from bitumen mixed with fibers, are prevalent due to their compressive qualities. Cork is a natural material prized for its compressibility and durability. Sponge rubber or foam sheets are lightweight options that are easy to handle and install while providing excellent compression. Cellulose fiberboard, treated with bitumen, offers water resistance, and Expanded Polystyrene (EPS) is recognized for its lightweight and resilient nature, making it suitable for diverse conditions.

Examples & Analogies

Choosing the right filler material is like selecting the right foam for a mattress. Just as some people prefer the support of memory foam while others need the natural feel of latex, the pavement needs specific fillers to match its conditions, from robust materials like cork and bitumen to lighter options like foam for flexibility and ease of installation.

Installation Techniques for Joint Fillers

Chapter 6 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Should be placed vertically, flush with slab edges.

• Care must be taken to avoid gaps or misalignments.

• Should cover the full depth of slab (or as per design).

• Bond breakers may be used to avoid adhesion with concrete.

Detailed Explanation

This chunk outlines the critical installation techniques for joint fillers. Proper placement is vital; fillers should be positioned vertically and flush with the edges of the slab to seal effectively. Avoiding gaps or misalignments is crucial to ensure the filler can perform its role without compromising the joint. The filler should cover the full depth of the joint as per design requirements to provide adequate support. Using bond breakers can help prevent the filler from sticking to the concrete, allowing for necessary movement.

Examples & Analogies

Think of installing joint fillers like laying tiles on a floor. Just as it's important to place the tiles evenly and ensure they sit flush against each other without gaps, joint fillers need careful positioning to work effectively. If tiles are misaligned or have spaces, the floor may crack; similarly, poorly installed fillers can lead to joint failure.

Purpose and Function of Joint Sealers

Chapter 7 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Joint sealers are applied to seal the joint opening and prevent the ingress of water, fine particles, sand, and other debris. They protect the joint from environmental attacks and mechanical damage.

Detailed Explanation

This chunk focuses on the purpose of joint sealers. Joint sealers are crucial for protecting joints from water and debris that can cause issues like cracking and deterioration. By creating a watertight seal, they help to maintain the integrity of the concrete pavement. Additionally, they serve to protect against environmental factors and mechanical damage, ensuring the lifespan of the pavement is extended.

Examples & Analogies

Imagine joint sealers as the raincoat for concrete pavements. Just like a raincoat keeps you dry by sealing out water and keeping out dirt, joint sealers safeguard joints from moisture and debris, protecting the 'health' of the pavement so it can last longer.

Functions of Joint Sealants

Chapter 8 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Prevent water seepage into the sub-grade

• Allow joint movement due to temperature changes

• Resist ingress of incompressibles

• Minimize spalling at joint faces

• Reduce noise from joint impact

Detailed Explanation

This chunk outlines the various functions of joint sealants. The primary role is to stop water from moving into the subgrade, which could lead to structural issues. Sealants also allow for expansion and contraction due to temperature changes, ensuring the pavement can move without cracking. They resist the entry of materials that don't compress, minimize surface damage, and reduce noise from impacts on the joints, enhancing both functionality and user satisfaction.

Examples & Analogies

Think of joint sealants as a flexible shield for a quiet library. Just as the library's soundproofing materials absorb noise and prevent distractions while allowing people to walk around freely, joint sealants help manage the movements of concrete while keeping out damaging elements like water and dirt, ensuring the pavement remains functional and resilient.

Classification of Joint Sealants

Chapter 9 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

(a) Based on Application Type

• Hot-poured Sealants: Bitumen-based or rubberized asphalt, heated before application.

• Cold-poured Sealants: Polysulfide, silicone, polyurethane – applied without heating.

(b) Based on Material Behavior

• Elastomeric Sealants: Flexible, stretchable, and return to original shape.

• Plastomeric Sealants: Non-elastic but can deform under load.

Detailed Explanation

This chunk categorizes joint sealants based on their application type and material behavior. Hot-poured sealants, made from heated bitumen or rubber, offer a robust sealing option when applied. Cold-poured sealants, made from various polymers applied at ambient temperatures, serve as a more convenient alternative. Additionally, elastomeric sealants provide flexibility and can return to their original shape after deformation, while plastomeric sealants maintain a set shape but can deform under stress, allowing for different applications and conditions.

Examples & Analogies

Choosing between hot-poured and cold-poured sealants can be likened to choosing cooking methods. Just as you might prefer grilling or baking depending on the dish, the method of sealing is selected based on the environmental conditions and material properties needed for joint health and durability.

Requirements of Ideal Joint Sealants

Chapter 10 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Good adhesion to concrete

• High elasticity and extensibility

• Low modulus to accommodate joint movement

• Durability against UV rays, weather, oil, and chemicals

• Resistance to aging and embrittlement

• Easy to apply and maintain

Detailed Explanation

This chunk outlines the ideal characteristics of effective joint sealants. They should adhere well to the concrete to prevent leaks, while elasticity allows them to stretch without breaking. A low modulus helps accommodate movement in the joints. Sealants must also withstand various environmental factors, including UV radiation and chemicals, ensuring they don’t degrade prematurely. Additionally, ease of application and maintenance is important for practical efficiency in real-world applications.

Examples & Analogies

Think of ideal joint sealants like a good pair of running shoes. They need to fit perfectly (adhesion), be flexible to absorb impacts (elasticity), withstand different weather conditions (durability), and be easy to clean (maintain). Just as you wouldn’t run in shoes that are uncomfortable or fall apart easily, choosing the right sealants is crucial for the longevity and performance of concrete pavements.

Comparison: Hot-Poured vs Cold-Poured Sealants

Chapter 11 of 11

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Property Hot-Poured Sealants Cold-Poured Sealants

Application High (150–200°C) Ambient Temperature

Flexibility Lower High

Cure Time Immediate after cooling Requires curing (few hours)

Shelf Life Short (once heated) Long (pre-mixed in tubes)

Durability Moderate High

Cost Low Comparatively higher

Detailed Explanation

This chunk compares hot-poured and cold-poured sealants across several dimensions: application temperature, flexibility, cure time, shelf life, durability, and cost. Hot-poured sealants require heating, making them less flexible, while cold-poured sealants can be applied at ambient temperatures, offering more flexibility. The curing time for hot-poured sealants is immediate after they cool down, contrasting with the longer curing time needed for cold-poured sealants. In terms of durability, cold-poured sealants typically last longer and often come at a higher cost.

Examples & Analogies

Choosing between hot-poured and cold-poured sealants is like choosing between instant and gourmet meals. Hot-poured is quick, requiring the heat of cooking but not as flexible in use—similar to a quick microwave meal. Cold-poured is more versatile, much like a gourmet dinner that's prepared with more time and quality but is usually a bit costlier.

Key Concepts

-

Joint Fillers: Materials used to absorb concrete expansion.

-

Joint Sealers: Protect joints from moisture and debris.

-

Types of Joints: Different joints accommodate various movements in concrete.

Examples & Applications

An example of an expansion joint is found in highway concrete pavements where temperature changes significantly affect slab size.

A practical application of cold-poured sealants can be seen in residential driveways to avoid the cost of heating equipment.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Fillers fill it right, keep concrete light; Sealers keep it tight, through day and night.

Stories

Imagine a new road being built during summer. The sun heats the concrete, making it expand. Fillers are there to allow this expansion without cracking the road. Sealers then step in, ensuring nothing harmful can enter the joints. Together, they create a sturdy path for cars!

Memory Tools

FILL for Joint Fillers: F – Fundaments (to hold), I – Insert (in gaps), L – Light (compressible), L – Long-lasting (durable).

Acronyms

SEALS for Joint Sealants

– Shield (against water)

– Elastic (to allow movement)

– Adhere (well to surfaces)

– Long-lasting (performance)

– Safe (from debris).

Flash Cards

Glossary

- Joint Fillers

Compressible materials placed in joints to accommodate expansion.

- Joint Sealers

Materials applied to joints to prevent water and debris ingress.

- Expansion Joints

Joints designed to allow thermal expansion of concrete.

- Contraction Joints

Joints that control where cracking due to shrinkage will occur.

- HotPoured Sealants

Sealants applied in a heated state for maximum adhesion.

- ColdPoured Sealants

Sealants applied at ambient temperature without heating.

Reference links

Supplementary resources to enhance your learning experience.