Joint Sealers

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Purpose and Function of Joint Sealers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing joint sealers. Can anyone tell me why we use joint sealers in concrete pavements?

They prevent water from getting into the joints?

Yes, exactly! They also prevent debris from entering. In fact, these sealers help protect the joint faces from environmental damage. This is crucial for maintaining the integrity of the pavement. Can someone share another function?

Do they help with joint movement too?

Correct! They allow for the natural movement due to temperature changes. This leads us to the various types of sealants. One memory aid here is 'PEAR'—Preventing Environmental Attack and Resisting debris.

What happens if the sealers fail?

Great question! We will cover that later. But remember, a well-functioning sealer is vital for pavement longevity.

Can sealers also reduce noise?

Exactly! Depending on the material used, sealers can help minimize noise caused by traffic impact. Let’s summarize: joint sealers help prevent water and debris entry, accommodate movement, and reduce noise.

Classification of Joint Sealants

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's classify different types of joint sealants. Can anyone name a type based on how they're applied?

Hot-poured sealants!

Exactly! Hot-poured sealants are heated before application. What about another type?

Cold-poured sealants?

Right again! These are applied at ambient temperatures. Let’s remember the acronym 'HCC' for Hot and Cold sealants. What about their material behavior?

Elastomeric and plastomeric sealants?

Perfect! Elastomeric sealants are flexible and can return to their original shape, while plastomeric cannot. It's essential to choose the right sealant based on these characteristics.

Requirements of Ideal Joint Sealants

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss what makes an ideal joint sealant. Can anyone list some key properties?

Good adhesion to concrete?

Yes, that's critical! What else?

They should be elastic and durable?

Absolutely! They need to withstand UV rays, weather, and chemicals. A simple mnemonic here could be 'ADAPT': Adhesion, Durability, Adaptability, Performance, and Temperature resistance.

How do we ensure these properties are maintained?

Regular inspections and appropriate application techniques are key!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Joint sealers are applied to concrete pavement joints to prevent water, fine particles, and other debris from entering, thereby protecting joints against environmental and mechanical damage. They must possess specific properties to ensure durability and effectiveness in the face of joint movement.

Detailed

Joint Sealers: An In-Depth Overview

Joint sealers are materials used to seal the openings of joints in concrete pavements, serving a protective role against moisture, debris, and mechanical damage. They are crucial in ensuring the longevity and performance of concrete pavements by fulfilling several vital functions, including:

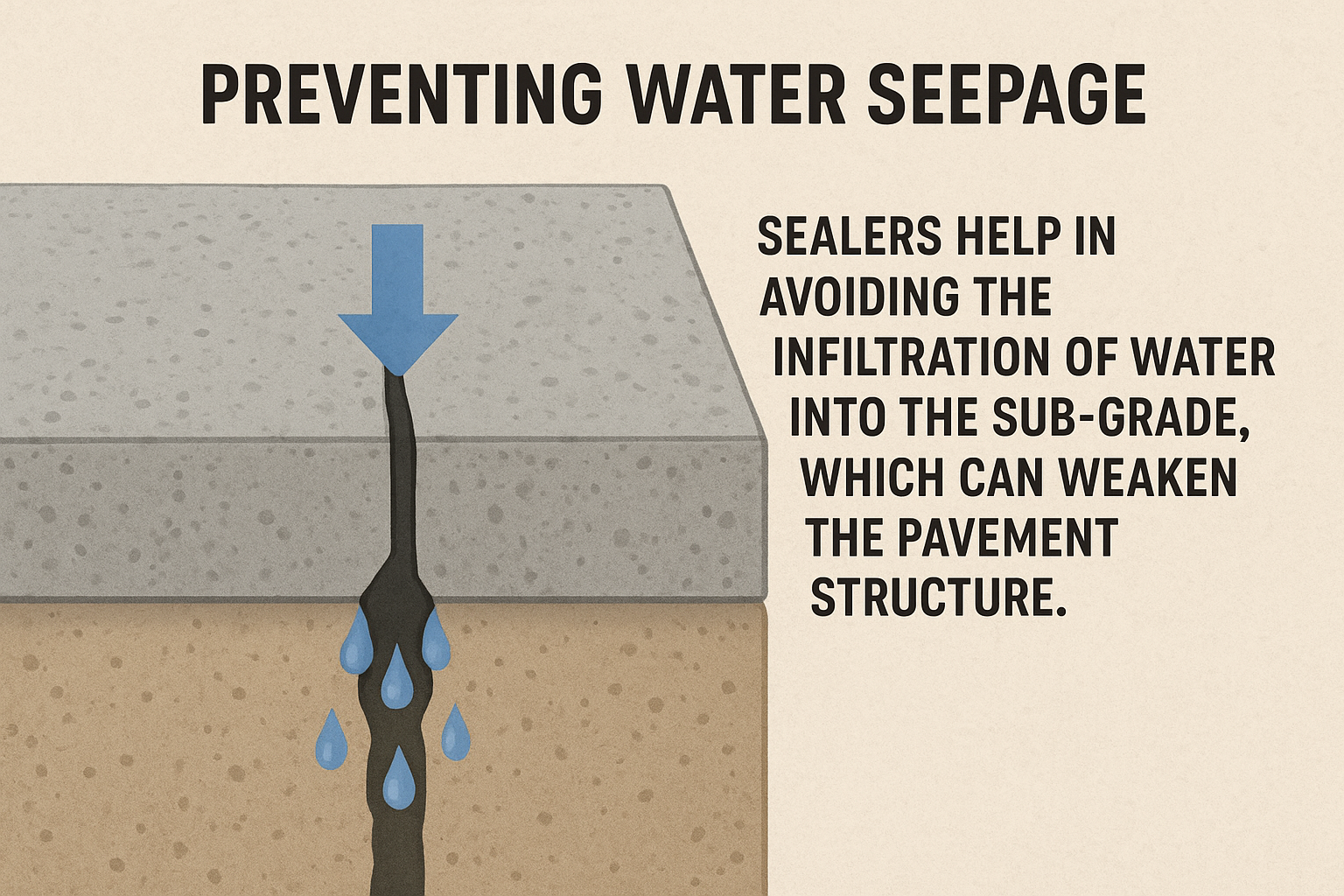

- Preventing Water Seepage: Sealers help in avoiding the infiltration of water into the sub-grade, which can weaken the pavement structure.

- Accommodating Joint Movement: They are designed to adapt to the natural movements of the joints occurring due to temperature fluctuations.

- Resisting Ingress of Incompressibles: Effective sealers prevent materials like sand or dirt from entering the joints, which could lead to structural issues.

- Minimizing Joint Face Spalling: By protecting the joint faces, sealers help in reducing the wear and tear that causes spalling.

- Noise Reduction: Sealants can also help in decreasing noise generated from traffic on the joints.

Classification and Properties

Joint sealants are classified based on their application method (hot-poured vs. cold-poured) and behavior (elastomeric vs. plastomeric). Ideal sealants exhibit good adhesion, high elasticity, low modulus for joint movement accommodation, resistance to environmental factors, and ease of application.

The section concludes with practical considerations for installation, design, and the common causes of sealant failure, along with necessary remedies to prolong the life of the joint sealers.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose and Function of Joint Sealers

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Joint sealers are applied to seal the joint opening and prevent the ingress of water, fine particles, sand, and other debris. They protect the joint from environmental attacks and mechanical damage.

Detailed Explanation

Joint sealers are important materials used in concrete pavements. Their main purpose is to fill the joint openings, which helps to keep out harmful substances like water, dirt, and small particles. This sealing function is crucial for preventing damage from environmental factors, such as rain or snow, and mechanical factors, like traffic stress. By effectively sealing the joints, sealers help to preserve the integrity of the pavement over time.

Examples & Analogies

Think of joint sealers like a waterproof jacket for concrete. Just as a jacket protects you from getting wet in the rain, joint sealers prevent water and other damaging materials from getting into the joints of the pavement.

Functions of Sealants

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Prevent water seepage into the sub-grade

• Allow joint movement due to temperature changes

• Resist ingress of incompressibles

• Minimize spalling at joint faces

• Reduce noise from joint impact

Detailed Explanation

Sealants serve multiple functions: They stop water from leaking into the layers beneath the pavement, which is essential to maintain the structural support for the concrete. Additionally, they allow for the natural movement of joints caused by temperature changes; this is important because concrete expands and contracts with heat and cold. Sealants also help prevent materials that can’t be compressed (like rocks) from getting into the joints, which could cause issues. Moreover, they help to reduce spalling, which is when the surface of the concrete starts to chip or flake off, particularly at the edges of joints. Finally, they can lessen the noise generated when vehicles drive over the joints.

Examples & Analogies

Imagine trying to keep a door in your house from making noise when it swings open and shut. If you apply a rubber seal around it, it not only creates a quieter environment but also keeps out dirt and dust. Similarly, joint sealers keep joints clean and quiet, while allowing necessary movement.

Classification of Joint Sealants

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Joint sealants can be classified in two main ways:

(a) Based on Application Type

• Hot-poured Sealants: Bitumen-based or rubberized asphalt, heated before application.

• Cold-poured Sealants: Polysulfide, silicone, polyurethane – applied without heating.

(b) Based on Material Behavior

• Elastomeric Sealants: Flexible, stretchable, and return to original shape.

• Plastomeric Sealants: Non-elastic but can deform under load.

Detailed Explanation

Joint sealants can be categorized into two types based on their application and their behavior under stress. The first classification is by how they are applied; hot-poured sealants need to be heated before they can be used, while cold-poured sealants can be applied directly at room temperature. The second classification depends on the behavior of the materials. Elastomeric sealants are very flexible and can stretch significantly, returning to their original shape after deformation. Plastomeric sealants, on the other hand, are not elastic but can still change shape when a load is applied, though they do not return to the original form.

Examples & Analogies

Think of hot-poured sealants like melted chocolate that you pour when it's warm—once it cools, it hardens and holds everything together. On the other hand, cold-poured sealants can be likened to a smooth frosting you can spread directly onto a cake without needing to heat it up. Both types have unique properties and uses depending on how they are engineered.

Requirements of Ideal Joint Sealants

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Good adhesion to concrete

• High elasticity and extensibility

• Low modulus to accommodate joint movement

• Durability against UV rays, weather, oil, and chemicals

• Resistance to aging and embrittlement

• Easy to apply and maintain

Detailed Explanation

For a sealant to perform well, it must meet several important criteria. It needs to bond effectively with concrete so that it can effectively seal the joints. High elasticity and extensibility are crucial because sealants must stretch and move without breaking as the pavement shifts with temperature changes. A low modulus is needed to allow easy movement in the sealant itself without putting pressure on the joint. Sealants also need to be durable and resistant to various environmental factors, such as sunlight (UV rays), varying weather conditions, oils, and chemicals that could degrade the material over time. They should not break down as they age, and it should be straightforward to apply and maintain them.

Examples & Analogies

Imagine trying to use a rubber band that just doesn't stretch or bounces back; it won't hold things together effectively. Similarly, the ideal joint sealant must be like a quality rubber band that can adapt to changes without losing its effectiveness, while also being strong enough to withstand outside conditions.

Key Concepts

-

Purpose and Function: Joint sealers prevent moisture and debris from entering concrete joints, protecting against damage.

-

Classification: Sealants can be hot-poured or cold-poured, elastomeric or plastomeric.

-

Ideal Properties: Effective sealants should have good adhesion, elasticity, low modulus, and resist environmental factors.

Examples & Applications

An elastomeric sealant that maintains flexibility and adapts to joint movements over time is ideal in regions with extreme temperature changes.

In urban areas with heavy vehicle traffic, hot-poured sealants are often used due to their lower cost and durability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Seal the joint to keep it tight, prevent the damage, keep it right.

Stories

Imagine a city where roads are always wet and mixed with debris; the pavements need shielded joints like superheroes to stay strong and long-lasting.

Memory Tools

Remember 'ADAPT': Adhesion, Durability, Adaptability, Performance, Temperature resistance for sealant properties.

Acronyms

PEAR

Preventing Environmental Attack and Resisting debris for sealers.

Flash Cards

Glossary

- Joint Sealers

Materials used to seal joints in concrete pavements to prevent moisture and debris ingress.

- Elastomeric Sealants

Flexible sealants that can stretch and return to their original shape.

- Plastic Sealants

Sealants that are non-elastic but can deform under load.

- HotPoured Sealants

Sealants that are heated before application for better flow and adhesion.

- ColdPoured Sealants

Sealants that are applied at ambient temperatures without heating.

Reference links

Supplementary resources to enhance your learning experience.