Placement in VLSI Design

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Objectives of Placement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to explore the key objectives of placement in VLSI design. Can anyone tell me what we aim to achieve during this step?

To minimize delay and power consumption?

That's correct! Minimizing delay ensures that signals can travel quickly between cells. Reducing power consumption is also crucial. Can anyone explain how these objectives relate to each other?

If we minimize the length of the connections, we can reduce both delay and power consumption.

Exactly! By keeping the connections short, we not only enhance performance but also save energy. Now, in addition to those, what else should we consider in placement?

Meeting timing constraints?

Yes! It's vital to ensure that we meet the setup and hold times for all signals. Summarizing, the objectives of placement are to minimize delay, reduce power consumption, meet timing constraints, and maximize area efficiency.

Placement Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's talk about the two main types of placement: global and detailed. Student_4, could you explain what global placement is?

Global placement is about arranging cells across the entire chip to minimize overall wirelength, right?

Exactly! And what about detailed placement? Student_1?

Detailed placement fine-tunes the positions of the cells to meet specific constraints like timing and signal integrity.

Great! Detailed placement is indeed about ensuring every cell is perfectly positioned. Why do you think both types are important?

They both work together to optimize the design. Global placement sets a broad basis while detailed placement perfects it.

Perfectly summarized! Always remember, the interplay between global and detailed placement is essential for optimal designs.

Placement Algorithms

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s delve into some placement algorithms. Who can give an overview of what simulated annealing is?

It's a probabilistic approach that adjusts cell placements over time to minimize wirelength and optimize performance.

Excellent! And what about force-directed algorithms, Student_4?

They use modeling forces to adjust placement. Cells are attracted or repelled to reach optimal positions.

Right! Such algorithms can effectively minimize congestion. Can anyone explain why we might use greedy algorithms?

They are faster but may not provide the best global solution, which can be a trade-off.

Exactly! It’s all about balancing speed and optimal solutions. Understanding these algorithms is crucial for effective placement.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the crucial step of placement following floor planning in VLSI design, which aims to minimize delay, power consumption, and chip area while ensuring functional specifications are met. Key techniques and algorithms used for effective placement are also covered.

Detailed

Placement in VLSI Design

In VLSI design, placement is a critical phase that follows the initial floor planning step. It involves positioning individual cells or standard blocks within the predefined floor plan to meet various design objectives. The primary aims of this stage include minimizing signal delay, reducing power consumption, meeting timing constraints, and maximizing area efficiency.

Objectives of Placement

The core goals of placement include:

- Minimizing Delay: This ensures that signals travel through the shortest possible path between cells, reducing propagation delay.

- Reducing Power Consumption: Minimizing the length of interconnects can lead to significant reductions in both dynamic and static power usage.

- Meeting Timing Constraints: Critical paths need to be optimized to ensure that setup and hold times are met.

- Maximizing Area Efficiency: Effective placement aims to fully utilize chip area and avoid congestion.

Placement Techniques

Placement can be categorized into global and detailed placement:

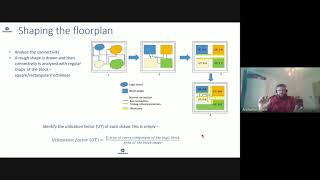

- Global Placement: This step involves an initial broad placement across the entire chip, focusing on minimizing total wirelength and improving timing performance.

- Detailed Placement: This refinement process adjusts the positions of cells to satisfy more specific constraints, such as timing and signal integrity.

Placement Algorithms

Several algorithms aid in the placement process:

- Simulated Annealing: A probabilistic method that iteratively adjusts placements for optimization.

- Force-Directed Algorithms: These model placements as a system of forces pushing and pulling cells to their optimal positions.

- Greedy Algorithms: These place cells based on local optimization, often leading to faster but less globally optimal solutions.

Placement Tools

Tools commonly used in the industry for placement include:

- Cadence Innovus: It automates placement with a focus on timing, power, and area.

- Synopsys IC Compiler II: Offers advanced capabilities for large designs.

- OpenROAD: An open-source solution that automates placement balancing timing and area constraints.

In summary, proper placement is vital for the efficiency and performance of VLSI designs, utilizing various techniques and tools to achieve an optimal layout.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Objectives of Placement

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The main goals of placement include:

● Minimizing Delay: Ensuring that signals travel through the shortest possible path between cells, reducing signal propagation delay and improving the timing of the design.

● Reducing Power Consumption: Minimizing the length of power and signal interconnects can reduce both dynamic and static power consumption.

● Meeting Timing Constraints: Placement is crucial for ensuring that critical paths are optimized to meet the required setup and hold times.

● Maximizing Area Efficiency: Optimizing placement ensures that cells are positioned in such a way that the chip area is fully utilized while avoiding congestion and wasted space.

Detailed Explanation

Placement in VLSI design focuses on effectively positioning individual components within a predetermined floor plan. The primary objectives are:

1. Minimizing Delay: By arranging cells closer to their logical connections, we can ensure that signals are transmitted efficiently, decreasing the time it takes for a signal to travel from one cell to another. This is critical for high-speed operations.

2. Reducing Power Consumption: Longer interconnects can lead to increased power loss, so placing cells closer together can result in less power being consumed.

3. Meeting Timing Constraints: Ensuring that signals meet specific timing requirements is vital for the functionality of the chip. Proper placement helps maintain these timing requirements.

4. Maximizing Area Efficiency: Effective placement maximizes the use of available space on the chip, ensuring no area is wasted while avoiding congestion in specific sections, which can lead to complications in design.

Examples & Analogies

Think of placing different departments in a company building. For example, the marketing and sales departments should be close together as they frequently interact, much like minimizing delay between cells. If these departments are separated by long hallways (representing long interconnects), it slows down communication and can even lead to misunderstandings. Efficiently using the available office space while ensuring each team has what they need without overcrowding is similar to maximizing area efficiency in VLSI design.

Placement Techniques

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Placement can be divided into global placement and detailed placement.

● Global Placement: Global placement involves an initial placement of cells across the entire chip. The goal is to minimize the total wirelength by positioning cells near their logical neighbors. During global placement, the designer does not worry about exact cell locations but focuses on reducing congestion and improving timing performance.

● Detailed Placement: Detailed placement is the refinement of the global placement. It fine-tunes the positions of cells to meet detailed constraints such as timing, signal integrity, and manufacturability. It involves adjusting the locations of cells to reduce routing congestion and satisfy design rules.

Detailed Explanation

There are two main types of placement techniques used to position cells effectively:

1. Global Placement: This is the first step where an overall layout of the cells is created. The main aim is to reduce the total length of connections (wirelength) by placing nearby cells together, thus facilitating better communication between them without focusing on precise locations initially. This can be thought of as sketching out the basic layout of a building before getting into the details.

2. Detailed Placement: This step involves refining the initial layout made during global placement. Here, precise positions of the cells are adjusted to meet specific design requirements, ensuring that all cells function optimally within the defined space and under electrical characteristics such as signal integrity. It is like deciding the exact placement of furniture in a room based on functional use and accessibility after having determined the room layout.

Examples & Analogies

Think of planning a party at home. Initially, you decide which areas (rooms) to use for different activities. This is similar to global placement - a broad arrangement without worrying about exact furniture positioning. Once the areas are set, you then plan where each chair and table should go for optimal use, ensuring guests can move around easily and everything is accessible. This detailed planning mirrors the detailed placement step in VLSI design.

Placement Algorithms

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Simulated Annealing: A probabilistic algorithm inspired by the annealing process in metallurgy. It iteratively adjusts the placement of cells to minimize wirelength and optimize for performance while avoiding local minima.

● Force-Directed Algorithms: These algorithms model the placement process as a system of forces, where cells are pushed and pulled to their optimal positions based on attractive and repulsive forces. The force-directed method can minimize wirelength and reduce congestion.

● Greedy Algorithms: Greedy algorithms place cells based on local optimization criteria. These algorithms are typically faster but may not achieve the global optimal placement.

Detailed Explanation

Placement algorithms help place the components effectively and include:

1. Simulated Annealing: This method mimics a physical process where a metal cools and solidifies, allowing for adjustments to positions that minimize wirelength iteratively. The algorithm randomly explores placement possibilities while avoiding getting stuck in suboptimal configurations, similar to how a metal worker finds the right shape over time.

2. Force-Directed Algorithms: This model treats cells as particles that exert forces on one another. If two cells are too far apart, they attract each other, while cells that are too close repel each other. This pushes cells into optimal positions naturally, like arranging magnets in a way where they attract to form a stable pattern while avoiding clumping together.

3. Greedy Algorithms: Greedy methods focus on making the best local choice at each step without considering future implications. They can be effective and fast, but may miss out on achieving the best overall layout due to their lack of a broad view, much like a person making the best decision for immediate needs without planning for the long run.

Examples & Analogies

Consider organizing a car parking lot. Simulated annealing is like a process where you iteratively rearrange cars to find the best layout over time. A force-directed approach would be like having cars that attract or repel each other based on their type or size, ensuring they fit optimally in the space. Finally, a greedy algorithm would be parking the first car you see in the nearest available spot without thinking about how that might affect the rest of the parking.

Placement Tools

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Cadence Innovus: Innovus offers an automated solution for placement, focusing on timing, power, and area optimization. It integrates both global and detailed placement strategies for optimal results.

● Synopsys IC Compiler II: Offers advanced placement capabilities, including timing optimization and power-aware placement for large-scale SoC designs.

● OpenROAD: An open-source tool that automates placement while balancing timing and area constraints, commonly used in academic research and smaller designs.

Detailed Explanation

To automate and enhance the placement process, several tools are utilized by designers:

1. Cadence Innovus: This tool automates the placement process by focusing on key areas such as timing, power, and area. It provides solutions for both global and detailed placement, making it a powerful tool across different stages of design.

2. Synopsys IC Compiler II: This offers advanced features that allow for placement which takes into account the timing of signals and power efficiency, especially in complex designs requiring System on Chip (SoC) methodologies.

3. OpenROAD: An open-source alternative that automates much of the placement work while ensuring that necessary constraints related to timing and area are respected. Its accessibility makes it popular in educational settings and among smaller developers.

Examples & Analogies

Think of these tools as different professional organizers for a large event. Cadence Innovus is like an event planner who considers both the space and schedule, ensuring everything is in place on time. Synopsys IC Compiler II functions like a specialized coordinator who focuses on every little timing detail to ensure the schedule runs smoothly. Lastly, OpenROAD is like a volunteer organizer (open-source) who efficiently puts things in order while still learning and contributing to the overall organization effort.

Key Concepts

-

Placement: Arranging cells within a predefined floor plan.

-

Objectives of Placement: Goals include minimizing delay, reducing power, and maximizing area efficiency.

-

Global Placement: The step of arranging cells broadly to enhance placement later.

-

Detailed Placement: Fine-tuning placements to meet specific timing and signal criteria.

-

Placement Algorithms: Methods to optimize the arrangement of cells.

Examples & Applications

When arranging a network of computers in a data center, placing frequently communicating servers close to each other mirrors the principles of minimizing wirelength in VLSI placement.

Using simulated annealing in chip placement can be likened to finding the best route for delivery trucks; sometimes taking a longer route can lead to minimal traffic delays overall.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In placement design, don't be remiss, minimize delay and power; that's the bliss!

Stories

Imagine an architect designing a new campus layout: they place the library near the computer lab to minimize travel. Likewise, in VLSI design, we place cells to optimize interconnect lengths.

Memory Tools

Remember 'D-P-A' for placement goals – Delay, Power, and Area efficiency!

Acronyms

Use 'G-D' for Global and Detailed placement. G for the grand overview, D for detailed adjustment.

Flash Cards

Glossary

- Global Placement

The initial arrangement of cells across the entire chip to minimize total wirelength.

- Detailed Placement

A refinement stage that adjusts cell positions to comply with specific constraints like timing.

- Simulated Annealing

A probabilistic algorithm used to minimize wirelength and optimize performance during placement.

- ForceDirected Algorithms

Algorithms that model placement as a system of forces, utilizing attractive and repulsive dynamics to find optimal configurations.

- Greedy Algorithms

Algorithms that make the locally optimal choice at each stage with the hope of finding a global optimum.

Reference links

Supplementary resources to enhance your learning experience.