Ball Grid Array (BGA)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding BGA Structure

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into Ball Grid Array technology. Let's start with its structure. Instead of leads, BGA features a grid of solder balls. Can anyone guess what these balls do in the connection process?

Do the solder balls connect the IC to the PCB?

Exactly! These solder balls create the connection points. This brings us to the idea of reflow soldering, where the solder melts to form strong connections. Can anyone explain what reflow soldering involves?

Isn't that the process where the solder transitions from a solid to liquid state and then back again?

Correct! So remember, BGA's ball grid allows for better thermal management due to the larger surface area. Can someone tell me why that’s important?

Better heat dissipation helps prevent overheating, right?

Exactly! Let’s summarize the key points: BGA utilizes solder balls for connection and has efficient heat dissipation. Great job, everyone!

Advantages of BGA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've covered the structure, let’s talk about the advantages. Why do you think BGA is favored for high-performance devices?

It has a higher pin count in a smaller space, so it can fit more connections.

Absolutely right! This capability is crucial for power-hungry components. Can someone also mention another benefit regarding thermal performance?

It helps with heat management because more surface area dissipates heat better.

Exactly! These factors make BGA ideal for microprocessors and GPUs. Remember these key advantages: higher pin count and improved thermal performance. Who can summarize them?

So BGA has more connections in a compact area and manages heat better!

Perfect summary! Well done.

Disadvantages of BGA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift gears and look at BGA's disadvantages. What do you think might be a challenge with using BGA technology?

I heard that inspecting BGA can be difficult since you can’t see the solder joints easily.

That's correct! The invisibility of solder joints necessitates X-ray inspections. What about assembly challenges?

Is it because BGA requires precise alignment, making it complex and possibly expensive?

Exactly! So remember this: while BGA has significant advantages, it's also harder to inspect and comply with complex assembly requirements. Can anyone summarize these disadvantages?

BGA is hard to inspect and requires precise assembly techniques, which can be costly.

Great summary! Let’s keep this in mind as we move on to applications.

Applications of BGA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss where we can apply BGA technology. What sorts of devices utilize BGA?

High-performance processors, like CPUs and GPUs!

Correct! BGA is critical in devices where thermal management and compact design are necessary. Anyone think of an example beyond processors?

What about mobile devices, like smartphones?

Exactly! They're perfect examples due to their compact size and need for high performance. Now, why would networking equipment like routers also use BGA?

Since they need to process data quickly and reliably.

Great insights! So, let’s blend the applications: BGA is essential for processors, mobile devices, and networking equipment. Summarized?

BGA is used in processors, mobile devices, and networking equipment due to performance needs.

Well done! Understanding the applications gives us critical insight into choosing the right technology.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

BGA represents a modern modification in surface-mount technology, utilizing a grid of solder balls for secure connections. This design enhances thermal management and mechanical strength, favoring high-performance applications despite challenges in inspections and assembly complexity.

Detailed

Ball Grid Array (BGA)

The Ball Grid Array (BGA) is a type of surface-mount packaging that employs a grid of small solder balls as connection points between integrated circuits (ICs) and printed circuit boards (PCBs). This technology enhances performance aspects such as thermal management, electrical conductivity, and mechanical strength over traditional surface-mount packages.

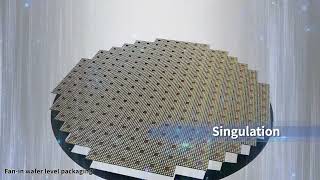

Structure of BGA Packaging

- Ball Grid: Instead of conventional leads or pads, BGA packages feature a grid of small solder balls at their base, which connect the IC to the PCB.

- Reflow Soldering: The solder balls are melted during reflow soldering to establish strong electrical connections.

Advantages of BGA

- Higher Pin Count: BGA can accommodate a greater number of connections (pins) in a compact area, making it suitable for high-performance devices, such as processors and graphical units.

- Improved Thermal Performance: A larger area in BGA packaging facilitates better heat dissipation, which is essential for handling high-power applications.

- Better Mechanical Strength: The design provides robust mechanical support, minimizing damage risks during handling and thermal cycling.

Disadvantages of BGA

- Inspection Difficulty: Solder joints are hidden under the package, complicating inspection and requiring advanced techniques like X-ray inspections.

- Complex Assembly: Precise alignment and specialized soldering techniques are pivotal, raising assembly costs.

Applications of BGA

- High-Performance Processors: Used intensively in microprocessors and GPUs.

- Mobile Devices: Ideal for compact devices like smartphones and tablets.

- Networking Equipment: Found in routers and data centers where processing speed is critical.

Understanding the structure, advantages, and applications of BGA packaging is crucial for selecting appropriate technology in electronic design.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of BGA Packaging

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The Ball Grid Array (BGA) is a type of surface-mount packaging that uses a grid of small solder balls as the connection method. BGA packages offer superior performance in terms of thermal management, electrical conductivity, and mechanical strength compared to traditional surface-mount packages.

Detailed Explanation

The BGA packaging technology is designed for improved performance in various electrical and mechanical aspects. Unlike other packaging types, it utilizes a grid layout of small solder balls, which enhances the electrical connection with the circuit board. This innovative design allows for better heat distribution and stronger mounting, making BGA a popular choice for high-performance integrated circuits.

Examples & Analogies

Think of the BGA like a network of tiny roads (solder balls) that connect a city (the IC) to the main highway (the PCB). The more roads you have, the more traffic can flow smoothly, which in this case means signals and power can travel quickly and efficiently.

Structure of BGA Packaging

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Ball Grid: Instead of leads or pads, BGA components have an array of small solder balls arranged in a grid pattern on the bottom of the package. These balls serve as the connection points for the IC to the PCB.

● Reflow Soldering: The BGA is soldered to the PCB using reflow soldering, where the solder balls melt and form a strong electrical connection between the IC and the PCB.

Detailed Explanation

BGA packaging features an array of small solder balls, which replace traditional leads for making connections with the PCB. During assembly, these balls are heated until they melt, allowing them to bond with the PCB surface, creating a reliable electrical connection. This method is called reflow soldering, and it is crucial for achieving a strong and durable solder joint.

Examples & Analogies

Imagine making a snowman. Instead of using sticks for arms (like traditional leads), you decide to use small balls of snow arranged in a neat pattern around the snowman (represented by the grid of solder balls). When you press them together, they stick firmly, creating stronger arms. This is similar to how the solder balls in BGA packaging create robust connections.

Advantages of BGA Packaging

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Higher Pin Count: BGA allows for a higher number of connections (pins) in a smaller space, making it ideal for high-performance ICs such as processors, memory, and GPUs.

● Improved Thermal Performance: The large area of the BGA package provides better heat dissipation compared to traditional packages, making it suitable for high-power, high-performance applications.

● Better Mechanical Strength: The solder balls in BGA provide better mechanical support, reducing the risk of damage during handling or thermal cycling.

Detailed Explanation

One of the key benefits of BGA is its ability to accommodate many more connection points in a compact design, which is essential for advanced ICs that require high data throughput. Additionally, the design enhances thermal performance—suitable for high-powered devices—by dispersing heat more effectively. The mechanical strength offered by the solder balls helps protect against physical stresses that could damage the connections.

Examples & Analogies

Consider a densely packed bookshelf. The more shelves (pins) you can fit into that bookshelf without making it too bulky (size), the more books (connections) you can store in a small area. BGAs achieve this efficiency with better heat management, similar to how a well-ventilated shelf can keep books fresher.

Disadvantages of BGA Packaging

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Inspection Difficulty: Unlike through-hole and some surface-mount packages, the solder joints in BGA packages are not visible, making inspection and rework more challenging. Special X-ray inspection techniques are often used.

● Complex Assembly: BGA packages require precise alignment and advanced soldering techniques, which can increase assembly complexity and cost.

Detailed Explanation

Despite their advantages, BGA packages have some drawbacks. The solder joints are difficult to inspect visually since they lie underneath the package, necessitating advanced techniques for quality control, such as X-ray inspections. Additionally, the assembly process demands high precision, which can drive up production costs and complexity.

Examples & Analogies

Think of BGA as a beautiful puzzle that you can't see the back of. While the finished picture (the functional IC) looks great, ensuring all pieces fit perfectly underneath can be challenging. You might need special tools (like X-ray views) to validate that every piece is in place without taking the puzzle apart.

Applications of BGA Packaging

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● High-Performance Processors: Used in microprocessors, graphics processing units (GPUs), and memory modules due to their high pin count and ability to handle high power dissipation.

● Mobile Devices: Widely used in smartphones, tablets, and other compact devices where performance and size are critical.

● Networking Equipment: Commonly found in routers, switches, and data center equipment where high-speed processing and reliability are required.

Detailed Explanation

Due to its high pin count and thermal performance capabilities, BGA packaging is often used in applications such as microprocessors and GPUs, which require efficient processing power. It is also prevalent in mobile devices where space and performance are crucial. This packaging type is common in networking equipment, supporting the demands for high-speed data processing and connectivity.

Examples & Analogies

Imagine a busy train station: the BGA is like a platform designed for many trains (high-performance processors) to dock simultaneously. It needs to handle high traffic (power dissipation) efficiently while maintaining smooth operations, similar to how mobile devices and networking equipment work in the tech world.

Key Concepts

-

BGA Structure: Composed of solder balls providing connection points.

-

Thermal Performance: Enhanced thermal dissipation due to larger mounting area.

-

Mechanical Strength: Better durability against handling stresses.

-

Application Scope: Used in high-performance computing and compact mobile devices.

Examples & Applications

Microprocessors and GPUs are commonly packaged in BGA due to their need for high pin count and thermal management.

Smartphones utilize BGA packaging for their compact size and performance requirements.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

With balls in a grid, connections are made, helping devices not to overtrade.

Stories

Imagine a small city (the PCB) where each house (IC) is connected by vibrant balloons (solder balls), making all streets (connections) easily accessible while ensuring the community (device) never overheats!

Memory Tools

Remember BGA's benefits with 'HAP': Higher pin count, Awesome thermal management, Perfect in assembly strength.

Acronyms

BGA stands for Bodyguards of Gear Assemblies (due to their protection and support in tight spaces).

Flash Cards

Glossary

- Ball Grid Array (BGA)

A type of surface-mount packaging utilizing a grid of solder balls for electrical connections.

- Reflow Soldering

A soldering technique where solder balls are melted to create connections between ICs and PCBs.

- Thermal Management

Techniques used to control the temperature of electronic components, preventing overheating.

- Mechanical Strength

The ability of a package to maintain structural integrity under physical stress.

Reference links

Supplementary resources to enhance your learning experience.