Surface-Mount Technology (SMT)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to SMT

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing Surface-Mount Technology or SMT. Can anyone tell me what they think SMT is?

Is it a method for placing components on PCBs without drilling holes?

Exactly! SMT allows us to directly attach components to the surface of printed circuit boards, which helps us design smaller and more compact electronics.

So, does that mean there are advantages to using SMT over other methods?

Great question! Yes, SMT has several advantages, such as higher component density, cost-effectiveness for mass production, and suitability for automation. Does anyone know why component density is important?

Because it allows for more features in a smaller device!

That's it! A higher density of components means more features can be integrated into a device without increasing its size.

Advantages of SMT

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's delve deeper into the advantages of SMT. What do you think makes SMT more cost-effective than other assembly methods?

Maybe because it reduces the labor needed for assembly?

Exactly! The automation in SMT assembly processes significantly reduces labor costs and error rates. Can anyone add to that?

I think shorter interconnections also help with performance, right?

Correct! These shorter connections can lead to faster signal transmission and reduced signal loss.

What about the size of SMT components?

Good point! SMT components are typically smaller, which is key in minimizing the overall size of the devices.

Disadvantages and Challenges of SMT

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

While SMT has many advantages, it also has some disadvantages. Who can name one?

Lower mechanical strength compared to through-hole components?

Exactly! SMT components aren't as robust, which can be an issue in applications with significant mechanical stress, like in heavy machinery. What about repairs?

Is it harder to repair SMT components?

Yes! The complexity of SMT can indeed make repairs and replacements more challenging, especially for fine-pitch components. Why do you think this matters in real-world applications?

Because it could lead to higher costs in maintenance?

That's correct! The difficulty in repairs can increase overall maintenance costs for devices.

Applications of SMT

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the strengths and weaknesses of SMT, let’s look at where it’s commonly applied. Where do you think we see SMT used the most?

Probably in consumer electronics like smartphones?

Absolutely! Smartphones, laptops, and home appliances are primary examples. What about other fields?

Maybe in automotive electronics?

Yes, automotive electronics and medical devices as well! High-density boards are crucial for their compact designs.

So, SMT is really important across various industries?

Exactly! SMT is critical in modern electronics, allowing for the innovation of compact devices packed with advanced features.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

SMT has become the standard in electronic manufacturing due to its efficiency in utilizing space on PCBs, allowing for a greater density of components compared to traditional methods. This section discusses the structure, advantages, disadvantages, and applications of SMT in modern electronics, highlighting its pivotal role in industries like consumer electronics and automotive.

Detailed

Surface-Mount Technology (SMT)

Surface-Mount Technology (SMT) has revolutionized the way electronic components are assembled onto printed circuit boards (PCBs). Unlike traditional methods that require drilled holes for component leads, SMT allows components to be directly mounted on the surface of the PCB. This structural difference leads to a number of significant advantages:

Key Features of SMT

- Flat Leads: Components have small leads or pads, attached directly to the PCB's surface.

- No Holes Required: The absence of holes enables a high-density layout, reducing the overall size of PCBs.

Advantages of SMT

- Higher Component Density: This innovation supports smaller and lightweight devices packed with features.

- Automation: SMT is highly suitable for automated assembly processes, cutting down labor costs and enhancing soldering precision.

- Improved Performance: The shorter electrical paths within SMT can lead to faster signal transmission and less signal degradation.

- Cost-Effective: Particularly advantageous for mass production where speed and efficiency are critical.

Disadvantages of SMT

- Mechanical Strength: SMT components may be less robust against physical stress and vibration compared to through-hole alternatives.

- Repair and Rework Challenges: The complexity of SMT can make repairs and replacements more difficult, especially on mult-layer or fine pitch boards.

Applications of SMT

SMT is ubiquitous in various electronic applications, particularly in consumer electronics such as smartphones, laptops, and home appliances. It is also commonly employed in high-density boards for automotive electronics and medical devices.

Understanding SMT is vital for anyone involved in the electronics field, as it is crucial in designing efficient and compact electronic systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Surface-Mount Technology (SMT)

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

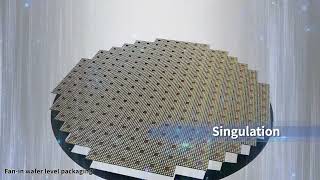

Surface-mount technology (SMT) has become the standard for mounting components on PCBs. In SMT, the components are placed directly on the surface of the PCB, with electrical connections made through solder pads on the surface of the board. The components do not require drilled holes in the PCB, making SMT an efficient method for high-density, automated manufacturing.

Detailed Explanation

Surface-Mount Technology (SMT) is a method used to attach electronic components onto circuit boards (PCBs). Unlike traditional methods, SMT components are placed directly on the board instead of being inserted into holes. This allows for a more compact arrangement of components, which is especially beneficial in industries where space is limited. The absence of drilled holes simplifies the manufacturing process and promotes efficiency, particularly in automated assembly lines.

Examples & Analogies

Think of SMT like packing items in a small suitcase without any dividers compared to a regular suitcase with sections for each item. When you pack in a small suitcase, you can squeeze more items together without gaps, just like SMT allows for more components on a circuit board without needing space for holes.

Structure of Surface-Mount Packaging

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Flat Leads: SMT components have small leads or pads that are directly soldered to the surface of the PCB.

● No Holes Required: Unlike through-hole components, SMT components do not require holes in the PCB, which results in a higher-density layout and reduced PCB size.

Detailed Explanation

SMT components use flat leads or pads that are soldered directly onto the PCB's surface. This differs from through-hole components that need holes to insert their leads. The elimination of holes means that the board can be designed in a more compact and efficient manner, allowing more components to fit into a smaller space.

Examples & Analogies

Imagine a classroom designed for desks with legroom (like a through-hole design) versus desks that sit closely together without gaps (like SMT). The second design can fit more students in the same space, similar to how SMT allows more components on a PCB.

Advantages of Surface-Mount Technology

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Higher Component Density: SMT allows for a denser arrangement of components on the PCB, resulting in smaller, lighter devices with more features.

● Automation: SMT is ideal for automated assembly, reducing labor costs and improving the consistency of the soldering process.

● Improved Performance: SMT components are typically smaller and have shorter interconnection lengths, which can result in faster signal transmission and reduced signal loss.

● Cost-Effective: SMT is more cost-effective for mass production due to its suitability for high-speed, automated manufacturing.

Detailed Explanation

SMT offers several benefits including higher component density, leading to more features in smaller devices. Automation allows for quicker assembly, thus lowering production costs and creating uniform quality in solder joints. Additionally, because SMT components are smaller and the connection paths are shorter, they can transmit signals faster and experience less loss, making them more efficient for electronic devices.

Examples & Analogies

Think of SMT like a well-organized spice rack in a kitchen. A compact spice rack allows you to see and access all the spices quickly (higher density), and using labeled jars (automation) means anyone can use it easily without extra help. The efficiency helps you cook faster with less mess (improved performance).

Disadvantages of Surface-Mount Technology

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Mechanical Strength: SMT components are not as mechanically robust as through-hole components and may not be suitable for applications with significant mechanical stress or vibration.

● Repair and Rework: SMT components can be more difficult to repair or replace, especially in the case of complex multi-layer boards or fine-pitch components.

Detailed Explanation

Despite its advantages, SMT has drawbacks. The components may lack mechanical strength compared to through-hole components, making them less suitable for environments with heavy vibrations or stress. Additionally, if an SMT component fails, it can be harder to repair or replace due to their small size and the intricate nature of modern circuit designs.

Examples & Analogies

Think of SMT components like delicate figurines that look beautiful but are fragile. If one breaks, it's much trickier to fix than a sturdy statue made of metal (through-hole component), which can withstand a lot of bumps and knocks before breaking.

Applications of Surface-Mount Technology

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Consumer Electronics: Widely used in consumer electronics such as smartphones, laptops, and home appliances.

● High-Density Boards: Ideal for applications requiring compact designs with a high component density, such as automotive electronics, medical devices, and network equipment.

Detailed Explanation

SMT is commonly used in consumer electronics, which require compact designs and higher functionality within limited space. This technology is favored in devices like smartphones, laptops, and various household appliances while also being essential in automotive, medical, and network equipment, where space and performance are critical considerations.

Examples & Analogies

Picture the inside of a smartphone, which is crammed with all sorts of technology into a tiny case. SMT allows manufacturers to pack a lot of features into that small space, much like a magician who can fit large props into a small box, leaving the audience amazed at how he makes it all work in such a compact setting.

Key Concepts

-

Components are mounted directly on PCB surface in SMT.

-

Higher density designs allow more features in smaller devices.

-

Automation reduces labor costs and enhances soldering quality.

-

Though SMT has benefits, it poses challenges for mechanical strength and repair.

Examples & Applications

Example: Smartphones and tablets utilize SMT to achieve compact designs with many features.

Example: Automotive electronics rely on SMT for small forms and efficient performance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To mount without a hole, is UTC, SMT fills the role.

Stories

Imagine a tiny electronic army assembling itself on a battlefield called PCB, all standing shoulder to shoulder, ready to create powerful gadgets.

Memory Tools

CAPS: Compact, Automation, Performance, Strength - key concepts of SMT.

Acronyms

SMT

Surface-Mount Technology - Surface

Mount

Tight Design.

Flash Cards

Glossary

- SurfaceMount Technology (SMT)

A technology for mounting electronic components directly onto the surface of PCBs without drilled holes.

- Printed Circuit Board (PCB)

A board used for mechanically supporting and electrically connecting electronic components.

- Component Density

The number of components that can be placed on a given area of a PCB.

- CostEffectiveness

The efficiency of a business process in terms of the monetary costs incurred relative to the benefits gained.

- Automation

The use of technology to perform tasks with minimal human intervention.

- Mechanical Strength

The ability of a material or component to withstand mechanical forces without deformation or failure.

Reference links

Supplementary resources to enhance your learning experience.