Structure of Through-Hole Packaging

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Component Leads

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with the primary component of through-hole packaging: the component leads. These are the long pins that extend through holes in the PCB. Why do you think these leads are important?

They must connect the component to the circuit, right?

Exactly! The leads ensure a solid electrical connection. When soldered, they create a secure bond that can handle high physical stress.

Do these leads impact the circuit's performance?

Yes, good observation! The length and thickness of the leads can affect how well electricity flows through them. This is especially crucial in high-power applications.

Can they be replaced easily if they are damaged?

They can! The design of through-hole packaging allows for easier repairs since the leads can be accessed and soldered more conveniently.

So, if one lead fails, we can just replace it without changing the whole component?

Absolutely! This is one of the key advantages of through-hole technology, especially in systems that are subject to wear and tear.

In summary, component leads are vital for creating and maintaining electrical connections, providing an ease of repair and durability.

PCB Holes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s explore the PCB holes. These holes play a significant role in through-hole packaging. Why do you think they have to be aligned with the component leads?

It’s probably to make sure the connections are correct!

Correct! Proper alignment is essential; if they aren't aligned, soldering won't create an adequate connection. What's the difference between plated and unplated holes?

Plated holes have metal that helps conduct electricity.

Exactly! Plated holes connect different layers of the PCB electrically, enhancing functionality, while unplated holes are for physical support only.

So, in high-frequency circuits, why wouldn’t we just use unplated holes?

Good question! In high-frequency designs, the integrity and speed of the connections are critical. Plated holes can reduce resistance and signal loss, making them preferable.

Are unplated holes used in any specific applications?

Yes! They're often used for physical stability and less critical connections, like for mechanical support or mounting hardware.

In summary, PCB holes are crucial for component integration, electrical connectivity, and mechanical stability. Their type and alignment with leads greatly affect the overall performance of the circuit.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Through-hole packaging involves components with long leads that pass through PCB holes, either plated or unplated. This section explains key elements of the structure, including component leads and PCB holes, discussing their importance in establishing mechanical and electrical connections.

Detailed

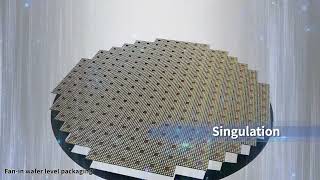

Structure of Through-Hole Packaging

Through-hole technology (THT) is one of the foundational methods for mounting electronic components on printed circuit boards (PCBs). In this section, we identify the key structures that form the backbone of through-hole packaging, emphasizing two critical aspects: - Component Leads: These are the long pins that penetrate through the PCB, connecting electrical components to the circuit. The soldering of these leads on the opposite side of the board is essential for creating stable electrical connections. - PCB Holes: The alignment of these holes with the component leads is crucial. They can be either plated, providing conductive paths between PCB layers, or unplated, facilitating mechanical support and assembly. Understanding these elements is vital as they contribute to the durability and functionality of electronic packages, setting the foundation for applications in diverse fields such as power electronics, prototypes, and military standards.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Component Leads

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Through-hole components have long leads or pins that pass through the PCB and are soldered to pads on the opposite side of the board.

Detailed Explanation

Through-hole components come with long metal pins called leads. These leads are designed to be inserted through holes that are drilled into a printed circuit board (PCB). After insertion, the leads extend through the board and are soldered to pads on the opposite side to create a secure connection. This design allows for a strong electrical connection between the component and the PCB.

Examples & Analogies

Think of the component leads like the legs of a chair. Just as chair legs need to be firmly attached to the floor to provide stability, the leads need to be securely soldered to the PCB for the electronic components to function properly.

PCB Holes

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The PCB has holes that align with the leads of the components. These holes are either plated or unplated, with plated holes providing a conductive path between layers of the PCB.

Detailed Explanation

The holes in the PCB serve as the passageways for the component leads. These holes can either be plated or unplated. Plated holes have a thin layer of conductive material that lines the inside, allowing electrical signals to travel between different layers of the PCB, effectively connecting various components. Unplated holes do not offer this conductive feature and are used for mechanical support only.

Examples & Analogies

Imagine the holes in the PCB as tunnels in a city. Plated holes are like tunnels that have electrical wiring running through them, allowing energy to flow between different parts of a city. Unplated holes, on the other hand, are like regular tunnels as a form of support, helping keep the city organized but not having any wires running through them.

Key Concepts

-

Component Leads: Essential for making electrical connections between components and the PCB.

-

PCB Holes: Critical for stability and connectivity; can be either plated or unplated based on application.

Examples & Applications

Power supplies often use through-hole packaging due to the need for durable connections under high stress.

Prototyping boards frequently use through-hole technology as they facilitate easy component replacement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Leads so long, they go through, to connect the circuit, that's what they do!

Stories

Once in a busy electronics factory, there lived a pair of component leads who always went to the hole in the PCB. That's how they made friends with the circuit and worked together!

Memory Tools

PULL (Plated for Uniform Layers, Unplated for Light Load) to remember the uses of each type of PCB hole.

Acronyms

CAP (Component, Attach, Power) reminds us of the roles of leads in through-hole packaging.

Flash Cards

Glossary

- ThroughHole Packaging

A method of mounting electronic components where leads pass through PCB holes and are soldered on the opposite side.

- Component Leads

Long pins of through-hole components that pass through the PCB to create electrical connections.

- PCB Holes

Holes in printed circuit boards that align with component leads; can be plated or unplated.

Reference links

Supplementary resources to enhance your learning experience.