Artificial Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Artificial Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we are discussing artificial aggregates. These are aggregates produced via industrial processes rather than naturally sourced. What kinds of materials do you think might fall into this category?

Could it include things like recycled bricks or materials from industrial waste?

Absolutely! Crushed bricks and slag from steel production are two prime examples. They help in both construction and sustainability efforts.

What makes them suited for road construction?

Great question! They are economical and can utilize waste materials, making them an environmentally friendly choice.

Are there any limitations associated with using them?

Yes, while they have advantages, their performance can vary based on how they're produced, which is crucial to assess.

To summarize, artificial aggregates are an important resource that can provide both economic and environmental benefits.

Applications of Artificial Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to applications. Where do you believe artificial aggregates are typically used in road construction?

I think they might be used in low-traffic areas or secondary roads?

Exactly! They are often used in low-traffic roads and secondary pavements. This is a strategic application because it allows for resource optimization.

Are they used in any other areas besides roads?

Good inquiry! While primarily in roads, they're increasingly being examined for use in other constructions like sidewalks and foundations.

In summary, artificial aggregates are versatile materials primarily used in low-traffic roads, helping to support sustainable practices.

Evaluating Artificial Aggregate Properties

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand their applications, why is it crucial to evaluate the performance characteristics of artificial aggregates?

To make sure they can withstand loads and last over time?

Spot on! Evaluating strength, durability, and environmental impact helps ensure they will perform effectively in the field.

What specific tests do we conduct on these aggregates?

Great question! We often look at their strength, soundness, and other mechanical properties using standardized tests.

In summary, thorough evaluations are vital to confirm that artificial aggregates meet necessary specifications for road construction.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explains artificial aggregates, their definitions, examples, advantages, limitations, and typical applications, focusing on their importance in sustainable construction and low-traffic road projects.

Detailed

Artificial Aggregates

Artificial aggregates, as defined in this section, are materials produced through industrial processes or modified from natural sources to meet specific construction requirements. They include crushed bricks, slag from steel industries, and fly ash aggregates. These materials are generally applied in low-traffic roads and secondary pavements.

Key Points:

- Definition: Artificial aggregates are synthesized rather than sourced from the natural environment.

- Examples: Common examples encompass crushed bricks, steel slag aggregates, and fly ash aggregates, illustrating their diversity.

- Applications: Primarily employed in low-traffic roads and for constructing secondary pavements, emphasizing their utility in sustainable practices.

- Advantages: They offer economical solutions, especially when utilizing industrial by-products.

- Limitations: Their performance may vary based on manufacturing processes and contamination factors, necessitating careful evaluation in design.

Understanding artificial aggregates enhances road construction designs while promoting sustainability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Artificial Aggregates

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Artificial aggregates are defined as aggregates produced by industrial processes or modified from natural sources.

Detailed Explanation

Artificial aggregates refer to materials created through industrial processes or by altering existing natural materials. Instead of being sourced directly from the environment, they are manufactured through specific techniques aimed at enhancing their properties.

Examples & Analogies

Think of artificial aggregates like synthetic materials used in sports. Just as synthetic fibers (like polyester) are made to improve performance in sportswear, artificial aggregates are designed to meet specific engineering needs in road construction, providing effective alternatives to natural materials.

Examples of Artificial Aggregates

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

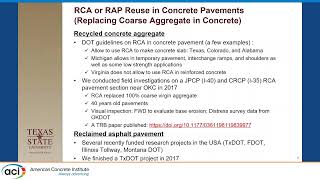

Examples of artificial aggregates include crushed bricks, slag aggregates (from steel industries), and fly ash aggregates.

Detailed Explanation

Several materials fall under the category of artificial aggregates. Crushed bricks are made from broken bricks, often from construction debris. Slag aggregates come from the by-products of the steel industry, while fly ash aggregates are produced from the residuals of coal combustion in power plants. These materials are processed to obtain specific sizes and qualities suitable for construction.

Examples & Analogies

Imagine a chef who makes a dish using leftover ingredients. Similarly, when bricks are crushed or slag is processed, it’s like taking what would be waste and turning it into something useful for building roads. This not only provides material but also helps manage waste.

Applications of Artificial Aggregates

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Artificial aggregates are primarily used for low-traffic roads and secondary pavements.

Detailed Explanation

Artificial aggregates are best suited for projects where traffic loads are lighter. They are often used in construction for low-traffic or secondary road applications where the highest performance materials are not necessarily needed. Their properties can vary based on the manufacturing process but still provide adequate functionality for these types of roads.

Examples & Analogies

Think of it this way: when building a family home, you may not need high-end materials like marble for every surface; instead, you might choose more economical options for less visible areas, just as artificial aggregates are chosen for roads that see less traffic.

Key Concepts

-

Artificial Aggregates: These are aggregates formed through industrial processes or modifications of natural materials.

-

Economic Value: Utilizing industrial by-products helps reduce costs and increase sustainability in construction.

-

Performance Evaluation: It is critical to assess the strength and durability of artificial aggregates to ensure they meet construction standards.

Examples & Applications

Crushed bricks are a common form of artificial aggregate used in low-traffic roads.

Steel slag aggregates offer competitive strength comparable to traditional aggregates, facilitating their use in various applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Artificial aggregates, from industry made, are not just waste, but a construction aid.

Stories

Imagine a construction crew, using crushed bricks from old homes, giving new life to what was waste, building roads with a sustainable base.

Memory Tools

Remember the acronym 'ABS': Artificial, Beneficial, Sustainable for artificial aggregates.

Acronyms

Acronym 'CRAFT'

Crushed bricks

Recycled Slag

Artificial materials making Future-friendly pavements.

Flash Cards

Glossary

- Artificial Aggregates

Aggregates produced through industrial processes or modifications from natural sources.

- Crushed Bricks

Aggregates created by crushing waste bricks, often used in low-traffic applications.

- Slag Aggregates

Materials produced from steel manufacturing processes, utilized for their strength and durability.

- Fly Ash Aggregates

Aggregates created using fly ash, a byproduct of coal combustion in power plants.

Reference links

Supplementary resources to enhance your learning experience.