Coarse Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Coarse Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to learn about coarse aggregates. Who can tell me what they are?

Are they the large stones used in concrete?

Yes, exactly! Coarse aggregates are materials that are retained on a 4.75 mm sieve. Can anyone guess why these materials are important?

I think they help make the pavement stronger?

Absolutely! They provide strength, stability, and durability to pavements. Remember this: 'Strength through Size.'

What are the common sizes of coarse aggregates?

Great question! Common sizes are 10 mm, 20 mm, and 40 mm. Knowing the sizes helps in selecting the right aggregates for specific uses.

So, it's crucial to choose the right size for the pavement design?

Exactly! It impacts the performance of the pavement greatly. Let's summarize: coarse aggregates are essential for strength and come in various sizes.

Applications of Coarse Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know what coarse aggregates are, let's discuss their applications. Where do we typically use these?

I think they're used in the base layers of roads?

Correct! Coarse aggregates are primarily used in base courses, bituminous concrete, and cement concrete pavements. Why do you think they are chosen for these applications?

Because of their strength and ability to handle traffic loads?

Absolutely! They can withstand heavy traffic loads and environmental stress. Here's a mnemonic: 'Coarse Constructs Confidence!'

Can they affect how durable the pavement is?

Yes! The right aggregates can enhance durability and reduce maintenance needs over time. Summing it up, coarse aggregates are integral in various pavement types due to their strength and stability.

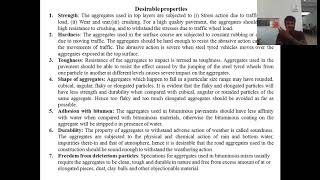

Characteristics of Coarse Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into the characteristics of coarse aggregates. What physical properties do you think are important?

Maybe hardness and shape?

Exactly! Hardness ensures strength and resistance to wear, while the shape affects how well the aggregates interlock. Let’s remember: 'Shape & Strength are Key!'

What shapes are best for interlocking in pavements?

Angular aggregates are preferred as they offer better interlocking compared to rounded ones. Why do you think that is?

Because they fit together closely?

Exactly! Proper interlocking minimizes voids and maximizes strength. In summary, the characteristics of coarse aggregates greatly influence their performance in pavement design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores coarse aggregates, defined as aggregate materials retained on a 4.75 mm sieve. It highlights their classifications, common sizes, and applications in road construction, emphasizing their impact on pavement quality and stability.

Detailed

Coarse Aggregates

Coarse aggregates represent a vital aspect of road construction. Defined as aggregates retained on a 4.75 mm sieve, they are essential for constructing various pavement types, including base courses and cement concrete pavements. Common sizes include 10 mm, 20 mm, and 40 mm aggregates. The selection of coarse aggregate size is influenced by the intended use and desired properties of the pavement, such as load-bearing capacity and resistance to environmental conditions. Understanding the characteristics and specifications of coarse aggregates helps ensure optimal performance and durability in road infrastructure.

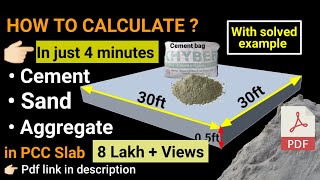

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition and Size

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Coarse Aggregates

- Size: Retained on 4.75 mm sieve

Detailed Explanation

Coarse aggregates are materials commonly used in road construction. They are defined by their size, specifically the ones that are too large to pass through a 4.75 mm sieve. This means when you try to sift them through a mesh screen that has holes measuring 4.75 mm, the larger pieces will remain on top. Essentially, if you were to explore the physical characteristics of these aggregates, you'd find that they are typically stones or gravel pieces.

Examples & Analogies

Think about sorting a collection of marbles. If you had a mesh with very fine holes, small marbles would fall through, while larger ones would sit on top. The same principle applies to coarse aggregates—we're identifying which materials are too big to pass through a specific size sieve.

Uses of Coarse Aggregates

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

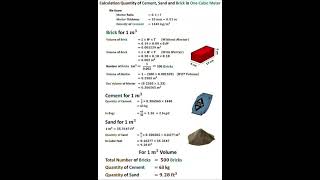

Chapter Content

Use: Base course, bituminous concrete, cement concrete pavements

Detailed Explanation

Coarse aggregates are essential components in various pavement structures. They are primarily used in the base course of roads, meaning they form the foundational layer that provides support. Additionally, they play a critical role in producing bituminous concrete and cement concrete pavements. This makes them important for ensuring the durability and stability of roads under heavy traffic.

Examples & Analogies

Imagine building a sturdy foundation for a house. Just like concrete is poured to create a strong base for your home, coarse aggregates in road construction help create a strong base for roads, supporting the weight of vehicles and ensuring the surface remains intact over time.

Common Sizes of Coarse Aggregates

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Common Sizes: 10 mm, 20 mm, 40 mm

Detailed Explanation

Coarse aggregates come in various sizes, typically categorized as 10 mm, 20 mm, and 40 mm. These sizes indicate the nominal maximum particle size of the aggregates, which will affect their performance in mixes. For example, smaller-sized aggregates (like 10 mm) may provide better compaction and workability in the mix than larger ones (like 40 mm). Choosing the correct size is critical for achieving optimal pavement properties.

Examples & Analogies

Think of different types of gravel used for driveways. Smaller gravel (10 mm) would be easier to work with when creating a smooth surface, while larger gravel (40 mm) can provide strength, but may need to be compacted differently. Just like choosing the right gravel size impacts a driveway, it can also affect how well a road performs.

Key Concepts

-

Coarse Aggregates: Aggregates larger than 4.75 mm, used in road pavements.

-

Applications: Used in base courses, bituminous concrete, and cement concrete.

-

Characteristics: Important factors include hardness, shape, and interlocking for strength.

Examples & Applications

10 mm aggregates are commonly used for residential pavements.

20 mm aggregates are often chosen for heavy-duty roads due to their load-bearing capacity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Coarse aggregates, strong and bold, on 4.75 mm they're controlled.

Stories

Imagine a construction site where engineers select the perfect coarse aggregates. They find angular stones fitting perfectly together like puzzle pieces, ensuring a strong pavement that can last against heavy traffic.

Memory Tools

CATS - Coarse Aggregates are Tough and Strong.

Acronyms

SACS - Sizes and Characteristics of Aggregates in Construction.

Flash Cards

Glossary

- Coarse Aggregates

Aggregates retained on a 4.75 mm sieve that are used in various layers of road construction.

- Retained

When aggregates are kept on a sieve without passing through it.

- Interlocking

The ability of aggregate particles to fit together tightly, enhancing stability.

- Durability

The ability of materials to withstand wear, pressure, or damage.

Reference links

Supplementary resources to enhance your learning experience.