Durability and Soundness

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the concept of durability in road aggregates. Can anyone tell me what durability means in this context?

I think durability is about how long something lasts, right?

That's correct! Durability here refers to how aggregates can resist weathering. For instance, how they handle freeze-thaw cycles. Why do you think this is important for pavements?

If the aggregate isn't durable, the pavement could break apart, especially with weather changes.

Exactly! And poor durability can lead to significant damage over time. Now, let’s dive into the testing methods used to evaluate durability.

Testing for Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

One way we assess durability is through the Sodium Sulfate/Magnesium Sulfate Soundness Test. Can anyone describe what we measure in this test?

We measure the weight loss of the aggregates after they undergo these cycles, right?

Correct, Student_3! We aim for specific loss percentages: no more than 12% for sodium sulfate and 18% for magnesium sulfate. Let's think about why these thresholds matter.

If the loss exceeds those limits, it means the aggregate isn't suitable for strong pavement?

Yes! It indicates that the aggregate may fail under environmental conditions, leading to pavement issues.

Importance of Soundness

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's now focus on what soundness means specifically. Who can recall the different facets of soundness?

Isn't it about how well the aggregate holds up against weathering?

Yes! Soundness assesses how aggregates handle chemical and physical weathering. Can anyone think of a scenario where poor soundness could lead to problems?

If it rains a lot and the temperature changes frequently, the aggregate might break down, leading to road damage.

Exactly, Student_2! This not only affects the pavement’s lifespan but also road safety.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section highlights the significance of durability and soundness in road aggregates, discussing key definitions, testing methods, and specifications that ensure aggregates can withstand weathering, especially freeze-thaw and wetting-drying cycles that may affect pavement stability.

Detailed

Durability and Soundness

Definition

Durability refers to the ability of road aggregates to resist weathering, particularly impacts from freeze-thaw and wetting-drying cycles. Soundness is a critical aspect of durability, focusing on the loss of weight in aggregates during specific tests.

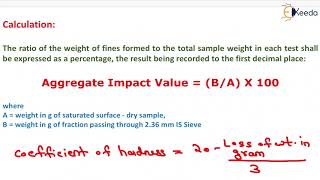

Tests Conducted

The primary test for evaluating the soundness of road aggregates is the Sodium Sulfate/Magnesium Sulfate Soundness Test.

Specifications

- Sodium Sulfate: A loss in weight exceeding 12% indicates poor soundness.

- Magnesium Sulfate: A loss in weight exceeding 18% suggests insufficient durability.

Understanding these parameters is vital for ensuring long-lasting and reliable pavement performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Durability and Soundness

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Resistance to weathering, especially under freeze-thaw and wetting-drying cycles.

Detailed Explanation

Durability and soundness refer to the ability of aggregates to withstand various environmental conditions without degrading. Specifically, durability means how well aggregates resist the damaging effects of freeze-thaw cycles (where water freezes and expands, then thaws) and wetting-drying cycles (where water enters the material and then evaporates, potentially causing damage). Both of these cycles can lead to cracks and breakdowns in materials that weaken their structural integrity over time.

Examples & Analogies

Think of a sponge left outside in the rain and then exposed to freezing temperatures. It absorbs water, and when the temperature drops, the water inside freezes and expands, causing the sponge to tear. Similarly, if road aggregates can't withstand these cycles, they can break down and lead to unsafe road conditions.

Testing Durability and Soundness

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Test: Sodium Sulfate/Magnesium Sulfate Soundness Test.

Detailed Explanation

To evaluate how durable an aggregate is, we perform specific tests, one of which is the Sodium Sulfate/Magnesium Sulfate Soundness Test. This test simulates the effects of weathering by exposing the aggregates to these sulfate solutions. After subjecting the aggregates to a certain number of cycles, any weight loss is measured. This weight loss indicates how well the aggregates can resist weathering forces. If they lose too much weight, they are deemed unsuitable for use in construction.

Examples & Analogies

Imagine dipping a dry sponge into saltwater, letting it dry, then repeating the process multiple times. Over time, the sponge begins to degrade because of the salt’s effects. The soundness test does something similar with aggregates, ensuring they can withstand environmental stressors without degrading.

Soundness Value Specifications

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Soundness Value: Loss in weight should not exceed 12% for sodium sulfate and 18% for magnesium sulfate.

Detailed Explanation

The soundness value specifies how much weight an aggregate can lose during the soundness test before it is considered unacceptable. For instance, an aggregate losing more than 12% of its weight when tested with sodium sulfate or more than 18% with magnesium sulfate indicates that it is not resilient enough to withstand weathering effects during its lifespan on the road. These specifications help ensure that road materials will stay intact and safe for use.

Examples & Analogies

Imagine you have a cookie that can crumble if left in the air for too long. If your cookie breaks apart and loses too much of its weight, you wouldn't want to serve it at a party. Similarly, engineers use the soundness value to ensure the 'cookie' (the aggregate) is strong enough to handle the environment it will face on the roads.

Key Concepts

-

Durability: The resistance of aggregates to weathering effects.

-

Soundness: The measure of how aggregates maintain integrity during weathering.

-

Testing: Includes Sodium Sulfate and Magnesium Sulfate tests.

Examples & Applications

When aggregates used in road construction are tested for soundness, a weight loss under 12% for sodium sulfate signifies good durability.

In regions with severe weather conditions, using aggregates with high soundness values is crucial to avoid pavement failures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Durability is our goal, weather's toll can't take control.

Stories

Once there was a road, built with care, but the aggregates lost their soundness in the winter air. After freeze-thaw, the pavement broke, a reminder that soundness, not just looks, is no joke.

Memory Tools

Remember the word 'DURABLE' for durability—Determine Under Roads And Be Loudly Enduring.

Acronyms

S.L.A.M - Soundness, Loss, Aggregate, Measure.

Flash Cards

Glossary

- Durability

The ability of aggregates to resist degradation under environmental influences like weathering.

- Soundness

The capacity of aggregates to maintain their integrity during weathering cycles, evaluated through weight loss in tests.

- FreezeThaw Cycle

The process where water trapped in aggregate expands upon freezing, potentially causing fractures.

- Testing

Evaluative processes used to assess the properties and performance of materials.

Reference links

Supplementary resources to enhance your learning experience.