Soundness Test

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Soundness Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about the Soundness Test. Can anyone explain what we mean by 'soundness' when it comes to aggregates?

I think it refers to how durable the aggregates are under different weather conditions.

Exactly! Soundness relates to an aggregate's ability to withstand weathering processes, especially freeze-thaw cycles. Why do you think this is important for road construction?

If the aggregates break down quickly, the road will fail sooner.

Right! So, to evaluate this soundness, we perform a test using sodium sulfate and magnesium sulfate. What do you think happens to aggregates in these tests?

They probably get soaked and we measure how much weight they lose.

Correct! The acceptable weight loss limits are a maximum of 12% for sodium sulfate and 18% for magnesium sulfate, indicating good durability.

Understanding the Testing Process

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand why the Soundness Test is important, let’s go over how it’s done. Can someone describe the first step in the process?

We start by preparing the aggregate sample, right?

Correct! Once we have our aggregate samples, they are submerged in sodium sulfate or magnesium sulfate solutions. What do you think we do next?

We wait and then measure the weight loss after a certain period?

Exactly! After the specified cycles of immersion, we check how much weight has been lost. Why do we use two different chemicals?

Because they simulate different weathering conditions?

Correct again! This allows us to understand how aggregates will perform under varied environmental scenarios.

Impact on Road Durability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about the implications of the Soundness Test. If a sample fails and has a weight loss greater than the specified limits, what does that mean?

It means the aggregate isn’t suitable for use in the road construction!

That's right! A failure indicates poor durability, which could lead to pavement distress in real-world conditions. Can anyone think of how this might affect project costs?

If we have to replace materials more often, it will increase costs significantly.

Excellent point! Ensuring that we use sound aggregates can prevent higher maintenance and repair costs down the line.

Real-Life Examples of Soundness Issues

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s take a moment to consider real-world examples. Does anyone know any cases where poor aggregate soundness led to road failures?

I read about a highway that had to be repaired because the aggregates were not durable enough!

Good example! Such instances emphasize that proper testing and selection of aggregates are critical. What could have been done differently to avoid that situation?

They could have conducted the Soundness Test beforehand to ensure durability.

Absolutely! Preventive measures, like conducting soundness tests, can save both time and resources in construction projects.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Soundness Test evaluates the ability of aggregates to withstand weathering processes over time, particularly under freeze-thaw and wet-dry conditions. It employs sodium sulfate and magnesium sulfate to determine acceptable weight loss limits to ensure the reliability of road materials.

Detailed

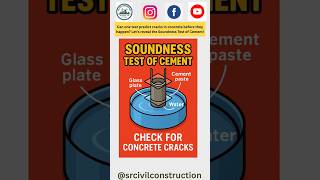

Soundness Test

The Soundness Test, outlined in IS 2386 (Part 5), focuses on evaluating the durability of road aggregates when subjected to weathering conditions. Specifically, it assesses how well aggregates can endure cycles of freezing and thawing, as well as wetting and drying, which are critical in various environmental conditions.

The testing process involves using sodium sulfate and magnesium sulfate, two chemical agents that mimic these weathering effects. The soundness of aggregates is measured by observing the loss in weight after submersion in these solutions, where the acceptable limits are set at a maximum of 12% weight loss for sodium sulfate and 18% for magnesium sulfate.

This test is essential for ensuring that the aggregates used in road and pavement construction maintain their integrity and performance capabilities over time, ultimately affecting the lifespan and durability of the resulting structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Soundness Test Definition

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Definition: Resistance to weathering, especially under freeze-thaw and wetting-drying cycles.

Detailed Explanation

The soundness test measures how well aggregates can withstand various weather conditions. Specifically, it evaluates their durability against repeated cycles of freezing and thawing, as well as wetting and drying. These conditions can cause materials to break down over time, impacting their effectiveness in road construction.

Examples & Analogies

Imagine how a water bottle left in the freezer can crack if the water inside freezes and expands. Similarly, aggregates that cannot resist such cycles can degrade and lose their effectiveness in construction.

Testing Methods for Soundness

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Test: Sodium Sulfate/Magnesium Sulfate Soundness Test.

Detailed Explanation

The soundness of aggregates is assessed through a specific test using sodium sulfate or magnesium sulfate. In this test, aggregates are repeatedly immersed in a solution of these compounds to simulate the weathering process. After several cycles of soaking and drying, the loss of weight is measured to determine their durability.

Examples & Analogies

Think of how a sponge behaves when it is soaked in water, then dried. If repeatedly soaked and dried, some sponges degrade or lose their shape. Similarly, this test helps identify aggregates that may not hold up well under similar stress.

Soundness Value Specification

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Soundness Value: Loss in weight should not exceed 12% for sodium sulfate and 18% for magnesium sulfate.

Detailed Explanation

During the soundness test, the aggregates should not lose too much weight. For those tested with sodium sulfate, the loss should be limited to 12%, while for magnesium sulfate, it should not exceed 18%. This specification ensures that only high-quality, durable aggregates are used in construction, contributing to the longevity of the road.

Examples & Analogies

Consider how a piece of fruit might spoil over time. If it loses too much mass, it becomes unpalatable and unusable. In construction, aggregates that surpass weight loss limits may similarly fail to provide the necessary strength and durability.

Key Concepts

-

Soundness Test: Measures aggregate durability under freeze-thaw and wet-dry conditions.

-

Sodium Sulfate: Used for durability testing, max 12% weight loss.

-

Magnesium Sulfate: Used for durability testing, max 18% weight loss.

-

Weight Loss: Key indicator of aggregate soundness.

Examples & Applications

An aggregate sample showed a 15% weight loss in sodium sulfate, failing to meet the acceptable standard.

A well-tested aggregate had less than 10% weight loss during the soundness test, proving suitable for road construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Sodium sulfate, magnesium too, help us know if aggregates are true.

Stories

Once a builder thought he knew, but his roads fell to pieces – oh what a view! He checked the soundness, for withstanding the load, he learned his lesson, strong aggregates were owed.

Memory Tools

Remember: Soundness tests for aggregates! Sodium and magnesium are the key – if weight loss is too much, then don't let it be.

Acronyms

SAMS - Soundness After Measuring Sodium.

Flash Cards

Glossary

- Soundness Test

A test to determine the durability of aggregates against weathering, using sodium and magnesium sulfate.

- Sodium Sulfate

A chemical used in the soundness test to assess aggregate durability under weathering conditions.

- Magnesium Sulfate

Another chemical used in the soundness test, providing insights into the weathering resistance of aggregates.

- Weight Loss

The measurement taken post-test to determine how much of the aggregate has deteriorated after exposure to the soundness test.

Reference links

Supplementary resources to enhance your learning experience.