Requirements of Road Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Strength of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore the strength requirement of aggregates. Strength refers to the ability of aggregate particles to resist crushing under heavy loads. Can anyone tell me how we measure this strength?

Is it through the Aggregate Crushing Value test?

Exactly! The ACV test helps determine the percentage of crushed materials. For wearing surfaces, what do you think the acceptable limit is?

It should be 30%, right?

Correct! And for different applications like bituminous macadam and base courses, the limits change. Remember the acronym '30-35-40' for our limits! Always review these during your preparation.

Hardness and Toughness Levels

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's dive into hardness and toughness. Hardness tells us how resistant aggregates are to wear, usually measured through the Los Angeles Abrasion Test. What do you think is a good maximum value for this test?

Maybe about 35% for bituminous mixes?

Right on the mark! Since high abrasion could weaken the pavement. Now, what do we mean by toughness?

It's the ability to resist impact loads, right?

Correct! And we measure this using the Aggregate Impact Value test. We want AIV to be less than 30% for surfacing. Let’s summarize: ACV for strength, LA for hardness, and AIV for toughness. Remember those tests!

Durability and Shape of Particles

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In terms of durability, the resistance to weathering is crucial. How do we measure the soundness of aggregates?

We can use the Sodium Sulfate test, right?

Exactly! And the loss in weight should not exceed 12% for sodium sulfate. But why is the shape of aggregates important?

I think it affects how well they interlock and compact together.

That's right! We prefer angular shapes over flaky or elongated ones. Always look for a Flakiness Index below 15% for surface courses. Let’s recap: Durability is key to performance; shapes affect how well they perform structurally.

Adhesion and Water Absorption

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Adhesion with bitumen is another critical property. Why do you think it’s necessary for road aggregates?

To prevent stripping of the bitumen, I assume?

Correct! We measure this through the Static Immersion Test. Also, we need to consider water absorption—what’s the ideal maximum percentage?

It should be lower than 2%.

Exactly! High water absorption can lead to a poor mix design. So, knowing these properties is vital for our road construction projects. Integrate this knowledge into practical applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The requirements of road aggregates are based on their strength, hardness, toughness, durability, shape, adhesion, water absorption, and specific gravity. These properties are critical for ensuring that the aggregates can withstand environmental and traffic-related stresses.

Detailed

Requirements of Road Aggregates

Aggregates are crucial in road construction, comprising a significant portion of the materials used in pavements. The suitability of these aggregates is determined through various engineering properties, which dictate their performance under load and environmental conditions.

Key Properties of Road Aggregates

- Strength: This refers to the aggregate's ability to resist crushing under heavy loads. Key tests include Aggregate Crushing Value (ACV) and the Los Angeles Abrasion Test, with specific limits for different uses (e.g., ACV ≤ 30% for wearing surfaces).

- Hardness: Represents the resistance to wear and abrasion, typically evaluated by the same Los Angeles Abrasion Test. A maximum abrasion value of 30-35% is desirable for bituminous mixes.

- Toughness: The ability of aggregates to withstand impact and dynamic loads is assessed through the Aggregate Impact Value (AIV) test, with standards requiring AIV ≤ 30% for surfacing.

- Durability and Soundness: These properties measure the aggregate's resistance to weathering, specifically considering freeze-thaw and wetting-drying cycles. Loss in weight should not exceed 12% (sodium sulfate) or 18% (magnesium sulfate).

- Shape of Particles: Well-shaped aggregates facilitate better interlocking and compaction. Tests for flakiness and elongation index are applied, with flakiness index (FI) needing to be below 15% for surface courses.

- Adhesion with Bitumen: Good adhesion to bitumen is necessary to prevent stripping, tested via the Static Immersion Test. Anti-stripping agents may be utilized to improve this property.

- Water Absorption and Specific Gravity: Ideally, water absorption should be below 2%, with a specific gravity range of 2.5 to 3.0, which impacts mix design and quality control.

Understanding these requirements ensures that road aggregates perform effectively under various traffic and environmental conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Aggregate Assessment

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The suitability of aggregates for road construction is assessed based on specific engineering properties that determine their behavior under traffic loading, weathering, and construction conditions.

Detailed Explanation

Assessing the suitability of aggregates is crucial because aggregates play a significant role in the strength and durability of road structures. Specific engineering properties are measured to understand how aggregates will behave when subjected to loads from vehicles, changes in weather, and the conditions during construction. This evaluation ensures that the right type of aggregate is used for various parts of road construction, ultimately contributing to the longevity and safety of the roadway.

Examples & Analogies

Think of selecting road aggregates like choosing ingredients for a recipe. Just as different ingredients affect the taste, texture, and quality of a dish, the properties of aggregates — such as strength and hardness — will directly impact how well a road withstands traffic and environmental factors.

Strength of Aggregates

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.1 Strength

- Definition: The ability of aggregate particles to resist crushing under heavy traffic loads.

- Tests Conducted:

- Aggregate Crushing Value (ACV)

- Los Angeles Abrasion Test

- Impact Value Test

- Specifications:

- For wearing surfaces: ACV ≤ 30%

- For bituminous macadam: ACV ≤ 35%

- For base courses: ACV ≤ 40%

Detailed Explanation

The strength of aggregates refers to their capability to withstand crushing forces when heavy vehicles pass over them. To assess this, engineers conduct several tests: the Aggregate Crushing Value test evaluates how resistant the aggregates are to crushing, the Los Angeles Abrasion Test checks their wear over time, and the Impact Value Test measures how well they hold up against sudden stresses. Standards are set so that for different layers of roads, aggregates shouldn't exceed specific crushing values, ensuring they can handle the required load.

Examples & Analogies

Think of the strength of aggregates like the weight capacity of a shelf. If a shelf can only hold so much weight before it collapses, similar tests help determine how much weight (or traffic) the road aggregates can handle without failing.

Hardness of Aggregates

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

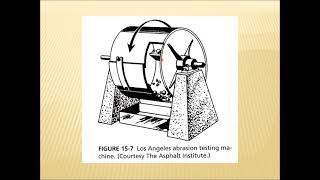

6.1.2 Hardness

- Definition: Resistance to abrasion and wear.

- Test: Los Angeles Abrasion Test

- Typical Value:

- Max Abrasion Value for bituminous mix: 30–35%

Detailed Explanation

Hardness measures how well aggregates resist abrasion, which is the wear caused by friction against traffic and environmental elements. The Los Angeles Abrasion Test is commonly conducted to evaluate this property. A maximum abrasion value of 30-35% is recommended for aggregates used in bituminous mixtures to ensure they maintain their integrity over time and don't break down under stress.

Examples & Analogies

Consider a pair of shoes. If they have a durable outer material, they will withstand wear from walking better than those made from softer materials. Similarly, harder aggregates will endure the pounding of traffic without losing their strength.

Toughness of Aggregates

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.3 Toughness

- Definition: Ability to resist impact and dynamic loads.

- Test: Aggregate Impact Value (AIV)

- Standard: AIV ≤ 30% for surfacing

Detailed Explanation

Toughness indicates how well aggregates can withstand sudden shocks or dynamic forces. This is especially important for roads that experience heavy traffic and varying weather conditions. The Aggregate Impact Value test measures this property, with a standard that outlines a maximum impact value to ensure the aggregate remains intact under stress.

Examples & Analogies

Think of toughness like a football player's ability to take hits. The better a player is at resisting and continuing after hits, the tougher they are. Similarly, tougher aggregates handle impact better, ensuring the road remains safe and intact.

Durability and Soundness of Aggregates

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.4 Durability and Soundness

- Definition: Resistance to weathering, especially under freeze-thaw and wetting-drying cycles.

- Test: Sodium Sulfate/Magnesium Sulfate Soundness Test

- Soundness Value: Loss in weight should not exceed 12% for sodium sulfate and 18% for magnesium sulfate.

Detailed Explanation

Durability and soundness refer to how well aggregates withstand the effects of weather, such as freeze-thaw cycles and wetting-drying changes. The Sodium Sulfate and Magnesium Sulfate soundness tests check for this resistance by measuring any weight loss. A specified weight loss limit helps ensure that aggregates will last over time, despite harsh weather conditions.

Examples & Analogies

Imagine a sponge left outside in the rain, then freezing overnight. If it continues to break down every time it freezes, it won't last long. Similarly, aggregates that can't withstand weathering will fail quicker in road construction.

Shape of Particles

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.5 Shape of Particles

- Importance: Well-shaped aggregates offer better interlocking and compaction.

- Types: Angular, flaky, elongated, rounded

- Tests:

- Flakiness Index (FI)

- Elongation Index (EI)

- Specifications:

- FI should be less than 15% for surface courses.

Detailed Explanation

The shape of aggregate particles is vital for how they fit together, influencing the stability and strength of the road. Well-shaped aggregates, especially angular ones, interlock better and compact more efficiently. Tests like the Flakiness Index (FI) and Elongation Index (EI) measure these attributes, and specific limits on flakiness help ensure proper material quality for road surfaces.

Examples & Analogies

Think of building with LEGO bricks: the shapes of the bricks allow them to fit together more snugly when they are angular and firm. If all the blocks were flat, it would be hard to stack them properly, similar to how well-shaped aggregates create stronger pavements.

Adhesion with Bitumen

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.6 Adhesion with Bitumen

- Requirement: Aggregates must have good affinity to bitumen to resist stripping.

- Test: Static Immersion Test / Stripping Value Test

- Improvement: Anti-stripping agents or lime can be used to improve adhesion.

Detailed Explanation

Good adhesion between aggregates and bitumen is essential to prevent the aggregates from separating from the pavement. Static Immersion and Stripping Value tests determine how well aggregates bond with bitumen. In cases where adhesion is weak, additives like anti-stripping agents or lime are used to enhance this property.

Examples & Analogies

Consider how glue works: if it doesn't adhere well to materials, they won't stick together effectively. In road construction, if aggregates don’t bond well with bitumen, the surface can peel or degrade quickly, similar to a poorly glued project falling apart.

Water Absorption and Specific Gravity

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

6.1.7 Water Absorption and Specific Gravity

- Water Absorption: Lower absorption indicates better performance; max 2%.

- Specific Gravity: Normally between 2.5 to 3.0 for road aggregates.

- Importance: Affects the mix design and quality control.

Detailed Explanation

Water absorption refers to how much water the aggregates can take in, which affects their performance. Lower absorption is better, with a maximum of 2% recommended. Specific gravity indicates the density of the aggregates, typically between 2.5 and 3.0. Both properties are critical as they influence the overall mix design and quality during road construction.

Examples & Analogies

Think of a sponge again; if it absorbs too much water, it becomes soggy and less effective. Similarly, aggregates that absorb excessive water might weaken and perform poorly in road applications.

Key Concepts

-

Strength: Aggregates must withstand heavy loads without crushing.

-

Hardness: Resistance to wear is crucial for long-lasting pavements.

-

Toughness: Ability to endure impact and dynamic loads.

-

Durability: Resistance to weathering preserves aggregate integrity.

-

Adhesion: Good binding with bitumen improves road lifespan.

-

Water Absorption: Low absorption rates enhance overall performance.

Examples & Applications

Concrete aggregates with an ACV of 25% are suitable for high-traffic roads, ensuring longevity.

Aggregates used for thin asphalt overlays typically have a maximum AIV of 30% to ensure they can handle dynamic loads.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For strength, it’s ACV, below thirty for the best you see. Toughness next, AIV, at thirty or under will keep your road alive.

Stories

Imagine a road named 'Aggregates Way', where strength kept cars from going astray, shaped like angles, solid and dark, preserving its structure like Noah’s ark.

Memory Tools

Remember the acronym 'SHAT-W' for Strength, Hardness, Adhesion, Toughness, Water absorption for the key properties.

Acronyms

Use the word 'CHAW' to remember

Crushing strength

Hardness

Adhesion

Water Absorption.

Flash Cards

Glossary

- Aggregate Crushing Value (ACV)

A test to determine the strength of aggregates under crushing loads.

- Los Angeles Abrasion Test

A test to measure the hardness and abrasion resistance of aggregates.

- Aggregate Impact Value (AIV)

A test that measures the toughness or resistance of aggregates to impact.

- Soundness

The ability of aggregates to resist weathering, assessed through loss in weight during specific tests.

- Shape Index

A measure of the geometry of aggregates, including flakiness and elongation.

- Adhesion

The affinity that aggregates have for bitumen, affecting the quality of the pavement.

- Water Absorption

The amount of water an aggregate can absorb, impacting its performance in the mix.

- Specific Gravity

The ratio of the mass of an aggregate to the mass of an equal volume of water, indicating density.

Reference links

Supplementary resources to enhance your learning experience.