Strength

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition of Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're exploring the concept of 'Strength' in road aggregates. Can anyone tell me what strength means in this context?

Is it about how well the aggregates can carry heavy loads?

Exactly! It refers to the ability of aggregate particles to resist crushing under heavy traffic loads. This characteristic is essential for the longevity of pavements.

What tests do we perform to measure this strength?

Great question! We conduct the Aggregate Crushing Value test, the Los Angeles Abrasion Test, and the Impact Value Test.

What does the Aggregate Crushing Value test specifically measure?

The ACV measures the resistance of aggregate to crushing under a compressive load. It’s crucial for determining how suitable aggregates are for different applications!

What are the specifications for different pavement types?

For example, for wearing surfaces, the ACV must be ≤ 30%. For bituminous macadam, it's ≤ 35%, and for base courses, ≤ 40%. This ensures adequate strength for their specific use.

To recap, strength in aggregates is their ability to withstand heavy loads. Remember the tests and specifications as they ensure we choose the right materials for our pavements!

Tests for Strength

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the tests we use to evaluate the strength of aggregates. Who can name one of them?

The Los Angeles Abrasion Test?

Correct! This test determines an aggregate's resistance to wear due to abrasion. What about the others?

Is the Aggregate Crushing Value test similar?

Yes, it is! The ACV focuses on measuring the degree to which aggregates can withstand crushing forces. Can anyone remember what the importance of these tests is?

They help ensure the materials are strong enough for the type of pavement we are building.

Precisely! These tests are vital to guarantee that our aggregates will perform well under the expected traffic loads. Great job!

In summary, the Los Angeles Abrasion Test and the Aggregate Crushing Value test are essential to determine aggregate strength. Always remember their roles!

Significance of Strength Specifications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now focus on the significance of setting strength specifications. Why do we impose different ACV limits for various pavement types?

Maybe because different pavements experience different levels of stress?

Exactly! Wear and tear varies based on traffic loads and environmental conditions. For example, the highest strength is required for wearing surfaces, where traffic is most direct.

So, if we use an aggregate with too high or too low an ACV, what could happen?

If we choose aggregates with a high ACV for wearing surfaces, they may not survive under load over time. Conversely, aggregates with low ACV may chip and create unsafe conditions on the road.

So, specifications really help ensure roads are safe and durable?

That's right! Specifications are crucial in guiding our choice of materials and ensuring long-lasting, safe pavements. Remember the importance of these limits in your future projects!

To summarize, specifications for aggregate strength are necessary for balancing safety and durability across the different pavements.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Strength is a critical property of road aggregates, defined as their resistance to crushing under heavy traffic loads. Various tests, including the Aggregate Crushing Value (ACV) and Los Angeles Abrasion Test, assess strength, and specific limits are set to ensure performance standards in different pavement applications.

Detailed

Strength

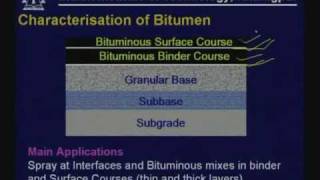

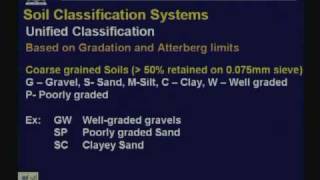

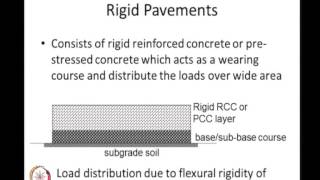

Strength is one of the essential properties of road aggregates, crucial for ensuring the durability and performance of pavements under traffic loading. It is defined as the ability of aggregate particles to resist crushing when subjected to heavy loads. The assessment of aggregate strength is executed through several standardized tests. The key tests include the Aggregate Crushing Value (ACV), which measures the strength and the resistance to crushing of aggregates, the Los Angeles Abrasion Test that determines the wear resistance under mechanical influence, and the Impact Value Test that assesses their toughness.

Depending on the specific application—whether it's a wearing surface, bituminous macadam, or base courses—different strength specifications are set. For example, for wearing surfaces, the acceptable ACV is ≤ 30%, for bituminous macadam ≤ 35%, and for base courses ≤ 40%. These specifications ensure that the materials used can withstand traffic loads and environmental conditions, ultimately safeguarding the longevity and safety of road pavements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Strength

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The ability of aggregate particles to resist crushing under heavy traffic loads.

Detailed Explanation

Strength in aggregates refers to how well the particles hold up under pressure, especially from the weight of vehicles. In a road, when heavy trucks pass over it, there is a lot of force applied to the pavement. If the aggregates have high strength, they won’t break down or crush easily, ensuring the road remains intact and durable.

Examples & Analogies

Think of the aggregate particles like the bones in a body. Just as strong bones help a person carry weight and prevent breaking, strong aggregate helps the road support the heavy load from cars and trucks without crumbling.

Tests Conducted for Strength

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Tests Conducted:

- Aggregate Crushing Value (ACV)

- Los Angeles Abrasion Test

- Impact Value Test

Detailed Explanation

To measure the strength of aggregates, engineers perform several tests:

1. Aggregate Crushing Value (ACV): This test determines how much force the aggregate can withstand before crushing.

2. Los Angeles Abrasion Test: This assesses resistance to wear and tear when aggregates are subjected to rolling and impacting during road use.

3. Impact Value Test: This evaluates how well aggregates can handle sudden shocks or impacts, simulating conditions like the impact from tires.

Each test provides valuable information about how the aggregates will behave under real-world conditions.

Examples & Analogies

Imagine testing different bags of potatoes by dropping weights on them. The bag that doesn't break under heavy weights (like ACV) or shows minimal damage after being rolled around (like the Los Angeles Abrasion Test) would be considered stronger and better for making a durable road.

Specifications for Aggregate Strength

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Specifications:

- For wearing surfaces: ACV ≤ 30%

- For bituminous macadam: ACV ≤ 35%

- For base courses: ACV ≤ 40%

Detailed Explanation

Specifications set limits for how weak aggregates can be based on their usage:

1. For wearing surfaces (the top layer of a road): The Aggregate Crushing Value (ACV) should be 30% or less. This means that these aggregates can only lose up to 30% of their strength when tested.

2. For bituminous macadam (a type of road structure): The ACV can be higher at 35%.

3. For base courses (the layer beneath the surface): An ACV of 40% is acceptable. These specifications ensure that the aggregates used in each layer can adequately handle the expected traffic loads.

Examples & Analogies

Imagine a body of water. If you have a shallow pond (like the wearing surface), it can only support lightweight boats (having a lower ACV requirement). However, if you have a deeper lake (like the base course), it can accommodate larger vessels but still needs to be strong enough so that the boats don’t get knocked over easily.

Key Concepts

-

Strength: The ability of aggregate particles to resist crushing under traffic loads.

-

Aggregate Crushing Value (ACV): A key measure of the strength of aggregates, defined by specific limit values.

-

Los Angeles Abrasion Test: A test to evaluate wear resistance.

-

Impact Value Test: A measure of the toughness of aggregates under impact.

Examples & Applications

For paving a heavily trafficked road, aggregates with an ACV of ≤ 30% are specified to ensure sufficient strength.

Using aggregates that fail the abrasion test can result in premature wear of the pavement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Aggregate strength, don't let it bend, for strong pavements, it's your best friend!

Stories

Imagine a strong knight (strength) guarding a kingdom (pavement). If the knight can't withstand the heavy armor (traffic loads), the kingdom won't last long. So, tests ensure the knight is strong enough!

Memory Tools

The acronym ACV: Aggregate Crushing Value is your guide for pavement selection.

Acronyms

STRENGTH

Strong Tests Remember Ensure No Gravel Toughness Happily.

Flash Cards

Glossary

- Aggregate Crushing Value (ACV)

A test to measure the resistance of aggregate to crushing under a compressive load.

- Los Angeles Abrasion Test

A test that determines the wear resistance of aggregates through abrasion.

- Impact Value Test

A test used to assess the toughness of aggregates under impact.

- Specifications

Defined limits or criteria that materials must meet for specific applications.

Reference links

Supplementary resources to enhance your learning experience.