Road Aggregates – Requirements and Types

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Strength of Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will dive into the requirements for road aggregates, starting with strength. Can anyone tell me why strength is crucial for aggregates used in road construction?

I think strength is important because it helps the aggregate handle heavy loads without crushing.

Exactly! The strength of an aggregate is crucial as it affects the overall load-bearing capacity of the pavement. Strength is measured through tests like the Aggregate Crushing Value or ACV. What do you think is an acceptable ACV value for wearing surfaces?

Isn’t it 30% or less?

You got it! An ACV of 30% or less is required for wearing surfaces, while it can be slightly more for base courses. Remember this—you can use the acronym *ACV* to stand for *Aggregate Crush Value* when referring to this measure. Can anyone think of why it might differ for other types of surfaces?

Maybe because different layers need to handle different amounts of weight?

Precisely! Different pavement types experience different traffic loads, necessitating varied strength specifications. Let’s wrap up this session with a quick summary: Strength is essential for aggregate performance in road construction, and we assess it mainly through ACV testing.

Exploring Hardness and Toughness in Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Continuing our discussion, who can elaborate on the hardness of aggregates?

Is it about how well the aggregate can resist wear and tear?

That's correct! Hardness refers to resistance against abrasion. The Los Angeles Abrasion Test determines this property. For bituminous mixes, standard abrasion values should ideally be between 30-35%. What about toughness? How is it different from hardness?

I believe toughness relates to how well the aggregate can withstand impacts rather than just wearing down.

Exactly! Toughness measures how aggregates resist dynamic loads, assessed by the Aggregate Impact Value, or AIV. A standard value for surfacing is AIV less than or equal to 30%. Why do you think this distinction between hardness and toughness is important?

I think it helps ensure different properties tailor to different performance needs under various conditions.

Right again! Tailoring these properties helps ensure optimal pavement performance under diverse environmental and traffic conditions. Let’s remember: hardness is about wear, while toughness is about impact.

The Role of Water Absorption and Specific Gravity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we'll discuss water absorption and specific gravity. Can anyone explain why these properties are important?

Isn't it because it affects how well the aggregate will perform in a mixture?

Absolutely! Low water absorption is preferred for how aggregates perform in mixes. What’s the maximum percentage for water absorption ideally recommended?

I think it's around 2%?

Exactly! And what about specific gravity? What range should we expect for road aggregates?

It’s usually between 2.5 to 3.0, right?

You’ve got it! These properties help determine mix design and quality control, ultimately affecting pavement durability and performance. Remember the mnemonic: *Water Equals Stability* to connect water absorption and performance!

Types of Aggregates Based on Size and Geological Origin

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift our focus to types of aggregates. How do we classify aggregates based on their size?

Coarse aggregates are retained on 4.75 mm sieves, while fine aggregates pass through that sieve.

Correct! This classification affects their usage; for instance, coarse aggregates are used in the base course. What about fillers? What defines them?

Fillers pass through the 75 µm sieve and help improve mix gradation.

Very well explained! Now, let's look at the geological origin. Besides size, how do rocks differ based on their formation type?

Igneous rocks are hard and strong, while sedimentary might be less durable.

Great observation! Each type plays a unique role depending on construction needs. When thinking of geological classifications, remember: *I See Strong* for Igneous, *Soft Sands* for Sedimentary, and *Extreme Density* for Metamorphic lands!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Aggregates comprise a significant volume of road materials, and understanding their requirements—such as strength, hardness, toughness, and durability—is key to effective pavement performance. This section also classifies aggregates by origin, size, shape, and geological formation, highlighting their applications in construction.

Detailed

Road Aggregates – Requirements and Types

Aggregates are pivotal in road construction, constituting about 70–90% of various pavement types. The properties and types of aggregates influence the strength and durability of roads subjected to environmental and traffic stresses. This section delves into:

Requirements of Road Aggregates

- Strength: Measured by tests such as the Aggregate Crushing Value (ACV) with specified limits for different pavements to ensure resistance under heavy loads.

- Hardness: Aggregates should resist abrasion, assessed by the Los Angeles Abrasion Test, with acceptable values varying for different mixes.

- Toughness: Indicates resistance to impact loads, where standards such as Aggregate Impact Value (AIV) must be met.

- Durability and Soundness: Resistance to environmental weathering is assessed through soundness tests, with established limits for weight loss.

- Particle Shape: Better interlocking and compaction is observed with well-shaped aggregates, measured using the Flakiness and Elongation Indexes.

- Adhesion with Bitumen: Important for preventing stripping of bitumen, assessed through the Static Immersion Test.

- Water Absorption and Specific Gravity: Influences mix design, with specific limits on absorption percentage and specific gravity values set for road aggregates.

Types of Road Aggregates

They are categorized by:

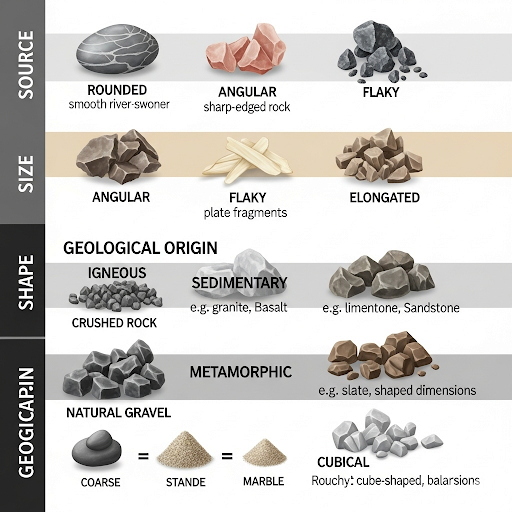

- Source: Natural, Artificial, or Recycled, each with unique advantages and applications.

- Size: Classified as Coarse, Fine, or Filler materials based on sieve sizes.

- Shape: Includes Rounded, Angular, Flaky, Elongated and Cubical aggregates, each affecting the performance.

- Geological Origin: Identified as Igneous, Sedimentary, or Metamorphic, influencing their physical properties and suitability for various loads.

This comprehensive analysis of aggregate requirements and types ensures informed decisions in road construction for enhanced durability and performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Road Aggregates

Chapter 1 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates form a significant component of road construction materials, making up about 70–80% of the volume of bituminous pavements and up to 90% in cement concrete pavements. The strength, durability, and performance of pavements are heavily influenced by the properties and types of aggregates used. Understanding their requirements and classifications is crucial for ensuring optimal pavement behavior under traffic loading and environmental conditions.

Detailed Explanation

Road aggregates are the materials used in the construction of roads and pavements. They make up a large part of the volume used in both bituminous and cement concrete pavements. The performance and durability of these pavements greatly depend on the characteristics of the aggregates. For effective construction, it's important to understand the types of aggregates and their specifications, which help in maintaining good pavement quality under various conditions and loads.

Examples & Analogies

Think of road aggregates as the foundation of a house. Just like a house needs a strong and stable foundation to support the walls and roof, roads need strong aggregates to support the traffic and withstand weather conditions.

Requirements of Road Aggregates

Chapter 2 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The suitability of aggregates for road construction is assessed based on specific engineering properties that determine their behavior under traffic loading, weathering, and construction conditions.

Detailed Explanation

To ensure the right type and quality of aggregates for road construction, several properties are evaluated. These include strength, hardness, toughness, durability, particle shape, adhesion with bitumen, water absorption, and specific gravity. Each of these properties contributes to how well the aggregates will perform when used in pavements. Assessing these properties helps in choosing aggregates that can withstand the stresses applied by vehicles and environmental factors.

Examples & Analogies

Assessing aggregate properties is similar to testing different types of shoes before a big hike. You want shoes that can resist wear (hardness), take impacts (toughness), and not get ruined by rain (durability) to ensure a comfortable and safe hike.

Strength of Aggregates

Chapter 3 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Strength: The ability of aggregate particles to resist crushing under heavy traffic loads. Tests Conducted: Aggregate Crushing Value (ACV), Los Angeles Abrasion Test, Impact Value Test. Specifications: For wearing surfaces: ACV ≤ 30%, for bituminous macadam: ACV ≤ 35%, for base courses: ACV ≤ 40%.

Detailed Explanation

Strength refers to how well aggregates can withstand crushing from heavy traffic loads. Several standardized tests, such as the Aggregate Crushing Value (ACV) test, are performed to measure this strength. The ACV specifies limits depending on the application, with lower values required for surfaces subjected to direct traffic. This ensures that the aggregates will not break down or deform under heavy loads, maintaining structural integrity.

Examples & Analogies

Imagine carrying a heavy backpack while hiking. If the backpack can withstand the weight without tearing (strong), you can hike comfortably. But if it breaks under pressure (weak), your hike will be disrupted. Similarly, in road construction, aggregates need to be strong enough to handle traffic loads.

Hardness of Aggregates

Chapter 4 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Hardness: Resistance to abrasion and wear. Test: Los Angeles Abrasion Test. Typical Value: Max Abrasion Value for bituminous mix: 30–35%.

Detailed Explanation

Hardness measures how resistant aggregates are to wear and tear from friction. This is tested using the Los Angeles Abrasion Test, which simulates the impact and abrasion caused by traffic. The results help determine if the aggregates can maintain their size and shape over time, as excessive wear can weaken the pavement.

Examples & Analogies

Think of hardness like the surface of a new smartphone screen. A harder screen can withstand scratches from keys and coins without showing damage. Similarly, aggregates that are hard endure the wear from vehicles without breaking down.

Toughness of Aggregates

Chapter 5 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Toughness: Ability to resist impact and dynamic loads. Test: Aggregate Impact Value (AIV). Standard: AIV ≤ 30% for surfacing.

Detailed Explanation

Toughness measures an aggregate's ability to withstand sudden impacts and stress without breaking. This characteristic is critical for road materials as they often face dynamic loads from vehicles accelerating, braking, and turning. The Aggregate Impact Value (AIV) test assesses this toughness, with a required standard to ensure reliability in road surfaces.

Examples & Analogies

Consider toughness like a football player’s ability to withstand tackles during a game. A tough player can absorb blows without getting injured. Similarly, tough aggregates are essential for roads to survive the daily impact from heavy vehicles.

Durability and Soundness

Chapter 6 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Durability and Soundness: Resistance to weathering, especially under freeze-thaw and wetting-drying cycles. Test: Sodium Sulfate/Magnesium Sulfate Soundness Test. Soundness Value: Loss in weight should not exceed 12% for sodium sulfate and 18% for magnesium sulfate.

Detailed Explanation

Durability and soundness relate to how well aggregates can resist environmental changes such as wetting-drying and freeze-thaw cycles. This is tested using sulfate soundness tests. Results indicate how much weight aggregates can lose under these conditions, which helps in determining their suitability for various weather environments.

Examples & Analogies

Imagine leaving a fountain filled with gravel outside in winter and summer. Over time, if the gravel breaks down due to temperature changes (loss in weight), it indicates low durability. Aggregates need to be resilient like good outdoor furniture that withstands different weather without falling apart.

Shape of Aggregates

Chapter 7 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Shape of Particles: Well-shaped aggregates offer better interlocking and compaction. Types: Angular, flaky, elongated, rounded. Tests: Flakiness Index (FI), Elongation Index (EI). Specifications: FI should be less than 15% for surface courses.

Detailed Explanation

The shape of aggregates affects how well they fit together and how strong the pavement will be. Angular aggregates interlock better, providing more stability, while rounded aggregates have less grip. Tests like the Flakiness Index (FI) and Elongation Index (EI) help evaluate the shape of aggregates to ensure they meet construction standards.

Examples & Analogies

Think of puzzle pieces. If the edges are straight and fit nicely together (angular), you create a strong picture. If the pieces are round and can’t connect (rounded), the puzzle remains weak. Similarly, well-shaped aggregates help create a strong road base.

Adhesion with Bitumen

Chapter 8 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Adhesion with Bitumen: Aggregates must have good affinity to bitumen to resist stripping. Test: Static Immersion Test / Stripping Value Test. Improvement: Anti-stripping agents or lime can be used to improve adhesion.

Detailed Explanation

Adhesion refers to how well aggregates stick to bitumen, which is essential for the durability of asphalt pavements. Poor adhesion can lead to stripping, where the bitumen separates from the aggregates. Tests assess the adhesion properties of the aggregates to ensure they bond well with bitumen, and if necessary, chemical agents can enhance this bond.

Examples & Analogies

Imagine trying to stick tape to a wet surface – it won’t hold well. Good adhesion is similar; aggregates need to bond firmly with bitumen, just like dry surfaces allow tape to stick properly.

Water Absorption and Specific Gravity of Aggregates

Chapter 9 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Water Absorption: Lower absorption indicates better performance; max 2%. Specific Gravity: Normally between 2.5 to 3.0 for road aggregates. Importance: Affects the mix design and quality control.

Detailed Explanation

Water absorption measures how much water aggregates can take in, which affects their performance in concrete mixes. Lower absorption means aggregates will not absorb too much water, leading to better pavement durability. Specific gravity provides insight into the density of the aggregates and is important for mix design.

Examples & Analogies

Think of a sponge versus a rock. A sponge absorbs water and becomes heavy, while a rock stays dry. Rock-like aggregates (lower absorption) perform better in road construction than sponges (higher absorption).

Types of Road Aggregates

Chapter 10 of 10

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Aggregates are classified based on their origin, size, shape, and geological formation. The selection depends on the pavement type, traffic intensity, and climatic conditions.

Detailed Explanation

There are different types of aggregates based on their source (natural, artificial, recycled), size (coarse, fine, filler), shape (rounded, angular, flaky), and geological origin (igneous, sedimentary, metamorphic). The selection of aggregate type is crucial as it ensures the pavement's suitability based on intended use, traffic levels, and environmental considerations.

Examples & Analogies

Choosing the right aggregate is similar to selecting the right ingredients for a recipe. For a cake, you need flour, sugar, and eggs in the right amounts (types of aggregates) for the best taste (pavement performance).

Key Concepts

-

Strength: The ability of aggregates to resist crushing under heavy loads, assessed by tests like ACV.

-

Hardness: Resistance to abrasion and wear, measured using the Los Angeles Abrasion Test.

-

Toughness: The ability to resist impact loads, measured by the Aggregate Impact Value.

-

Durability: Aggregates must withstand weathering cycles, with specific tests to ensure soundness.

-

Shape of Particles: Well-shaped aggregates improve interlocking and compaction.

-

Adhesion with Bitumen: The bond between aggregates and bitumen is crucial for effective pavement.

-

Water Absorption and Specific Gravity: These affect the overall quality and performance of the mix.

Examples & Applications

An example of a natural aggregate is gravel from river deposits, which is commonly used in concrete.

Artificial aggregates such as crushed bricks are often used in low-traffic pavements or sub-bases.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For aggregates tough and strong, keep the crushing low, that's where they belong!

Stories

Imagine a road made of cookies—using soft, sugary ingredients leads to a crumbly path! Strength and proper properties are necessary to ensure our roads aren't dessert!

Memory Tools

To remember ACV, AIV, and Durability, think A Good Car Drives—for Aggregate Crushing Value, Aggregate Impact Value, and Soundness.

Acronyms

Use *SHIDA* to remember

- Strength

- Hardness

- Impact

- Durability

- Adhesion.

Flash Cards

Glossary

- Aggregate Crushing Value (ACV)

A measure of the strength of aggregate by determining their resistance to crushing.

- Los Angeles Abrasion Test

A test to measure the hardness and abrasion resistance of aggregates.

- Toughness

The ability of an aggregate to withstand impact and dynamic loading.

- Flakiness Index (FI)

A measure of the shape of aggregate particles, assessing how flaky or elongated they are.

- Specific Gravity

The ratio of the density of the aggregate to the density of water, indicating material compactness.

- Water Absorption

The percentage of water that the aggregate can absorb, affecting its performance in concrete.

- Durability

The ability of aggregates to withstand weathering and degradation over time.

- Adhesion with Bitumen

The bond between aggregate and bitumen, crucial for performance in asphalt works.

Reference links

Supplementary resources to enhance your learning experience.