Open-Loop Control Systems

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Open-Loop Control Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will be discussing open-loop control systems. Can anyone tell me what they think an open-loop control system is?

Is it a system that doesn't use any feedback?

Exactly! Open-loop control systems operate without feedback. This means they execute commands based solely on preset instructions without adjusting to inputs from their environment.

So they're not very flexible?

Right again! This lack of adaptability means they can be less precise compared to closed-loop systems. But they are often simpler and more cost-effective, which can be beneficial in certain applications.

Can you give an example of an open-loop control system?

A common example is a timer-based robotic arm. It performs tasks for a specific duration at set speeds, but it doesn’t adjust based on what it encounters in the environment.

That sounds useful for simple tasks!

Absolutely! But keep in mind the limitations, especially in complex environments where feedback would improve performance.

Advantages and Disadvantages of Open-Loop Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the advantages of open-loop control systems. Can anyone list some benefits?

They are cost-effective!

Exactly! They tend to be cheaper and easier to maintain than closed-loop systems. What else?

They are predictable since they follow a set program.

Correct! Predictability is a significant advantage. However, what do you think could be a disadvantage?

They can't correct errors during operation.

Yes, that's a key limitation. Without feedback, they can’t adjust to errors or changes in the environment. This can lead to performance issues.

In what situations would it make sense to use open-loop systems despite this?

Great question! Open-loop systems are ideal for well-defined tasks where the conditions remain consistent, like simple assembly line operations.

Applications of Open-Loop Control Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Can anyone think of industries or applications where open-loop control systems are commonly used?

Manufacturing lines?

That’s correct! Many manufacturing lines use open-loop systems for tasks that are repetitive and do not change. What might be a specific task performed?

Maybe in packing materials?

Yes, packing is a great example. They can quickly perform repetitive tasks, enhancing efficiency. Any other examples?

Could it be used in something like an irrigation system?

Good point! An irrigation system might use timer-based controls, which would fall under open-loop systems since it won’t adjust based on the moisture level in the soil.

This makes it clear why they are used in simpler tasks!

Limitations and Considerations When Using Open-Loop Control Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

While there are significant advantages, understanding the limitations of open-loop systems is critical. What limitations can you think of?

They can’t adapt to changes!

Correct! They are not suitable for conditions that change frequently. Can you provide an example of a scenario where this could cause problems?

In areas with variable weather for irrigation, it might lead to over or under-watering.

Exactly! Overwatering can cause plant damage. That’s why sometimes, even more advanced feedback systems are crucial several agriculture scenarios.

So, would you typically use them in complex robotics?

Not usually. Open-loop control systems are not preferred in robotics where precise movements are required. Closed-loop systems are better suited there.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Open-loop control systems are defined by their lack of feedback mechanisms. This simplicity often leads to cost-effectiveness, yet they lack the adaptability and precision of closed-loop systems. A typical example is a timer-based robotic arm that performs tasks without sensing its environment.

Detailed

Open-Loop Control Systems

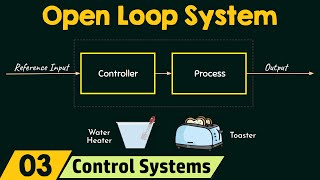

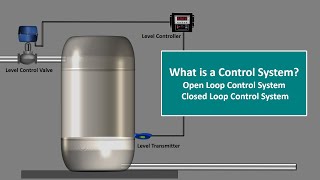

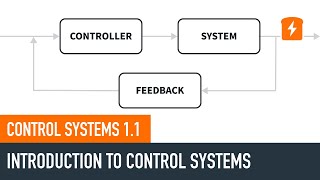

Open-loop control systems are control mechanisms that do not utilize feedback to adjust their operation. These systems execute commands based on predetermined settings without monitoring their output or the environment around them. While they are generally simpler and more cost-effective than closed-loop systems, they lack adaptability to changing conditions and cannot correct errors in real-time.

Key Characteristics

- No Feedback Mechanism: Open-loop systems do not receive data about their output performance or the environment. This means that any errors that occur during operation cannot be corrected instantly or at all.

- Cost-Effectiveness: Due to their simpler design and lower component requirements, open-loop systems tend to be cheaper to manufacture and maintain.

- Predictability: They perform tasks predictably without fluctuating performance due to external factors.

- Examples in Robotics: One significant example is a timer-based robotic arm programmed to move for a specific duration at a set speed, regardless of real-time environmental conditions or task requirements.

Significance

Open-loop systems serve essential functions in various applications, particularly where simplicity and cost-effectiveness are more critical than precision and adaptability. For instance, they can be used in manufacturing processes where tasks are well-defined and do not require adjustment post-deployment. However, understanding their limitations is vital for selecting the appropriate control system for specific tasks.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Open-Loop Control Systems

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Operate without feedback.

Detailed Explanation

Open-loop control systems are control systems that work without receiving feedback about their output. This means that once they've been set into operation, they do not modify their behavior based on the actual outcomes of their actions. Instead, they follow a predefined set of instructions regardless of whether those actions achieve the desired effect. For instance, if a robot is programmed to perform a task for a specific duration, it will carry out that task for that duration only, without adjusting its operation based on current conditions.

Examples & Analogies

Imagine setting a timer to bake a cake. Once you set the timer, it counts down without checking if the cake is actually baking properly. If the oven is too low or too high, the cake may not turn out as expected, but the timer will still go off after the set time regardless.

Simplicity and Cost-Effectiveness

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Simple and cost-effective, but not adaptive.

Detailed Explanation

One of the hallmark advantages of open-loop control systems is their simplicity. They require less complex hardware and software compared to feedback systems, making them typically more cost-effective. This simplicity often results in lower maintenance needs. However, the major drawback is that they do not adapt to changes in the environment or system performance. If conditions change, the open-loop system will continue to operate under the initial programmed settings without any corrections.

Examples & Analogies

Think of an automatic washing machine set to wash clothes for 30 minutes. If you forget to add detergent, the machine will still run for those 30 minutes, but the clothes may not get clean, illustrating the lack of adaptability.

Example of Open-Loop Control System

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Example: A timer-based robotic arm that moves for a set duration without sensing its environment.

Detailed Explanation

A practical example of an open-loop control system is a timer-based robotic arm. If programmed to pick up an object and then place it down in a specific location after a set time, the robotic arm does not check if the object is accurately picked up or whether there are any obstacles in the way. It simply executes the movement according to the pre-programmed instructions.

Examples & Analogies

Think of a child playing with a toy robot that moves in straight lines for a short distance. If the robot encounters a toy block in its path, it will bump into it and not know to stop or change direction, as it has no way of sensing the block. It just follows the given commands regardless of what happens in its surroundings.

Key Concepts

-

Open-Loop Control Systems: Systems that execute actions without feedback.

-

Cost-Effectiveness: The benefit derived from open-loop systems due to their simpler design.

-

Timer-Based Operations: Many open-loop systems operate based on predetermined timings.

Examples & Applications

A timer-controlled robotic arm moving for a fixed time period without adjusting based on the task demands.

Irrigation systems that water plants based on a timer rather than soil moisture levels.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Open-loop, no feedback in sight, actions pre-set, but not quite right.

Stories

Imagine a gardener who waters plants based on a clock. They set the timer but do not check the soil. Sometimes the garden is overwatered, and sometimes too dry. This gardener represents an open-loop system, predictable but not responsive.

Memory Tools

O-L: Operates-Loss of feedback.

Acronyms

OLCS

Open Loop Control System - Operate without feedback

Less flexibility.

Flash Cards

Glossary

- OpenLoop Control System

A type of control system that operates without feedback, executing commands based on predetermined settings.

- Feedback

The process of using data about a system's output to make adjustments to improve performance.

- CostEffectiveness

The efficiency of a system in terms of its costs, balancing performance and expense.

- Predictability

The ability to consistently achieve the same performance level under the same operating conditions.

- TimerBased Control

A control method where specific operations or movements are executed based on a timer rather than environmental input.

Reference links

Supplementary resources to enhance your learning experience.